Tel:

+8618931101301

Tel:

+8618931101301

Nov . 08, 2024 21:15 Back to list

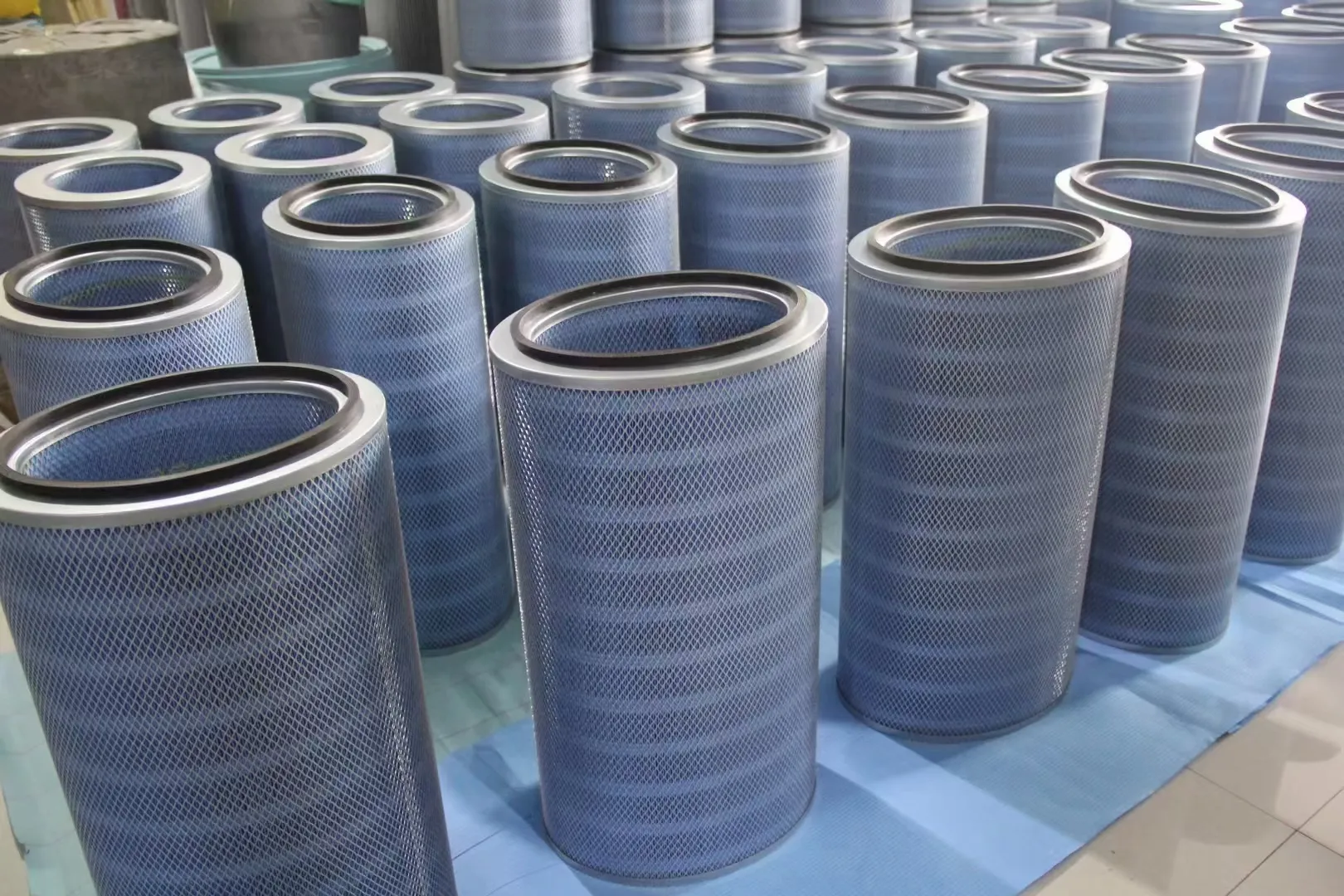

turbine air intake filters

The Importance of Turbine Air Intake Filters

In the realm of aviation and industrial applications, turbine engines play a crucial role in ensuring efficiency and performance. One of the most vital components of these engines is the air intake filter. Maintaining clean and efficient air intake is essential for optimal engine performance, and air intake filters are designed to fulfill that role.

Function of Air Intake Filters

Turbine air intake filters serve as a barrier between the external environment and the sensitive components within the engine. They are responsible for trapping particulate matter, dirt, debris, and other contaminants that could potentially damage the engine. By filtering the air before it enters the combustion chamber, these filters help in maintaining the engine's efficiency, reliability, and longevity.

Air quality is vital for turbine engines; contaminated air can lead to combustion issues, decreased performance, and could even cause catastrophic failures. By using high-quality filters, operators can ensure that the turbines operate at their best, with reduced wear and tear on engine components.

Types of Air Intake Filters

There are several types of air intake filters used in turbine engines, each designed for specific applications

. The most common types include1. Dry Filters These are made from synthetic materials that provide excellent filtration without adding significant weight to the system. Dry filters are often used in commercial aviation due to their efficiency and ease of maintenance.

2. Oil-Wetted Filters These filters are coated with a thin layer of oil, which captures airborne particles as they pass through. Oil-wetted filters are reusable and can be cleaned and re-oiled, making them a cost-effective choice for many industrial applications.

turbine air intake filters

3. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are designed to trap particles as small as 0.3 microns. They are commonly used in settings where the highest level of air cleanliness is required, such as in hospitals or cleanrooms.

4. Pre-Filters These are often used in conjunction with primary filters to extend their life by capturing larger particles before they reach the main filter. This multi-stage approach can enhance overall filtration efficiency.

Maintenance and Replacement

Regular maintenance of turbine air intake filters is crucial for ensuring optimal engine performance. Filters should be inspected frequently, and the replacement schedule should be based on manufacturer recommendations or operational conditions.

Failing to replace a clogged or damaged filter can lead to reduced airflow, causing the engine to work harder and consume more fuel. Additionally, increased contaminant levels can lead to greater wear on engine components, ultimately resulting in more costly repairs.

The Future of Air Intake Filtration

As technology evolves, so does the development of air intake filters. Innovations in materials and design are leading to more efficient filters that can capture a wider range of particulates while maintaining air flow. With the rising awareness of environmental issues, manufacturers are also focusing on creating filters that are more sustainable and easier to recycle.

In conclusion, turbine air intake filters are an essential component in safeguarding the performance and longevity of engines. By understanding their importance, types, and maintenance needs, operators can enhance the efficiency of their systems and reduce operational costs. As technology continues to advance, we can expect even more improvements in filtration solutions, ensuring that turbine engines remain a reliable choice for the future.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: