Tel:

+8615930870079

Tel:

+8615930870079

Nov . 22, 2024 11:44 Back to list

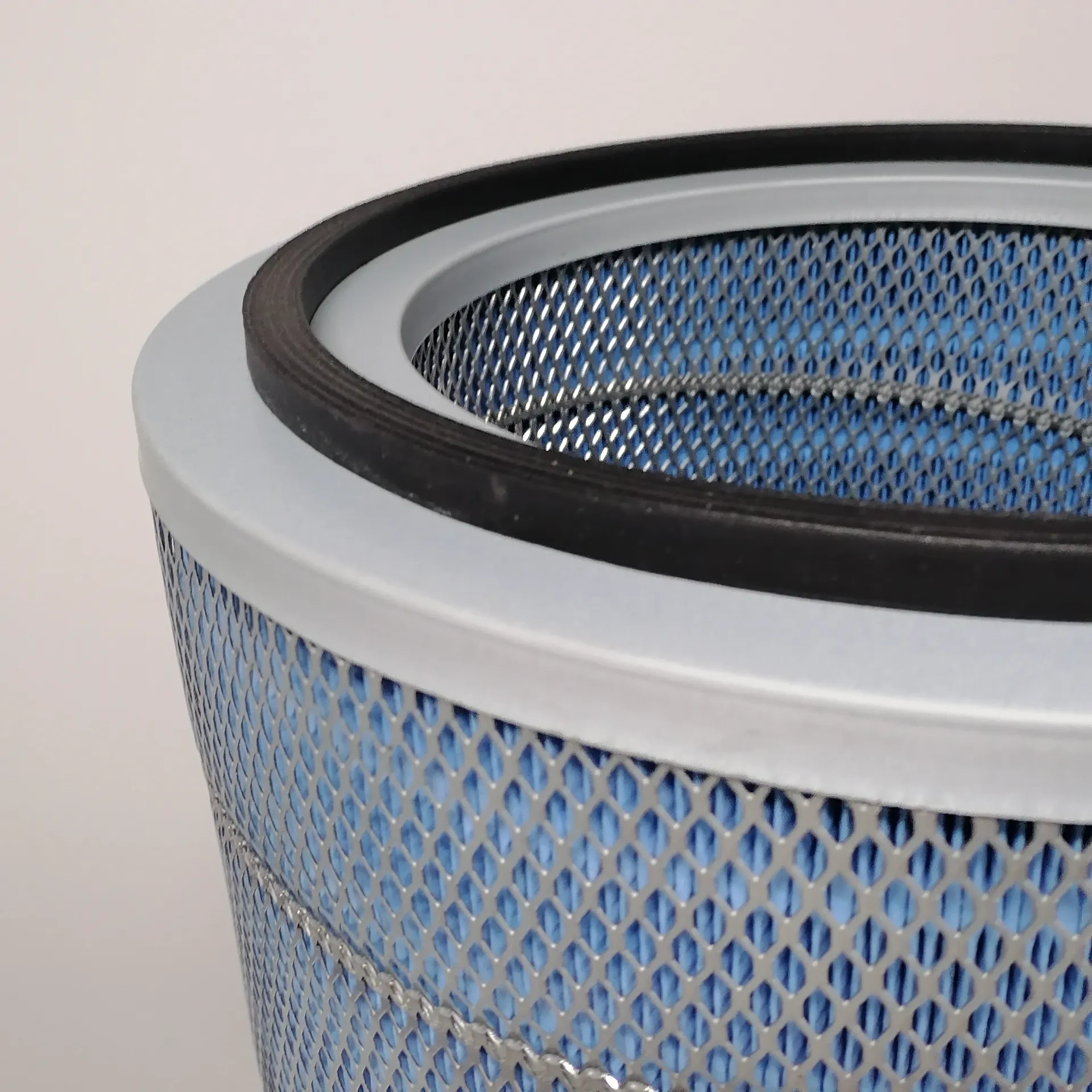

stainless filter cartridge

The Essential Guide to Stainless Steel Filter Cartridges

Stainless steel filter cartridges are pivotal components in various filtration systems, known for their durability, efficiency, and versatile applications. As industries increasingly prioritize quality and performance, these filters have emerged as a popular choice for numerous processes where purity and reliability are essential.

What Are Stainless Steel Filter Cartridges?

Stainless steel filter cartridges are cylindrical filtration devices made from high-grade stainless steel. They are designed to capture and remove particles, impurities, and contaminants from liquids and gases in various applications. Unlike traditional filters made from paper or plastic, stainless steel cartridges offer superior strength and longevity, making them suitable for demanding environments.

Advantages of Stainless Steel Filter Cartridges

1. Durability One of the primary benefits of stainless steel filter cartridges is their durability. Stainless steel is resistant to corrosion and rust, making these cartridges ideal for use in harsh chemical environments. This longevity translates into lower replacement costs and reduced downtime.

2. High Flow Rates Stainless steel filters can accommodate high flow rates due to their structural integrity and design. This capability allows for efficient filtration without compromising the system's overall performance, making them particularly useful in industries such as manufacturing and pharmaceuticals.

3. Temperature and Pressure Resistance Stainless steel filters can withstand extreme temperatures and pressures, setting them apart from other filter materials. This flexibility enables their use in diverse applications, from hot liquid filtration to high-pressure gas filtering.

stainless filter cartridge

4. Reusability Many stainless steel filter cartridges are designed for cleaning and reuse. This feature not only enhances their sustainability but also significantly reduces waste and operating costs. Users can easily clean the cartridges using backwashing or chemical cleaning methods, allowing for prolonged service life.

5. Versatile Applications These filter cartridges find use in a myriad of industries, including food and beverage, pharmaceuticals, petrochemicals, water treatment, and microelectronics. Their adaptability ensures that they meet varying filtration requirements and performance standards.

Maintenance and Care

Proper maintenance of stainless steel filter cartridges is crucial for optimal performance. Routine inspections should be conducted to check for signs of wear and tear. Cleaning intervals depend on the specific application and the level of contamination in the filtered media. Users should follow manufacturer guidelines for cleaning procedures to avoid damaging the filter structure.

Environmental Impact

In an era emphasizing sustainability, stainless steel filter cartridges stand out due to their eco-friendly characteristics. Their longevity reduces the frequency of replacements, leading to decreased waste generation. Additionally, being made of recyclable materials, these cartridges can contribute to a circular economy by minimizing their environmental footprint.

Conclusion

Stainless steel filter cartridges represent a robust solution for filtration needs across various industries. Their combination of durability, efficiency, and versatility makes them an attractive option for businesses seeking reliable filtration solutions. As technology advances and industries evolve, the role of stainless steel filter cartridges will continue to be pivotal in ensuring product quality and safety. Investing in these high-performance filters can yield significant long-term benefits, enhancing operational efficiency while minimizing environmental impact. With the right maintenance and care, stainless steel filter cartridges can effectively serve any filtration requirement, solidifying their place in modern industrial applications.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: