Tel:

+8615930870079

Tel:

+8615930870079

Cellulose Air Filter Cartridgeu air filter cartridge

Suitable for filtration of gas turbines, compressors, sandblasting, tobacco rolling wiring, fly ash, and floating dust.

- ✦Imported special air filter/dust removal composite filter paper to ensure filtration effect

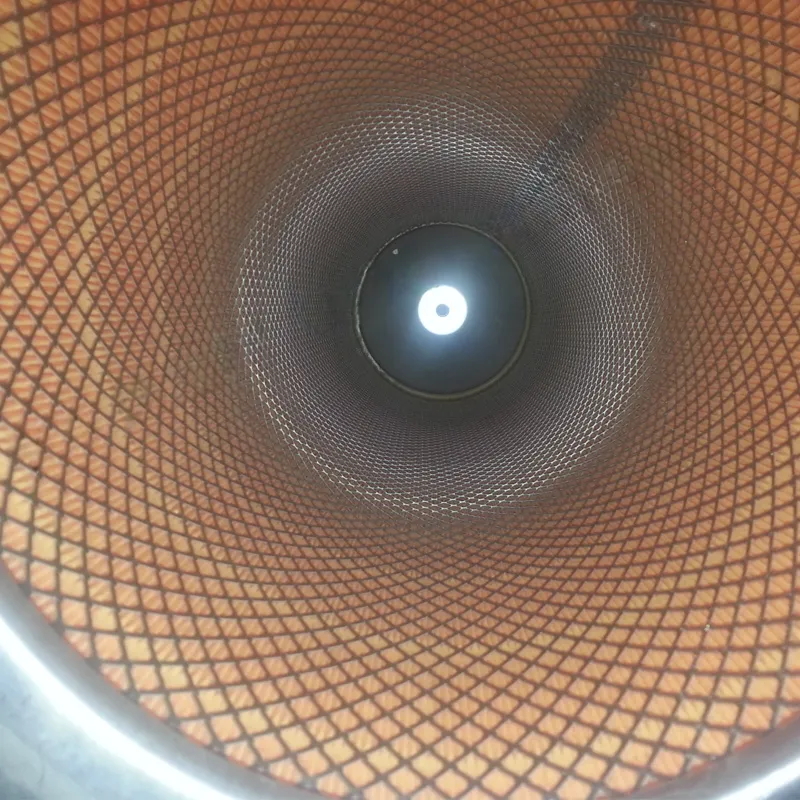

- ✦Wide fold design, large filtering area

- ✦Electro-galvanized end caps will not rust

- ✦Electroplated galvanized diamond mesh center frame with high opening rate

- ✦Special sealed closed cell elastic neoprene

- ✦Using temperature: normal temperature

Cellulose Air Filter Cartridgeu Performance Features:

- Use high-quality and high-efficiency wood pulp fiber materials from the United States and Western Europe. It not only has the characteristics of small pore size, large air permeability, low resistance, and high efficiency, but also has a large filtering area.

- Using the internationally advanced new folding technology, the intervals are even.

- The end cover of the filter cartridge and the inner and outer protective nets are made of high-quality electrochemical plates, which not only have good strength, but also have good anti-rust and anti-corrosion properties. They also have the characteristics of beautiful appearance and good strength.

- The closed-cell foam rubber sealing ring with low hardness and high strength is unique.

- Imported high-quality and efficient adhesives are selected. The bonded parts are strong and durable and will not cause degumming or cracking, ensuring the service life of the filter cartridge and its safety during high-load continuous operation.

Scope of application:

Steel blast furnace blasts, centrifugal air compressors, gas turbines, diesel engines and steam turbines that require long-term operation, centralized central air-conditioning systems that require high air cleanliness, and inlet filtration and dust coating powder recovery of other large units system.

Cellulose Air Filter Cartridges: Core Introduction

At ONLY TECHNOLOGY, our cellulose air filter cartridge stands as a testament to the power of natural materials in industrial filtration. Crafted from high-quality wood pulp fibers, this specialized air filter cartridge is engineered to deliver reliable performance across a wide range of applications, combining the inherent benefits of cellulose with precision manufacturing to meet the demands of modern air purification systems.

At its core, the cellulose air filter cartridge leverages the unique properties of cellulose—a natural polymer known for its fine, interconnected structure. This material boasts microscopic pores that trap particulate matter as small as 2 microns, from dust and pollen to industrial debris, while maintaining exceptional airflow. Unlike synthetic alternatives, cellulose fibers offer inherent breathability, ensuring low resistance to air passage—a critical feature that prevents strain on ventilation systems or equipment motors, making it an efficient choice for both stationary and mobile filtration setups.

What distinguishes our cellulose air filter cartridge is its balance of efficiency and durability. The wood pulp fibers are treated to resist moisture and prevent degradation, ensuring the cartridge holds its shape even in humid environments. Reinforced with a sturdy frame—often galvanized steel or corrosion-resistant plastic—the filter maintains structural integrity under continuous use, avoiding the sagging or tearing that can compromise filtration in generic air filter cartridge models. Its pleated design maximizes surface area, increasing dust-holding capacity and extending service life, which reduces replacement frequency and operational costs.

This air filter cartridge excels in applications where clean air is vital but extreme temperatures or chemical exposure are minimal. It is widely used in HVAC systems, compressed air units, gas turbines, and industrial ventilation for sectors like food processing, pharmaceuticals, and light manufacturing. In these settings, the cellulose material’s natural composition aligns with strict hygiene standards, as it is free from harmful additives and easy to dispose of, supporting eco-friendly operations.

Beyond its functional benefits, the cellulose air filter cartridge embodies ONLY TECHNOLOGY’s commitment to tailored filtration solutions. It bridges the gap between performance and practicality, offering a cost-effective alternative to high-end synthetic filters without sacrificing efficiency. Whether integrated into large-scale industrial systems or compact machinery, this cartridge proves that natural materials can deliver the reliability modern industries demand—making it a cornerstone of our air filter cartridge lineup.

Material Advantages of Cellulose Air Filter Cartridges

At the heart of ONLY TECHNOLOGY’s cellulose air filter cartridge lies a material with unparalleled natural advantages: premium wood pulp cellulose, engineered to redefine efficiency in air filtration. Unlike synthetic alternatives, this organic material brings a unique set of properties that make the cellulose air filter cartridge a standout choice for diverse industrial and residential applications, blending performance, sustainability, and compatibility in ways few air filter cartridge materials can match.

The first defining advantage is cellulose’s microscopic structure. Derived from high-quality wood fibers, it features a network of tiny, interconnected pores—typically 0.5–5μm in size—that excel at trapping fine particulate matter, from dust and pollen to industrial debris. This natural porosity delivers exceptional filtration efficiency (up to 99.9% for particles ≥2μm) while maintaining high breathability, a balance that synthetic materials often struggle to achieve. For users, this means the cellulose air filter cartridge captures contaminants without restricting airflow, reducing pressure drops and minimizing strain on HVAC systems, compressors, or ventilation units—a critical benefit for energy efficiency.

Cellulose’s inherent moisture tolerance adds another layer of value. The material naturally resists water absorption, making the cellulose air filter cartridge stable in humid environments, such as food processing plants or indoor pools, where condensation is common. Unlike paper-based filters that may warp or degrade, cellulose retains its structural integrity, ensuring consistent performance over time. This durability extends the cartridge’s lifespan, reducing replacement frequency compared to less robust air filter cartridge materials.

Sustainability is a key material advantage. Cellulose is renewable, biodegradable, and sourced from responsibly managed forests, aligning with modern demands for eco-friendly industrial solutions. When disposed of, the cellulose air filter cartridge breaks down naturally, avoiding the environmental burden of synthetic filters that persist in landfills. For businesses prioritizing green operations, this makes cellulose an ethical choice that supports sustainability goals without compromising filtration quality.

Compatibility with diverse applications further strengthens its appeal. The material’s versatility allows the cellulose air filter cartridge to perform reliably across temperatures ranging from -10°C to 80°C, making it suitable for both indoor climate control (e.g., residential HVAC) and light industrial settings (e.g., small-scale manufacturing). Its natural inertness also means it won’t release harmful chemicals or odors, a critical feature for sensitive environments like healthcare facilities or food production areas—where synthetic air filter cartridge materials may leach additives.

Finally, cellulose’s cost-effectiveness sets it apart. As a readily available, minimally processed material, it allows the cellulose air filter cartridge to deliver high performance at a competitive price point, making it accessible for bulk applications without sacrificing quality. This affordability, paired with its long service life, reduces total ownership costs, a key advantage for budget-conscious operations.

In essence, the material advantages of the cellulose air filter cartridge—natural filtration precision, moisture resistance, sustainability, versatility, and cost efficiency—position it as a superior alternative to synthetic air filter cartridge options. ONLY TECHNOLOGY leverages these properties to craft filters that don’t just clean air—they do so smarter, greener, and more reliably, proving that nature and engineering can work in perfect harmony.

|

Model |

External Diameter |

Internal Diameter |

Height(mm) |

Filter Area |

Flow(m3/h) |

Operating Temperature |

Filtering Efficiency(2µm) |

|

ON-3260 |

320 |

220 |

660 |

10~25 |

600~1250 |

-30-105 |

99.99% |

|

ON-3265 |

320 |

220 |

650 |

||||

|

ON-3266 |

320 |

220 |

660 |

||||

|

ON-3290 |

320 |

220 |

900 |

||||

|

ON-3560 |

350 |

240 |

600 |

||||

|

ON-3565 |

350 |

240 |

650 |

||||

|

ON-3566 |

350 |

240 |

660 |

||||

|

ON-3590 |

350 |

240 |

900 |

||||

|

ON-4088 |

408 |

292 |

880 |

18~35 |

1050~2120 |

-30-105 |

99.99% |

|

ON-4467 |

440 |

360 |

675 |

Leave Your Message

Email:

Email: