Tel:

+8618931101301

Tel:

+8618931101301

พ.ย. . 09, 2024 01:03 Back to list

Optimizing Performance with Advanced Metal Filter Elements for Industrial Applications

Understanding Metal Filter Elements Importance, Types, and Applications

Metal filter elements are critical components in various industrial processes, especially where filtration is essential to ensure product purity, operational efficiency, and equipment protection. These filter elements are designed to separate solids from liquids or gases, making them invaluable in industries such as pharmaceuticals, food and beverage, oil and gas, and manufacturing.

The Importance of Metal Filter Elements

Metal filter elements offer several advantages over traditional filter materials like paper or cloth. They possess enhanced durability, robustness, and resistance to high temperatures and pressures. Unlike their counterparts, metal filters can withstand harsh environments and can be cleaned and reused, leading to significant cost savings over time. Their ability to operate under extreme conditions makes them suitable for applications where other materials would fail.

Furthermore, metal filters are capable of handling higher flow rates and offer a lower pressure drop across the filter medium. This is particularly important in industrial applications where maintaining operational efficiency is crucial. These filters can also provide precise filtration down to very fine particle sizes, which is essential for applications requiring stringent purity standards.

Types of Metal Filter Elements

Metal filter elements come in various types, each designed for specific applications or filtering requirements

. Here are some common types1. Sintered Metal Filters These filters are made by sintering metal particles together to create a porous structure. Sintered metal filters are highly effective at removing particles from fluids and gases and are often used in high-temperature applications.

2. Stainless Steel Mesh Filters Made from woven stainless steel, these filters are known for their corrosion resistance and strength. They are commonly used in the food and beverage industry, where hygiene and resistance to chemical reactions are paramount.

3. Expanded Metal Filters These filters are created from sheets of metal that are cut and stretched to form a mesh. They are lightweight, durable, and suitable for applications requiring good flow rates with moderate filtration capabilities.

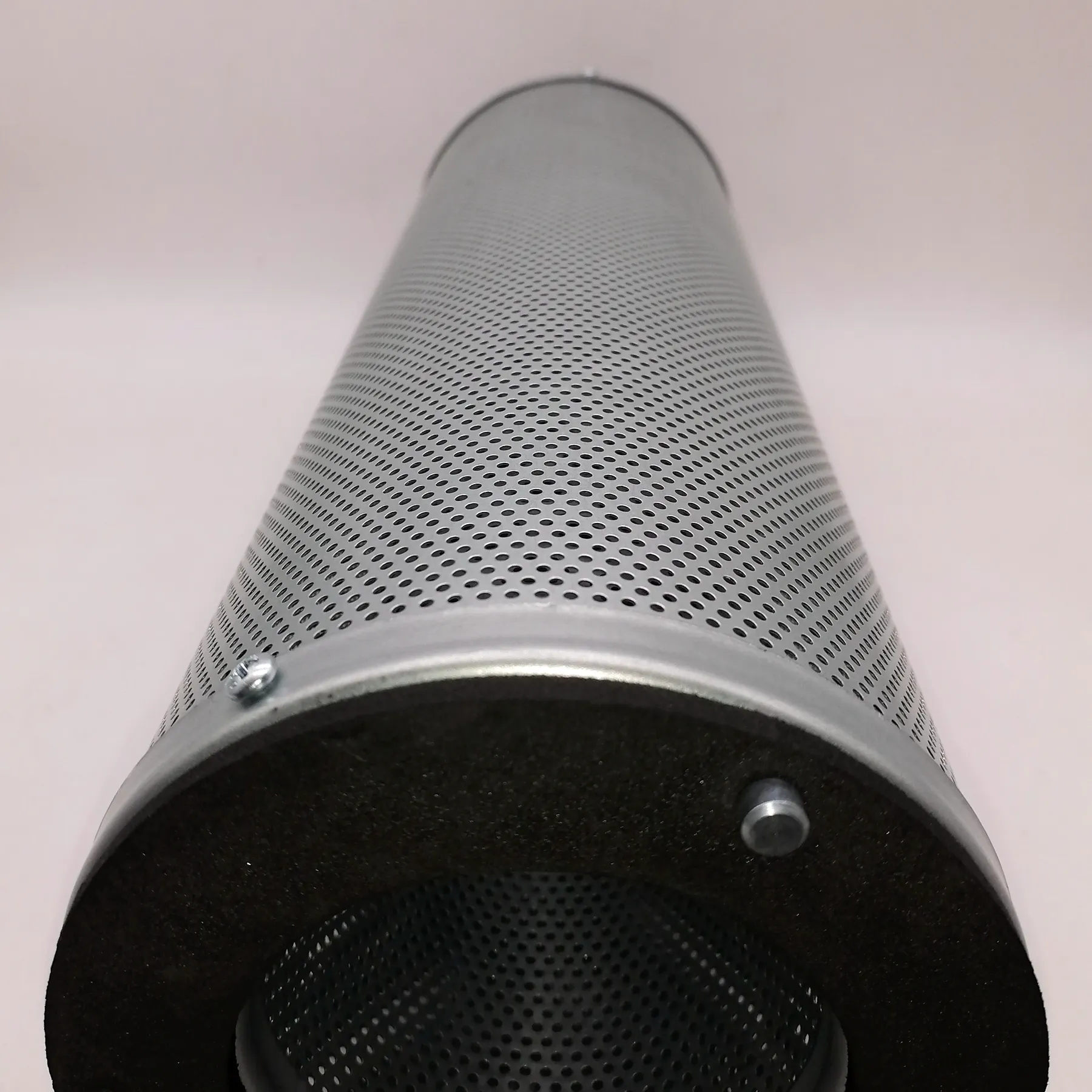

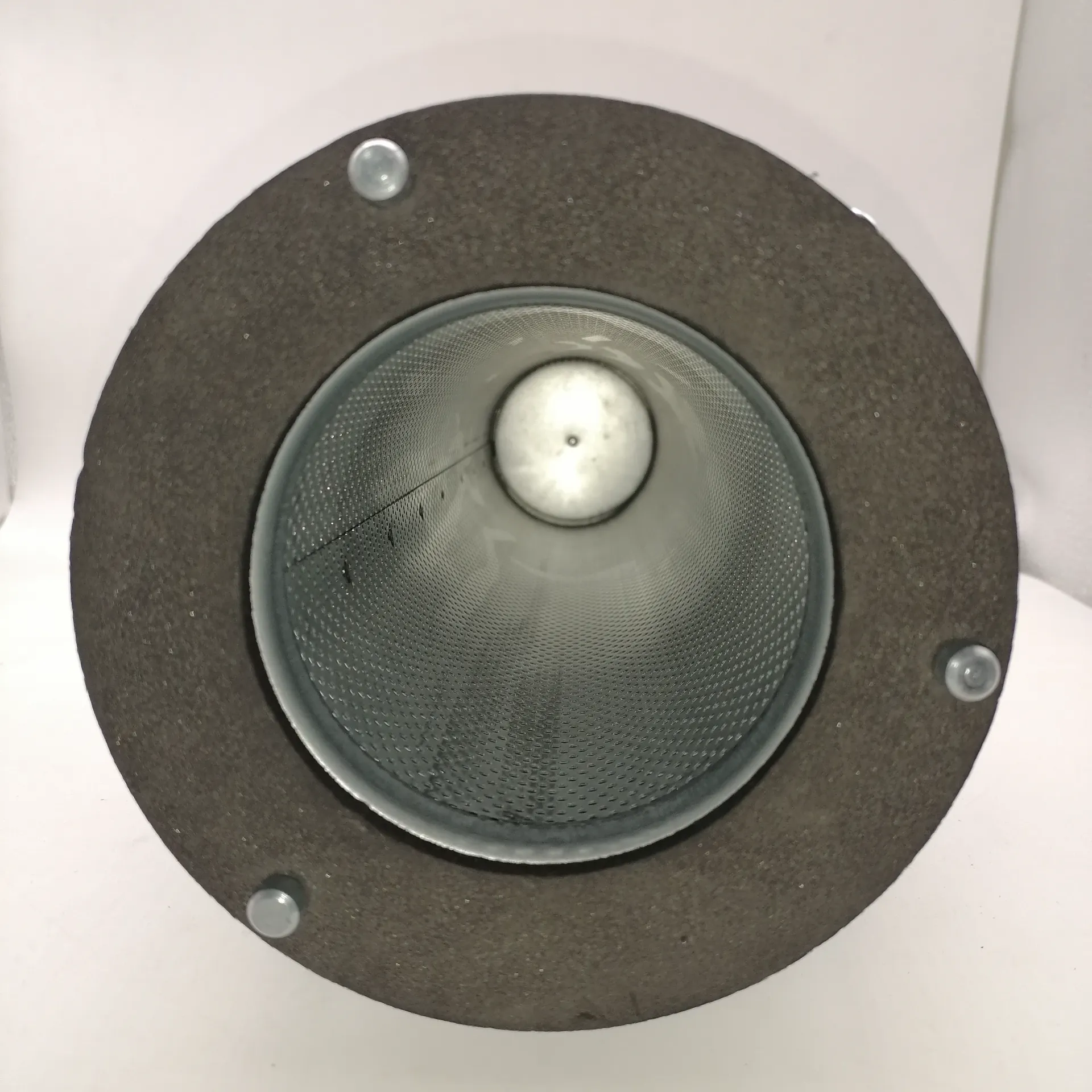

metal filter element

4. Ceramic Metal Filters Combining the properties of ceramics and metals, these filters are particularly effective in high-temperature and corrosive environments. They are often used in applications like gas filtration and petrochemical processes.

5. Wire Cloth Filters These consist of interwoven strands of metal wire, providing a sturdy yet flexible filtration solution. Wire cloth filters can be custom-designed for specific applications, making them versatile for many industrial uses.

Applications of Metal Filter Elements

Metal filter elements are utilized across a broad spectrum of applications. In the oil and gas industry, they are used to filter out impurities from fuels and chemicals during processing and transportation. This ensures the purity of the products and protects equipment from damage caused by particulates.

In the food and beverage sector, metal filters are essential for maintaining hygiene and quality. They are used during the production of beverages, oils, and other food products to remove contaminants, ensuring compliance with health regulations.

Pharmaceutical manufacturing also relies heavily on metal filter elements. In this industry, the need for sterile, uncontaminated products is critical. Metal filters help ensure that production processes maintain the highest standards of cleanliness and efficacy.

Additionally, in manufacturing operations involving abrasive materials or chemicals, metal filters are crucial for extending the life of machinery by preventing particulate contamination in lubricants and coolants.

Conclusion

In summary, metal filter elements are indispensable in various industrial applications due to their durability, efficiency, and adaptability to extreme conditions. Their ability to provide precise filtration while being reusable makes them an attractive option for businesses looking to enhance operational efficiency and reduce costs. As industries continue to evolve and demand higher quality and safety standards, the importance of metal filter elements will only continue to grow, solidifying their place as essential components in modern manufacturing and processing environments.

-

Will the activated carbon filter "vomit" pollutants after being used for a long time?NewsMay.15,2025

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

Email:

Email: