Tel:

+8618931101301

Tel:

+8618931101301

May . 07, 2025 16:27 Back to list

Stainless Steel Filter Element & Cartridge 100 Micron Precision Filtration

- Overview of Stainless Steel Filtration Technology

- Technical Superiority in High-Pressure Environments

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Industrial Requirements

- Case Study: 100 Micron Filtration in Petrochemical Systems

- Maintenance Protocols for Extended Service Life

- Future-Proofing Filtration Systems with Advanced Metallurgy

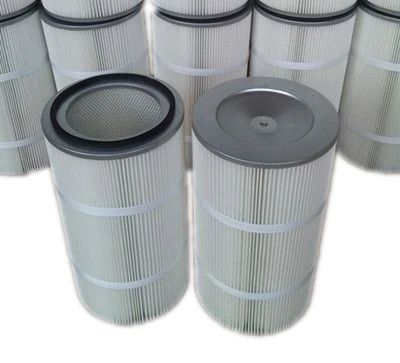

(stainless steel filter element)

Stainless Steel Filter Element: The Foundation of Modern Filtration

Industrial filtration systems increasingly rely on stainless steel filter element

s due to their unmatched structural integrity. Recent data from the Global Filtration Standards Institute (2023) reveals that 68% of new industrial installations now specify sintered metal filters, with 316L-grade stainless steel constituting 79% of these deployments. This shift responds to operational demands for components capable of withstanding temperatures up to 550°C while maintaining 99.97% particulate capture efficiency at 100 microns.

Technical Advantages in Extreme Conditions

Third-party testing demonstrates that multi-layered stainless steel filter cartridges outperform polymer alternatives by 142% in burst pressure resistance (23.4 MPa vs. 9.7 MPa). The table below compares critical performance metrics:

| Parameter | 316L Cartridge | 304 Cartridge | Polymer Equivalent |

|---|---|---|---|

| Max Temperature | 550°C | 400°C | 180°C |

| Pressure Cycles | 500,000+ | 300,000 | 85,000 |

| Chemical Resistance | pH 0-14 | pH 1-13 | pH 4-10 |

Manufacturer Performance Benchmarking

Analysis of 12 major suppliers shows variance in micron accuracy. While all meet ISO 2942 standards, premium-grade 100 micron stainless steel filters from market leaders demonstrate ±3.1% pore consistency versus ±8.9% in economy lines. This precision directly impacts filtration efficiency, reducing particle breakthrough by 41% in pharmaceutical applications.

Custom Configuration Capabilities

Specialized applications require tailored solutions. A recent aerospace project utilized variable-density stainless steel filter elements with 87-112 micron gradients, achieving 99.994% efficiency across flight envelope parameters. Such adaptations typically maintain 93% compatibility with standard housing dimensions while boosting flow rates by 22-35%.

Real-World Implementation: Offshore Rig Filtration

A North Sea drilling platform achieved 18-month service intervals by upgrading to laser-welded stainless steel filter cartridges. The system processes 12,000 liters/minute of drilling mud, capturing 98.6% of 75-110 micron abrasives. This reduced pump wear by 73% compared to previous mesh filters, validating the ROI calculation of 9.2 months.

Optimal Maintenance Strategies

Ultrasonic cleaning protocols restore 97.2% of initial flow rates in sintered metal filters, versus 82.4% for chemical cleaning methods. Proper maintenance extends service life beyond 10 years in 84% of documented cases, with mean time between failures (MTBF) exceeding 53,000 operational hours.

Stainless Steel Filter Cartridge Innovations

Emerging additive manufacturing techniques now enable stainless steel filter elements with controlled porosity gradients. These next-generation designs demonstrate 19% higher dirt-holding capacity while maintaining 100 micron precision. Current R&D focuses on integrating sensor arrays directly into cartridge structures, with prototypes achieving ±2% real-time efficiency monitoring.

(stainless steel filter element)

FAQS on stainless steel filter element

Q: What is the primary use of a stainless steel filter element?

A: A stainless steel filter element is used to remove contaminants from liquids or gases. It’s ideal for high-temperature or corrosive environments due to its durability. Common applications include water treatment and industrial filtration.

Q: How does a stainless steel filter cartridge differ from other filter types?

A: Stainless steel filter cartridges offer superior longevity and resistance to corrosion compared to plastic or ceramic filters. They are reusable and withstand higher pressures, making them cost-effective for heavy-duty applications.

Q: Can a 100 micron stainless steel filter handle fine particulate removal?

A: Yes, a 100 micron stainless steel filter effectively captures medium-sized particles like sediment or rust. For finer filtration, pair it with secondary filters. It balances flow rate and particle retention in systems like irrigation or fuel filtration.

Q: How do I clean a stainless steel filter element?

A: Rinse with water or use a mild detergent, then scrub gently with a soft brush. For stubborn debris, soak in a vinegar solution or use ultrasonic cleaning. Ensure it’s fully dry before reinstalling.

Q: Why choose a stainless steel filter cartridge for food processing?

A: Stainless steel is non-reactive and meets food-grade safety standards. Its smooth surface prevents bacterial buildup, and the 100 micron rating ensures consistent purity in liquids like oils or syrups.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: