Tel:

+8615930870079

Tel:

+8615930870079

Dec . 12, 2024 11:38 Back to list

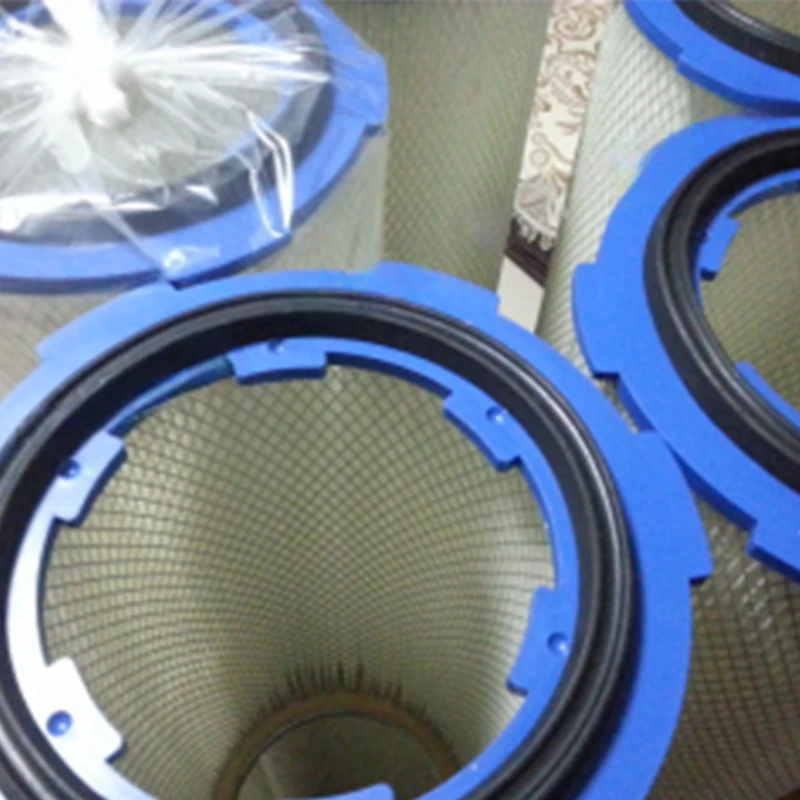

turbine air intake filters

The Importance of Turbine Air Intake Filters

Turbine air intake filters play a critical role in the operation and efficiency of gas turbines and jet engines. These filters are designed to protect the engine from particulate matter, foreign objects, and contaminants that may be present in the ambient air. As the demand for cleaner, more efficient energy in various industries continues to rise, the significance of high-quality air intake filtration systems cannot be overstated.

Functionality of Air Intake Filters

The primary function of turbine air intake filters is to ensure that the air entering the turbine is as clean as possible. Contaminants such as dust, dirt, pollen, and other particulates can significantly affect engine performance. If these particles are allowed to enter the turbine, they can cause numerous issues ranging from reduced efficiency to costly damage.

When the air passes through the filter, particulates are trapped within the filter media, allowing only clean air to reach the combustion chamber. This clean air is essential for optimal combustion, ensuring that the engine operates at its intended efficiency. Moreover, a well-maintained air intake filter system can lead to lower fuel consumption and reduced emissions, contributing to a more sustainable future.

Types of Air Intake Filters

There are several types of air intake filters used in turbine applications, each designed for specific operating conditions. The most common types include

1. Panel Filters These are flat filters used in many industrial applications due to their simple design and effectiveness. They are often pleated to increase surface area and improve filtration efficiency.

2. Bag Filters Bag filters have a larger surface area compared to panel filters and are often utilized in high-efficiency applications. They can capture finer particulates due to their greater depth.

3. Cyclone Separators These filters utilize centrifugal force to remove larger particles from the air before it reaches the main filtration system. They are often used as a pre-filter in conjunction with other filter types to extend their lifespan.

turbine air intake filters

4. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to capture at least 99.97% of particles that are 0.3 microns or larger. These filters are often used in sensitive applications where the highest levels of cleanliness are required.

Maintenance and Replacement

Regular maintenance and timely replacement of turbine air intake filters are essential for ensuring optimal engine performance. Dirty or clogged filters can lead to increased pressure drop, which requires the engine to work harder, thereby decreasing fuel efficiency and increasing wear and tear on engine components.

Scheduled inspections should include checking the condition of filters, identifying any signs of damage or excessive dirt accumulation, and ensuring that the filters are replaced as needed. Developing a maintenance schedule based on the operating environment and the manufacturer's recommendations can significantly enhance the longevity of the filtration system.

The Impact of Technology

Advancements in technology have led to the development of more efficient air intake filters. Modern filters use advanced materials and structures that improve filtration efficiency while minimizing airflow resistance. For instance, nanofiber technology enables filters to capture smaller particles without significantly increasing the pressure drop.

Moreover, some air intake systems are now equipped with monitoring systems that can provide real-time data on filter performance. This technology allows for predictive maintenance, helping operators to replace filters before they reach a contaminant saturation point.

Conclusion

In summary, turbine air intake filters are vital components that contribute to the efficiency and longevity of gas turbines and jet engines. With advancements in filter design and monitoring technology, operators can ensure that their engines receive the cleanest air possible, thereby maximizing performance and minimizing environmental impact. Investing in high-quality filtration systems and adhering to a solid maintenance schedule can lead to significant operational benefits, including reduced fuel costs, lower emissions, and extended equipment life. As the energy landscape continues to evolve, the role of air intake filters will remain crucial in supporting cleaner and more efficient energy production.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: