Tel:

+8615930870079

Tel:

+8615930870079

Sep . 21, 2024 22:08 Back to list

vacuum filter cartridge

The Role of Vacuum Filter Cartridges in Modern Filtration Systems

Vacuum filter cartridges play a crucial role in a variety of industrial and environmental processes, effectively separating solids from liquids and ensuring product purity. As industries evolve and the demand for efficient filtration systems grows, understanding the functionality and applications of vacuum filter cartridges becomes increasingly essential.

What are Vacuum Filter Cartridges?

At its core, a vacuum filter cartridge is a cylindrical filtration device designed to utilize vacuum pressure for the separation of solid particles from a liquid medium. The process relies on a combination of physical force and gravity, allowing liquids to pass through filter media while retaining solid particles. This method is particularly advantageous due to its efficiency and effectiveness in handling a wide range of fluids, including sludge, wastewater, and various industrial effluents.

Design and Materials

Vacuum filter cartridges are typically constructed from durable, chemical-resistant materials such as polypropylene, stainless steel, or specialty alloys, depending on the application and the properties of the fluids being processed. The filtration media within the cartridges can vary, consisting of synthetic fibers, woven fabrics, or porous materials designed to optimize filtration efficiency and flow rates. The choice of materials is critical to ensure longevity and resistance to chemical degradation.

Applications Across Industries

The versatility of vacuum filter cartridges allows them to be used across numerous industries, including

1. Municipal Water Treatment They are commonly employed in the treatment of drinking water and wastewater, where effective solid-liquid separation is essential to meet regulatory standards and protect public health.

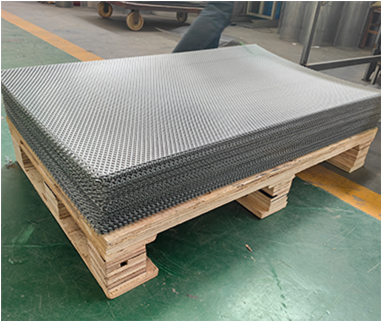

vacuum filter cartridge

2. Pharmaceuticals In pharmaceutical manufacturing, maintaining product purity is vital. Vacuum filter cartridges are used to ensure that contaminants are removed from raw materials, thereby safeguarding the quality of medicines.

3. Food and Beverage The food industry relies on vacuum filtration for the clarification of juices, beer, and other liquids. This process not only enhances product appearance but also extends shelf life.

4. Chemical Processing In the chemical sector, these cartridges are used to separate catalysts, precipitates, and other solids that can interfere with production processes, ensuring a streamlined operation.

5. Mining and Minerals Many mining processes require effective solid-liquid separation of slurries. Vacuum filter cartridges allow for the recovery of valuable minerals while minimizing waste.

Advantages of Vacuum Filter Cartridges

The adoption of vacuum filter cartridges presents numerous advantages. Firstly, they provide a more efficient filtration process, often requiring less time and energy compared to traditional methods. Secondly, the vacuum pressure enhances the flow rate, allowing for higher throughput and reduced downtime. Furthermore, the design of these cartridges ensures easy replacement and maintenance, contributing to lower operational costs.

Conclusion

As industries strive for greater efficiency and environmental sustainability, vacuum filter cartridges stand out as an indispensable technology in modern filtration systems. With their ability to provide effective separation across diverse applications, they help businesses optimize processes, meet regulatory requirements, and produce high-quality products. As technology advances, the continued innovation in filtration solutions, including vacuum filter cartridges, promises to play a pivotal role in meeting the unique challenges faced by various industries in the years to come.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: