Tel:

+8618931101301

Tel:

+8618931101301

Sep . 21, 2024 22:26 Back to list

dust cartridge

Understanding Dust Percentage in Cartridge Performance

In the realm of manufacturing and machinery, the importance of maintaining optimal performance cannot be overstated. One critical factor that contributes to machine efficiency and durability is the quality of the dust cartridge used in various applications, particularly within filtration systems. The dust percentage or dust% of a cartridge serves as a key metric in evaluating its effectiveness and suitability for specific tasks.

A dust cartridge functions as a vital component in air filtration systems, industrial dust collection units, and even automotive applications

. Its primary role is to capture and retain particulate matter - dust, dirt, and other airborne pollutants - thereby ensuring cleaner air and protecting machinery from contamination. The efficiency of a dust cartridge is often quantified by the dust percentage, which indicates the quantity of particulate matter the cartridge can filter out relative to the total volume of air processed.The dust percentage can vary significantly according to the design and materials used in the cartridge. High-quality cartridges often boast lower dust percentages, meaning they can capture a greater volume of dust particles while allowing cleaner air to pass through. Conversely, cartridges with higher dust percentages may be less efficient, allowing a significant portion of contaminants to escape back into the environment.

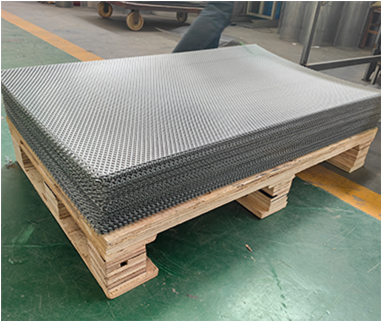

dust cartridge

Several factors influence the dust percentage of a cartridge, including the filtration media, the design of the cartridge, and the operational conditions. For instance, HEPA (High-Efficiency Particulate Air) filters are renowned for their impressive dust percentages, capturing 99.97% of particles that are 0.3 microns in size. This makes them an ideal choice for applications requiring sterile environments or those that deal with hazardous materials.

Choosing the right dust cartridge with an appropriate dust percentage is crucial for any operation. A cartridge that does not meet the specific needs of a facility can lead to increased maintenance costs, reduced efficiency, and potential equipment failure. For instance, a factory that generates fine dust through machining processes may require cartridges with higher dust-holding capacities and lower dust percentages. Conversely, an office environment may prioritize lower air resistance and noise levels, making different specifications necessary.

Additionally, regular monitoring and maintenance of dust cartridges can significantly impact their performance. Over time, dust cartridges can become saturated, leading to decreased airflow and efficiency. Maintaining an acceptable dust percentage ensures that the cartridge functions effectively and extends its lifespan. Operators should establish a routine schedule for inspecting and replacing cartridges based on the levels of dust and contaminants present in their environments.

In summary, understanding the concept of dust percentage in cartridges is essential for anyone involved in the maintenance of filtration systems or dust collection units. By selecting cartridges with optimal dust percentages tailored to specific operational needs and maintaining them effectively, industries can enhance their efficiency, reduce operational costs, and promote a healthier environment. As technology continues to advance, new materials and designs will emerge, potentially offering even better dust filtration capabilities, making it an exciting field to watch.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: