Tel:

+8615930870079

Tel:

+8615930870079

Aug . 07, 2024 19:25 Back to list

Understanding the Importance of Antistatic Filter Elements in Enhancing Industrial Equipment Performance

Understanding Antistatic Filter Elements Importance and Applications

In various industrial and commercial settings, the management of static electricity is crucial for ensuring safety, productivity, and the integrity of sensitive equipment. One often overlooked yet essential component in this regard is the antistatic filter element. This article explores the significance, functionality, and applications of antistatic filter elements, shedding light on why they are integral to modern industrial processes.

What Are Antistatic Filter Elements?

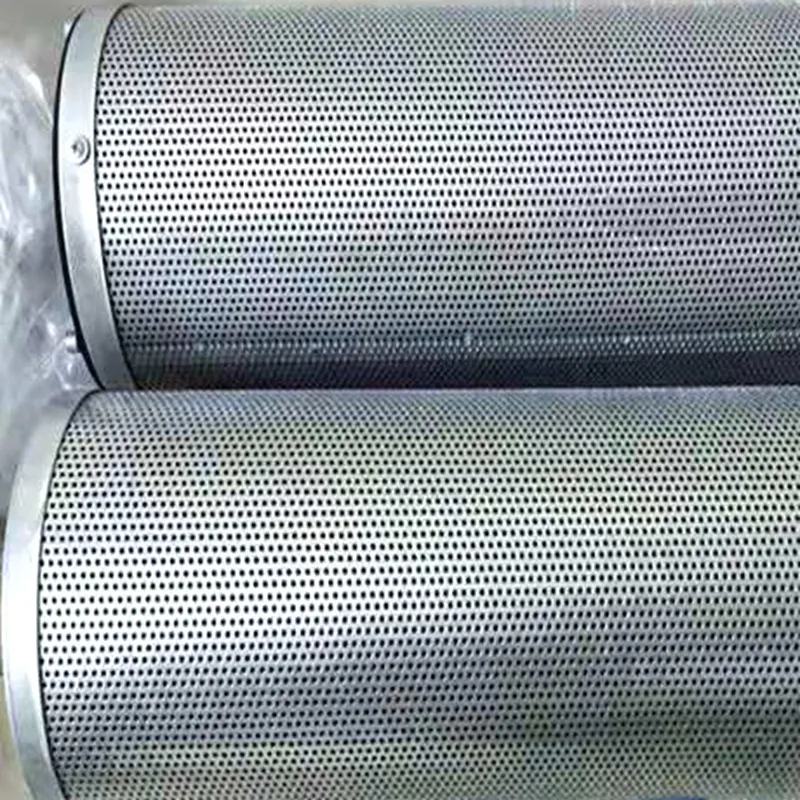

Antistatic filter elements are specialized filtration units designed to minimize the accumulation of static electricity, which can pose serious risks in environments where flammable substances or sensitive electronic components are present. These filter elements are typically made from materials treated with antistatic agents, which help to dissipate electrical charges that can build up during the filtration process.

The Importance of Antistatic Filter Elements

1. Safety Enhancement In industries where flammable gases, dust, or vapors are prevalent, static electricity can lead to catastrophic explosions or fires. Antistatic filter elements significantly reduce these risks by preventing the buildup of static charges, thereby promoting a safer working environment.

2. Protection of Equipment Sensitive electronic devices, such as computers and communication equipment, can suffer from electrostatic discharge (ESD), which can cause irreversible damage. By utilizing antistatic filter elements, businesses can protect their valuable equipment from unintended electrostatic surges, thus prolonging their lifecycle and reducing maintenance costs.

3. Improved Product Quality In manufacturing processes where particulate contamination can compromise the quality of products, antistatic filter elements help maintain a clean environment. By preventing static charge-induced dust attraction, these filters contribute to higher product standards and reduced defects.

4. Compliance with Regulations Many industries are governed by strict safety regulations regarding static electricity management. Using antistatic filter elements helps organizations comply with these regulations, avoiding potential fines and enhancing their reputation for safety and quality.

antistatic filter element

Applications of Antistatic Filter Elements

Antistatic filter elements find applications in various industries, including

- Electronics Manufacturing In the production of semiconductors and circuit boards, maintaining a static-free environment is critical. Antistatic filters are employed in cleanrooms and production lines to ensure that static charges do not compromise the integrity of components.

- Pharmaceuticals The pharmaceutical industry often deals with powders and granules that can generate static electricity. Antistatic filter elements are utilized in air handling systems to prevent contamination and ensure product consistency.

- Chemical Processing The chemical sector frequently encounters flammable substances. Employing antistatic filters in ventilation and exhaust systems mitigates the risk of static-induced explosions during chemical reactions or material handling.

- Food Industry Static electricity can attract dust and contaminants, impacting food safety. Antistatic filter elements help maintain a clean production environment in food processing facilities, ensuring compliance with health regulations.

Conclusion

In an era where industrial safety and product integrity are paramount, antistatic filter elements play a vital role in managing static electricity effectively. Their application across diverse industries highlights their versatility and necessity. As technology evolves and industries become more reliant on complex systems, the importance of incorporating antistatic measures, including the integration of antistatic filter elements, will continue to grow. Investing in these systems not only safeguards employees and equipment but also enhances overall operational efficiency and product quality.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: