Tel:

+8615930870079

Tel:

+8615930870079

Nov . 24, 2024 19:15 Back to list

vacuum filter cartridge

Understanding Vacuum Filter Cartridges Essential Components in Filtration Systems

In various industries, the demand for effective filtration techniques is paramount, especially in sectors like pharmaceuticals, food and beverage, wastewater treatment, and manufacturing. Among the myriad of filtration solutions available, vacuum filter cartridges stand out due to their efficiency and reliability. This article delves into the significance of vacuum filter cartridges, their design, applications, and benefits.

What is a Vacuum Filter Cartridge?

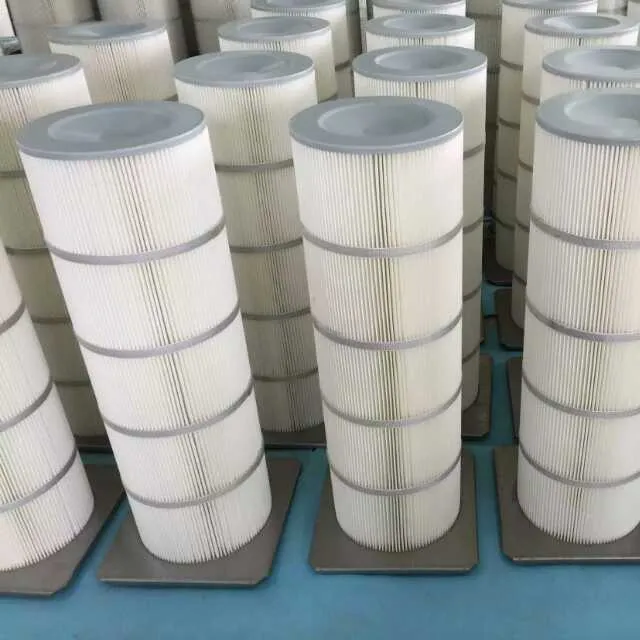

A vacuum filter cartridge is a cylindrical device designed to remove solid particles from liquids or gases using a vacuum suction process. These cartridges are commonly employed in filtration systems to ensure that contaminants are effectively trapped while allowing the clean fluid to pass through. The fundamental principle of operation relies on creating a vacuum that draws the liquid through the filter medium, which retains the suspended solids.

Design and Construction

Vacuum filter cartridges come in various designs, each tailored to specific filtration needs. Typically, they consist of a filter media, which may be made from materials such as polypropylene, polyester, or glass fiber. The choice of material depends on factors like the nature of the fluid being filtered, the particle size, and the operating conditions. The filter media is often housed in a durable shell that can withstand the vacuum pressure and provide structural integrity.

Several designs enhance the cartridge's performance, including pleated configurations that increase the surface area for filtration, thus allowing for a higher flow rate and longer service life. Additionally, end caps and gaskets are often employed to ensure a proper seal, preventing any unfiltered fluid from bypassing the cartridge.

Applications in Various Industries

Vacuum filter cartridges are incredibly versatile and find applications in numerous industries

1. Pharmaceuticals In the production of drugs, maintaining the purity of solvents and solutions is crucial. Vacuum filter cartridges are employed to ensure that any contaminants are removed, thus adhering to stringent regulatory standards.

2. Food and Beverage In food processing, ensuring product safety is of utmost importance. Vacuum filter cartridges are used in the clarification of juices, the filtration of oils, and the purification of water, helping to eliminate unwanted particles that could affect taste and quality.

vacuum filter cartridge

3. Wastewater Treatment Filtering contaminants from wastewater is essential for environmental protection. These cartridges play a vital role in removing solids before the water is treated or discharged back into nature.

4. Manufacturing Various manufacturing processes require liquid filtration to maintain equipment efficiency and product quality. Vacuum filter cartridges help in filtering coolants, oils, and other fluids used in production.

Benefits of Using Vacuum Filter Cartridges

1. Efficiency The vacuum process accelerates the filtration rate, leading to reduced processing times. This efficiency is crucial in industries where throughput is essential.

2. Cost-Effective While the initial cost of vacuum filter cartridges might be higher than other filtration options, their effectiveness in preventing equipment damage and reducing downtime makes them a cost-efficient choice in the long run.

3. Versatility Available in different sizes and configurations, vacuum filter cartridges can be customized to suit specific applications, making them adaptable to various filtration needs.

4. Ease of Maintenance These cartridges are designed for easy replacement and cleaning, minimizing downtime and maintenance costs for industries that rely heavily on filtration systems.

5. Improved Product Quality By effectively removing contaminants, vacuum filter cartridges contribute to better quality products, enhancing customer satisfaction and regulatory compliance.

Conclusion

Vacuum filter cartridges are a cornerstone of modern filtration systems across various industries. Their ability to efficiently and effectively remove contaminants from liquids and gases makes them indispensable in maintaining product quality and safety. With advancements in materials and design, these cartridges are becoming even more efficient and versatile, enhancing their value in industrial applications. Whether in pharmaceuticals, food processing, wastewater treatment, or manufacturing, vacuum filter cartridges continue to play a critical role in ensuring operational excellence and compliance with industry standards.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: