Tel:

+8618931101301

Tel:

+8618931101301

Set . 02, 2024 12:17 Back to list

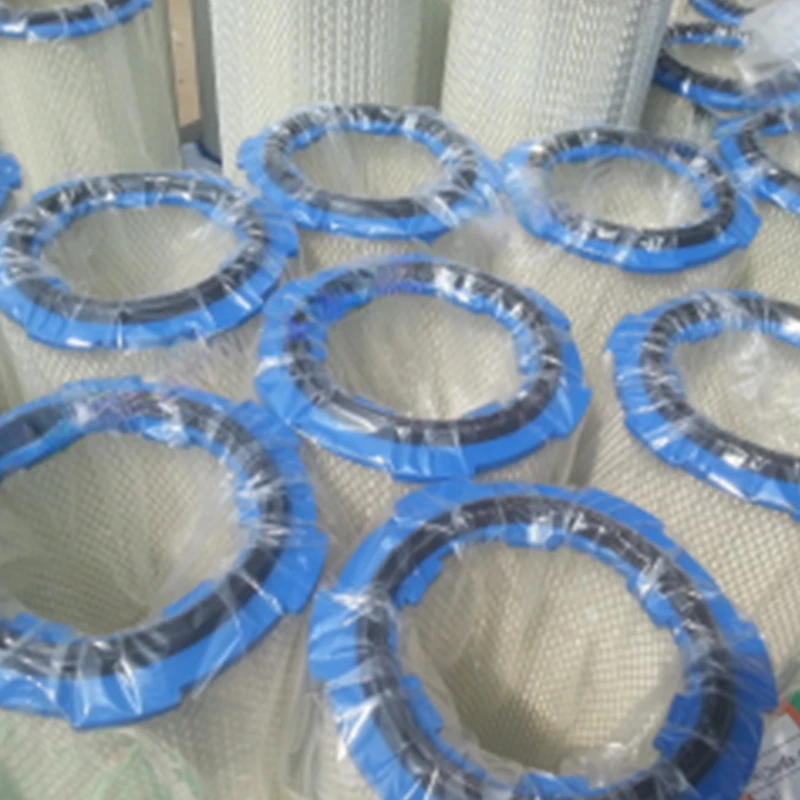

High-Efficiency Filter Cartridge Dust Collector | Industrial Air Filtration Solutions

Understanding Filter Cartridges in Dust Collectors Enhancing Air Quality and Operational Efficiency

In industries where dust and particulate matter are prevalent, maintaining a clean and safe working environment is paramount. One key component in achieving this is the dust collector, specifically through the use of filter cartridges. These cartridges play a vital role in ensuring air quality while enhancing the overall efficiency of dust collection systems.

What Are Filter Cartridges?

Filter cartridges are cylindrical filtration devices designed to capture dust and particulates from the air. Typically made from various materials such as polyester, cellulose, or pleated fabric, these cartridges are engineered to provide high filtration efficiency while promoting airflow. Their design allows for a large surface area, facilitating the collection of fine dust particles without significantly restricting air movement.

Importance of Dust Collection

Dust collection is essential not just for compliance with health and safety regulations but also for the protection of machinery and the creation of a healthier workplace. Excess dust can lead to respiratory problems for workers and damage equipment, potentially causing downtime and costly repairs. Efficient dust collection systems equipped with high-quality filter cartridges help mitigate these risks, providing cleaner air and a safer work environment.

How Filter Cartridges Function

The operation of filter cartridges in a dust collector is relatively straightforward. As air contaminated with dust enters the dust collector, it passes through the filter cartridge. Particulates are trapped on the surface or within the folds of the cartridge material while clean air is allowed to flow through. Over time, as more dust accumulates, the filter may become clogged, which is why regular maintenance and timely replacement of filter cartridges are crucial.

Factors to Consider When Choosing Filter Cartridges

filter cartridge dust collector

When selecting filter cartridges for a dust collector, several factors should be considered

1. Material Type Different materials offer varying benefits in terms of filtration efficiency, durability, and resistance to chemicals. Polyester is commonly used for general applications, while specialized materials may be required for specific industries.

2. Filtration Efficiency The efficiency rating of a filter cartridge determines its ability to capture specific particle sizes. Higher efficiency filters may be more appropriate for environments with fine dust or hazardous materials.

3. Size and Pleat Count The dimensions and number of pleats in a cartridge affect both airflow and the surface area available for dust collection. More pleats typically result in a larger surface area, which can enhance dust holding capacity and extend the time between replacements.

4. Application Different industrial settings may require distinct filter characteristics. For example, a woodworking facility may need a different filter than a manufacturing plant that deals with chemical dust.

Maintenance and Replacement

While filter cartridges are designed for durability, regular inspection and maintenance are essential to ensure consistent performance. Indicators such as increased pressure drop across the filter or reduced airflow can signal the need for cleaning or replacement. Proper care not only extends the life of the filter cartridges but also maximizes the efficiency of the dust collector system overall.

In conclusion, filter cartridges are a critical component of effective dust collection systems. By ensuring that the correct type of cartridge is chosen and maintained, businesses can protect their workforce, reduce equipment wear, and comply with environmental regulations, all while improving air quality in their operational environments. Investing in high-quality filter cartridges leads to long-term benefits in productivity and health for both employees and the organization as a whole.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: