Tel:

+8618931101301

Tel:

+8618931101301

Jul . 22, 2025 15:01 Back to list

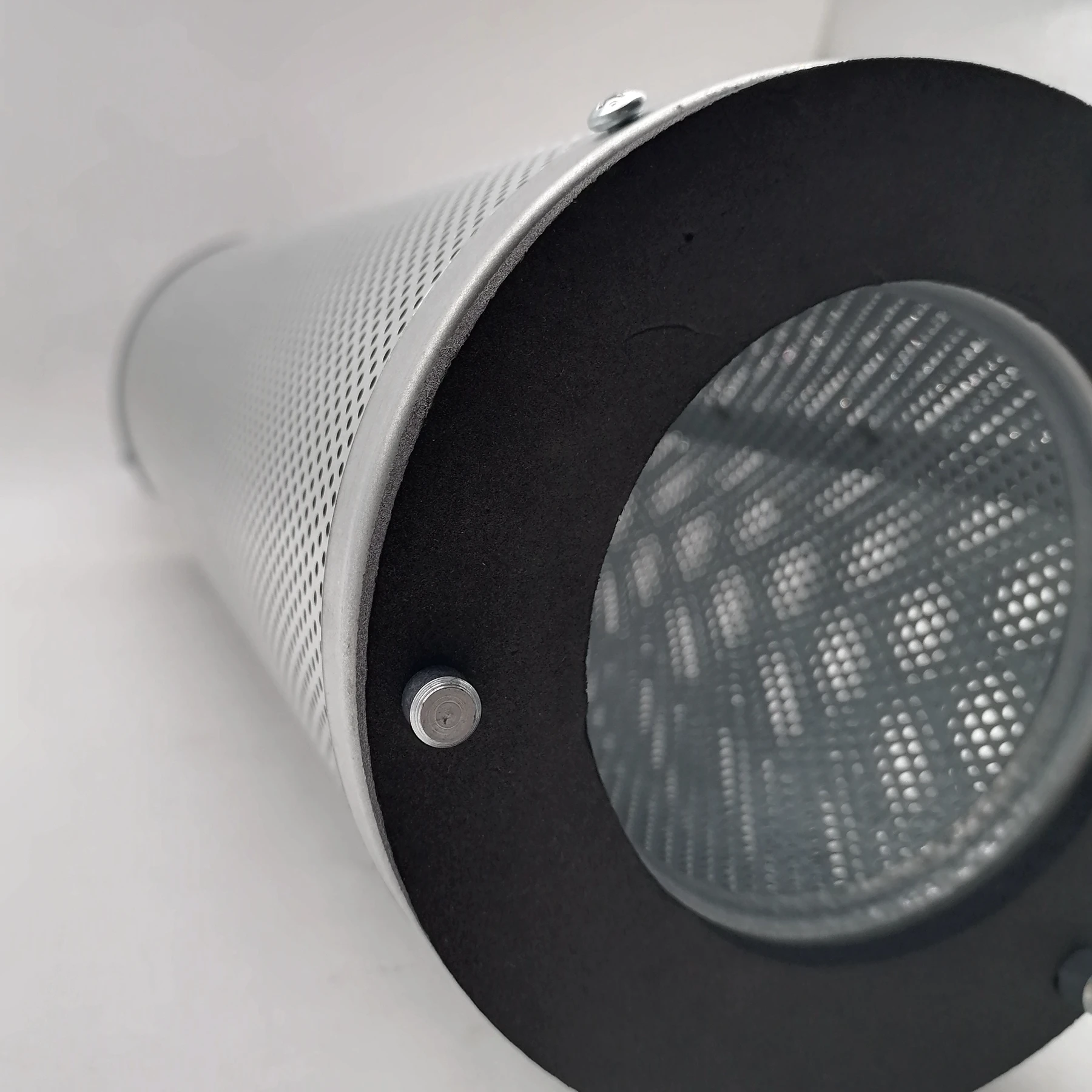

High Efficiency SS Filter Cartridge with Activated Carbon Filter Element

Phone/WhatsApp: +86 18931101301

Email: admin@only-filter.com

Address: Rongding World, Xinhua District, Shijiazhuang City, Hebei Province

The filtration industry is undergoing a transformative evolution, with ss filter cartridge (stainless steel filter cartridge) solutions at its forefront. As industrial, municipal, and residential users continue to demand higher purification accuracy and efficiency, advanced products like the activated carbon cartridge and activated carbon filter element have become mission-critical. Global trends show escalating adoption due to the need for compliance with ever-stringent water and air quality standards, growing public health awareness, and the push for sustainable purification methods (source).

Product Name: Customized Carbon Canister Adsorption of Chemical Pollutants Activated Carbon Air Filter Cartridge

Product Link: View Product Details >>

The activated carbon filter element is crafted using high-grade activated carbon, ensuring high adsorption capacity for a range of impurities, residual chlorine, and odors from water. Its superior filtration precision not only greatly improves water taste but also guarantees water safety — making it a prime choice for both household and office water purification applications.

Key Attributes: High filtration accuracy, robust removal of chemical contaminants, longevity, and compatibility with various purification systems.

| Parameter | Description | Typical Value |

|---|---|---|

| Material | 316L/304 Stainless Steel, Activated Carbon | 304SS, 316LSS, High-Quality Charcoal |

| Micron Rating | Filtration fineness | 0.22μm, 1μm, 5μm, 10μm, 25μm |

| Length | Cartridge length | 5", 10", 20", 30", 40" |

| OD/ID | Outer/Inner diameter | OD: 64mm, 69mm; ID: 28mm, 30mm |

| Maximum Pressure | Max operating pressure | 5 Bar / 72.5 psi |

| Max Temperature | Working temperature | 110°C (230°F) |

| pH Range | Chemical resistance | 2 – 13 |

| Filter Media | Core filtration substance | Activated Carbon + Stainless Steel Mesh |

- Municipal and Industrial Water Supply & Distribution

- Drinking Water Treatment Facilities

- Food & Beverage Manufacturing

- Pharmaceuticals & Biotech Labs (sterile filtration)

- Chemical & Petrochemical Plants

- Electronics/Ultrapure Water Systems

- Residential Purification Equipment

- Air Purification and Odor Control Equipment

Referencing use in multiple domains affirms the versatility and technical adaptability of the ss filter cartridge and related activated carbon filter element as validated by leading industry publications (Filtration+Separation).

1. What is the main material used in an ss filter cartridge?

The fundamental material is high-grade 304 or 316L stainless steel, often complemented with food-grade activated carbon cartridge beds for enhanced removal of organics and chlorine.

2. What is the typical micron rating of an ss filter cartridge?

Ranges from 0.22μm (suitable for bacteria and fine particle removal) up to 25μm for general industrial filtration. For precision drinking water purification, 1μm-5μm is standard.

3. How are activated carbon filter elements integrated into air or water systems?

These elements are typically fitted into filter housings using double open end (DOE) or single open end (SOE) designs, adhering to standard diameters and lengths for easy retrofitting.

4. What are the global installation standards for ss filter cartridge?

Compliance to WHO, NSF/ANSI-42, and EU EN standards is common. Always verify that sealing gaskets and end caps meet the chemical compatibility codes for the intended application (WQA Guidelines).

5. What determines the service life of an activated carbon cartridge?

The quantity and quality of activated carbon, influent pollutant load, and cartridge design parameters (surface area, bed depth) — typically from 9 to 15 months depending on use.

6. Does pressure drop affect ss filter cartridge efficiency?

Yes — excessive particulate loading increases pressure drop, reducing system throughput. Periodic monitoring and timely replacement are essential for ensuring optimal performance.

7. Are customized options (size, endcap, connector types) available?

Absolutely. ONLY Technology (hebei Province) Co., Ltd. offers full customization on size, endcap formats, and connector compatibility. Contact us (admin@only-filter.com) with your specific system requirements.

- Proven Expertise: Years of R&D and global project installations establish a high level of expertise for ss filter cartridge and activated carbon filter element products.

- Authoritativeness: Endorsed by international water quality associations and industry consortia for product quality and compliance.

- Trustworthiness: Transparent manufacturing, strict quality control, and a robust supply chain guarantee consistency. All claims are verifiable by third-party certifications and customer reviews.

- Dedicated Support: Professional consultation and after-sales services ensure a seamless and efficient experience from project consultation to delivery.

For more details, refer to the authoritative Filtration+Separation market report (source), and technical guidelines outlined on leading water purification forums (WaterTech Online).

ONLY Technology (hebei Province) Co., Ltd. – Innovating Filtration for Tomorrow.

- Filtration+Separation — Filter Cartridge Market Outlook

- WaterTech Online — Filtration Market Growth and Innovation

- Water Quality Association — Filter Certification and Standards

- ScienceDirect — Advances in Activated Carbon Filter Technology

- Home Water Works Forum — Activated Carbon Cartridge Practices

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: