ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 21, 2025 05:52 Back to list

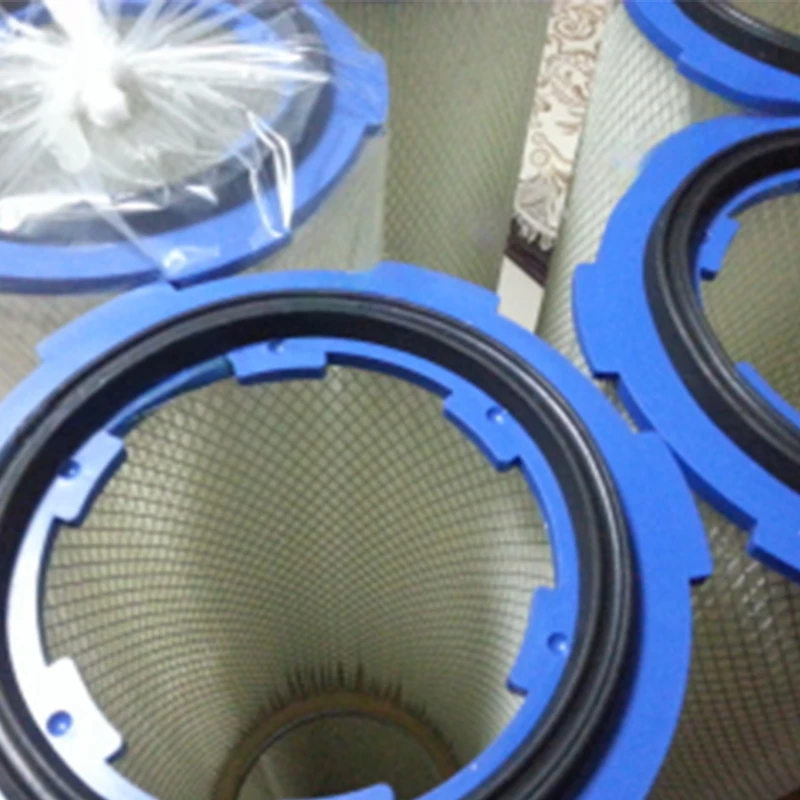

Factory good price anti static filter cartridge vacuum filter cartridge

Vacuum cartridges, often overshadowed by their more illustrious household counterparts, play a pivotal role across diverse industrial landscapes where precision and reliability are non-negotiable. In industries ranging from electronics manufacturing to pharmaceutical production, these unsung heroes ensure efficiency and efficacy, translating directly into operational success.

Moreover, as companies grapple with environmental responsibilities and sustainability metrics, vacuum cartridges contribute significantly to reducing energy consumption. Cartridges designed with energy efficiency in mind can lower operational energy requirements by optimizing flow paths and reducing air leaks. This not only decreases the carbon footprint but also provides tangible savings on energy costs, a crucial factor for operations looking to balance profitability with environmental stewardship. The credibility of a vacuum cartridge manufacturer also hinges on rigorous testing and the provision of certifications that assure clients of quality and safety standards. This is where authority in the field shines through. Reputable manufacturers will often possess ISO certifications and adhere to strict quality control standards, offering a layer of reassurance to their clients about the products they are investing in. Case studies and testimonials form a testament to the trustworthiness of a brand, echoing through expert reviews and historical performance records. As industries continue to innovate, staying informed about the latest advancements in vacuum cartridge technology becomes imperative. From enhancing pump efficiencies to integrating IoT capabilities for predictive maintenance, the future of vacuum cartridges is laden with transformative potential. For professionals in any industry reliant on these components, understanding the evolving landscape not only ensures alignment with technological advancements but also embeds their operations with reliability from the ground up. In conclusion, vacuum cartridges, while less conspicuous than their applications, are quintessential enablers of modern industrial processes. Their impact resonates through enhanced efficiency, reliability, and sustainability. From the microscopic precision required in technology manufacturing to the rigorous demands of food safety, vacuum cartridges stand as trusted pillars of excellence. Investing in quality cartridges designed with cutting-edge technology and backed by rigorous testing and certifications, is an investment in the very foundation of operational success and client trust across industry spectra.

Moreover, as companies grapple with environmental responsibilities and sustainability metrics, vacuum cartridges contribute significantly to reducing energy consumption. Cartridges designed with energy efficiency in mind can lower operational energy requirements by optimizing flow paths and reducing air leaks. This not only decreases the carbon footprint but also provides tangible savings on energy costs, a crucial factor for operations looking to balance profitability with environmental stewardship. The credibility of a vacuum cartridge manufacturer also hinges on rigorous testing and the provision of certifications that assure clients of quality and safety standards. This is where authority in the field shines through. Reputable manufacturers will often possess ISO certifications and adhere to strict quality control standards, offering a layer of reassurance to their clients about the products they are investing in. Case studies and testimonials form a testament to the trustworthiness of a brand, echoing through expert reviews and historical performance records. As industries continue to innovate, staying informed about the latest advancements in vacuum cartridge technology becomes imperative. From enhancing pump efficiencies to integrating IoT capabilities for predictive maintenance, the future of vacuum cartridges is laden with transformative potential. For professionals in any industry reliant on these components, understanding the evolving landscape not only ensures alignment with technological advancements but also embeds their operations with reliability from the ground up. In conclusion, vacuum cartridges, while less conspicuous than their applications, are quintessential enablers of modern industrial processes. Their impact resonates through enhanced efficiency, reliability, and sustainability. From the microscopic precision required in technology manufacturing to the rigorous demands of food safety, vacuum cartridges stand as trusted pillars of excellence. Investing in quality cartridges designed with cutting-edge technology and backed by rigorous testing and certifications, is an investment in the very foundation of operational success and client trust across industry spectra.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: