Tel:

+8615930870079

Tel:

+8615930870079

Nov . 10, 2024 12:55 Back to list

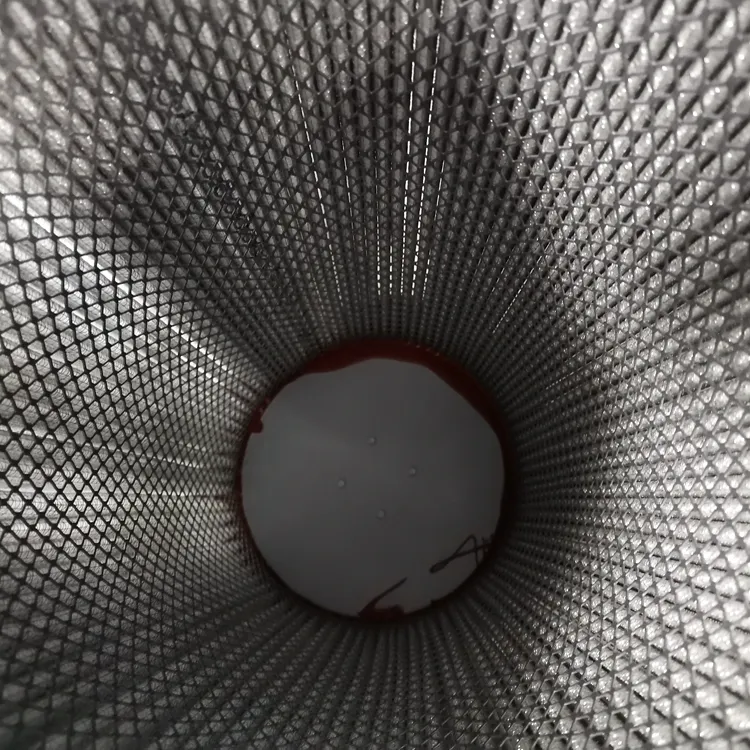

Efficient Vacuum Filter Cartridge for Enhanced Filtration Performance and Longevity

Understanding Vacuum Filter Cartridge Systems

In various industrial and environmental applications, the need for efficient filtration systems is paramount. One such system that has gained popularity in recent years is the vacuum filter cartridge. This article delves into the mechanics, applications, and advantages of vacuum filter cartridge systems.

What is a Vacuum Filter Cartridge?

A vacuum filter cartridge is a critical component in filtration systems that utilize vacuum pressure to separate solid particles from liquids or gases. This technology harnesses the power of vacuum to enhance the filtration process, making it more effective and efficient compared to traditional filtration methods. The cartridge itself usually consists of a porous medium that captures solid impurities while allowing clean fluid or gas to pass through.

How Does It Work?

The operation of a vacuum filter cartridge is straightforward yet highly effective. The process begins when a vacuum is created in the filtration unit. This vacuum generates a pressure differential that forces the liquid or gas through the cartridge. As the fluid passes through the filter medium, solid particles are trapped inside, resulting in a purified output.

The efficiency of filtration can be influenced by various factors, including the characteristics of the medium used in the cartridge, the size of the particles being filtered, and the rate of flow. The design of the cartridge also plays a crucial role in determining the overall performance of the filtration system.

Applications of Vacuum Filter Cartridges

Vacuum filter cartridges are employed across various sectors due to their effective filtration capabilities. Some common applications include

1. Water Treatment In municipal and industrial water treatment facilities, vacuum filter cartridges help remove contaminants and improve water quality before it is released into the environment or distributed for consumption.

2. Food and Beverage Industry These cartridges ensure that products are free from particulates, ensuring safety and compliance with health regulations. Applications include juice clarification, beer filtration, and oil purification.

vacuum filter cartridge

3. Pharmaceutical Manufacturing In the pharmaceutical sector, stringent standards require the removal of contaminants to ensure product safety and efficacy. Vacuum filter cartridges provide the necessary level of filtration to meet these standards.

4. Chemical Processing The chemical industry benefits from vacuum filter cartridges by maintaining product purity and preventing contamination during manufacturing processes.

5. Environmental Remediation In the context of cleaning contaminated sites, vacuum filtration systems are used to extract pollutants from soil and groundwater efficiently.

Advantages of Vacuum Filter Cartridges

The adoption of vacuum filter cartridges in various applications offers several advantages

- Higher Efficiency The use of a vacuum improves the filtration speed and efficiency, allowing for faster processing times compared to gravity-fed systems.

- Fine Filtration These cartridges can achieve finer filtration levels, effectively removing smaller particles that might pass through other filtration methods.

- Reduced Maintenance Many vacuum filter cartridges are designed to be modular and easy to replace, minimizing downtime and maintenance effort for operators.

- Versatility Vacuum filter cartridges can be tailored to meet specific filtration needs, making them suitable for a wide range of applications and industries.

Conclusion

As industries strive for improved efficiency and sustainability, vacuum filter cartridge systems represent a reliable solution for effective filtration. Their wide-ranging applications, combined with their advantages in efficiency and maintenance, make them an increasingly popular choice among manufacturers and service providers. With ongoing advancements in filtration technology, vacuum filter cartridges will likely continue to play an essential role in ensuring clean processes and products across various sectors.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: