Tel:

+8615930870079

Tel:

+8615930870079

Dec . 12, 2024 09:29 Back to list

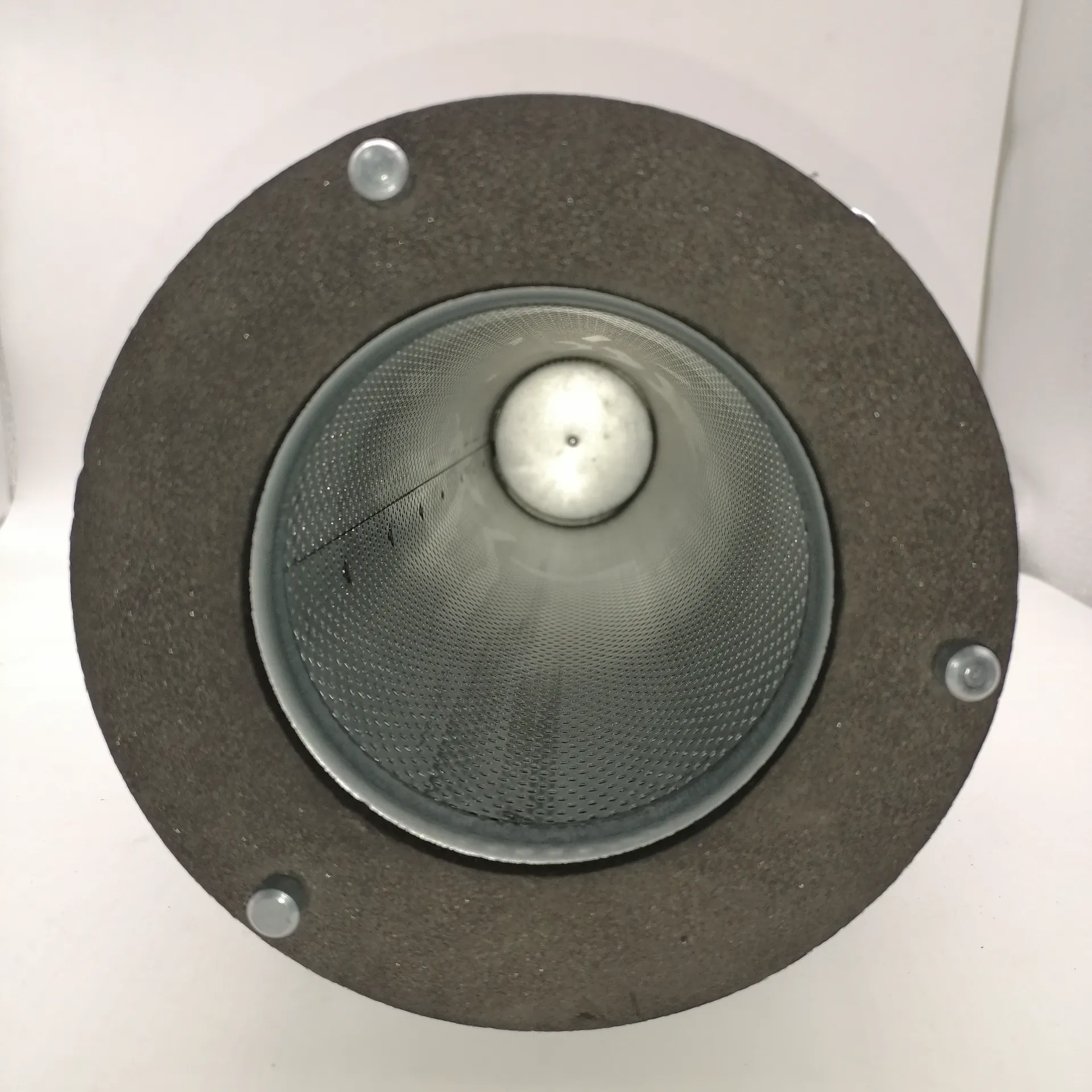

vacuum cartridge

Understanding Vacuum Cartridges Technology and Applications

In the realm of modern engineering and industrial applications, the vacuum cartridge stands out as an essential component in various systems, particularly in vacuum filtration and extraction technologies. This versatile device plays a crucial role in creating low-pressure environments necessary for numerous processes. This article explores the fundamentals of vacuum cartridges, their functionality, design considerations, and applications across different industries.

What is a Vacuum Cartridge?

A vacuum cartridge is a specialized device designed to operate under negative pressure, allowing the movement of fluids, gases, or particles. It functions by creating a vacuum that facilitates the removal of air or other undesirable gases from a sealed environment. This process helps enhance efficiency and effectiveness in various applications such as filtration, drying, and even in some manufacturing processes.

How Do Vacuum Cartridges Work?

The operation of a vacuum cartridge is relatively straightforward. It usually consists of an airtight casing that houses a filter element, which can be made from various materials depending on the application. When the system is activated, a vacuum pump removes air from the cartridge, generating a low-pressure area. This pressure differential drives the fluid or gas into the cartridge, where it can be filtered or collected.

The design of the vacuum cartridge can vary significantly based on its intended use. For instance, in a filtration application, the filter element may have specific pore sizes tailored to capture contaminants while allowing the desired fluid to pass through. The efficiency of this filtration process can be optimized through careful material selection and cartridge design.

Design Considerations

Several factors are crucial when designing a vacuum cartridge to ensure optimal performance

1. Material Selection The choice of materials is vital for the cartridge's durability and compatibility with the substances it will handle. Common materials include polymers, metals, and ceramics, each chosen for their unique properties.

2. Filtration Efficiency The performance of a vacuum cartridge is often measured by its filtration efficiency, defined by how effectively it captures contaminants while maintaining a high flow rate. This can be influenced by the pore size and structure of the filter media.

vacuum cartridge

3. Pressure Ratings It is essential to consider the operating pressure range of the vacuum cartridge. The design must withstand the extremes of both negative pressure and potentially high fluid flow rates without compromising integrity.

4. Maintenance and Replacement The ease of accessing the cartridge for maintenance or replacement is a significant design factor. Simplifying these processes can lead to decreased downtime in industrial applications.

Applications of Vacuum Cartridges

Vacuum cartridges find utility across a broad spectrum of industries, including

1. Chemical Processing In chemical production, vacuum cartridges are utilized for the efficient separation of solids from liquids, aiding in purifying chemicals and enhancing product quality.

2. Food and Beverage In the food industry, vacuum cartridges assist in processes like juice extraction and clarification, ensuring that the final products are free from impurities and maintain a high quality.

3. Pharmaceuticals The pharmaceutical sector leverages vacuum cartridges for sterilization and filtration, which are critical for ensuring that products are safe for consumption.

4. Environmental Applications Vacuum cartridges are also used in environmental monitoring and remediation efforts, helping to filter contaminants from water sources or air during pollution control processes.

5. Manufacturing In manufacturing, they support processes where dust control or material handling under reduced pressure is necessary, such as in powder handling systems.

Conclusion

Vacuum cartridges are indispensable tools in a multitude of applications, from supporting efficient industrial processes to playing a role in environmental protection. Their ability to create and maintain a vacuum allows for enhanced filtration, extraction, and separation processes, all critical in today's technologically driven world. Understanding their design, functionality, and varied applications helps to appreciate the profound impact they have on numerous industries, making them a crucial component in many operational systems. As technology continues to advance, so too will the designs and capabilities of vacuum cartridges, ensuring their continued relevance in the future of engineering and manufacturing.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: