ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 14, 2025 11:19 Back to list

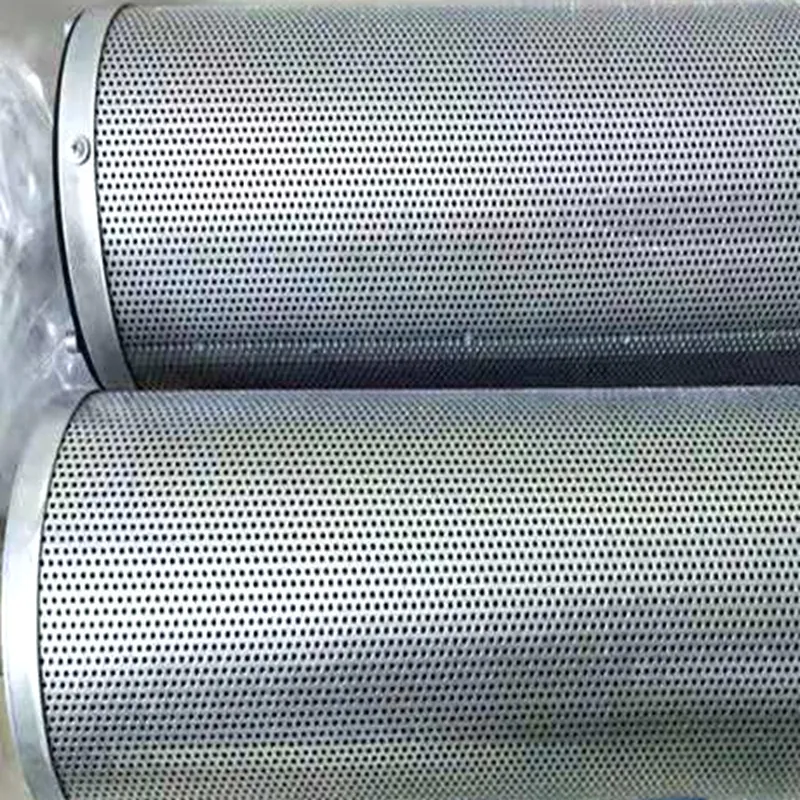

stainless steel filter element

The stainless steel filter element is an integral component in numerous industrial and commercial applications, offering unparalleled durability and performance. As someone who has extensively worked with filtration systems, the advantages of utilizing stainless steel filter elements are clear and multifaceted. Their robust nature and capacity to withstand extreme conditions make them indispensable for industries ranging from oil and gas to pharmaceuticals.

From an experience perspective, leveraging stainless steel filter elements can profoundly impact operational success. Companies utilizing these filters report reduced downtime and fewer filter replacements. This operational efficiency translates into substantial cost savings and improved bottom-line performance, emphasizing why investing in high-quality filtration solutions is prudent for sustained industrial success. To optimize their application, it is crucial to consider the specific filtration requirements and select appropriately sized elements that align with operational demands. Proper installation and maintenance further enhance the efficacy of these elements, ensuring they perform optimally over their lifecycle. In conclusion, stainless steel filter elements are more than just components—they are vital to maintaining the integrity of processes across diverse industries. As subject matter experts continue to explore newer applications, the standing of these filter elements will only grow, reinforcing their status as a cornerstone of effective filtration solutions.

From an experience perspective, leveraging stainless steel filter elements can profoundly impact operational success. Companies utilizing these filters report reduced downtime and fewer filter replacements. This operational efficiency translates into substantial cost savings and improved bottom-line performance, emphasizing why investing in high-quality filtration solutions is prudent for sustained industrial success. To optimize their application, it is crucial to consider the specific filtration requirements and select appropriately sized elements that align with operational demands. Proper installation and maintenance further enhance the efficacy of these elements, ensuring they perform optimally over their lifecycle. In conclusion, stainless steel filter elements are more than just components—they are vital to maintaining the integrity of processes across diverse industries. As subject matter experts continue to explore newer applications, the standing of these filter elements will only grow, reinforcing their status as a cornerstone of effective filtration solutions.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: