Tel:

+8615930870079

Tel:

+8615930870079

Dec . 05, 2024 15:07 Back to list

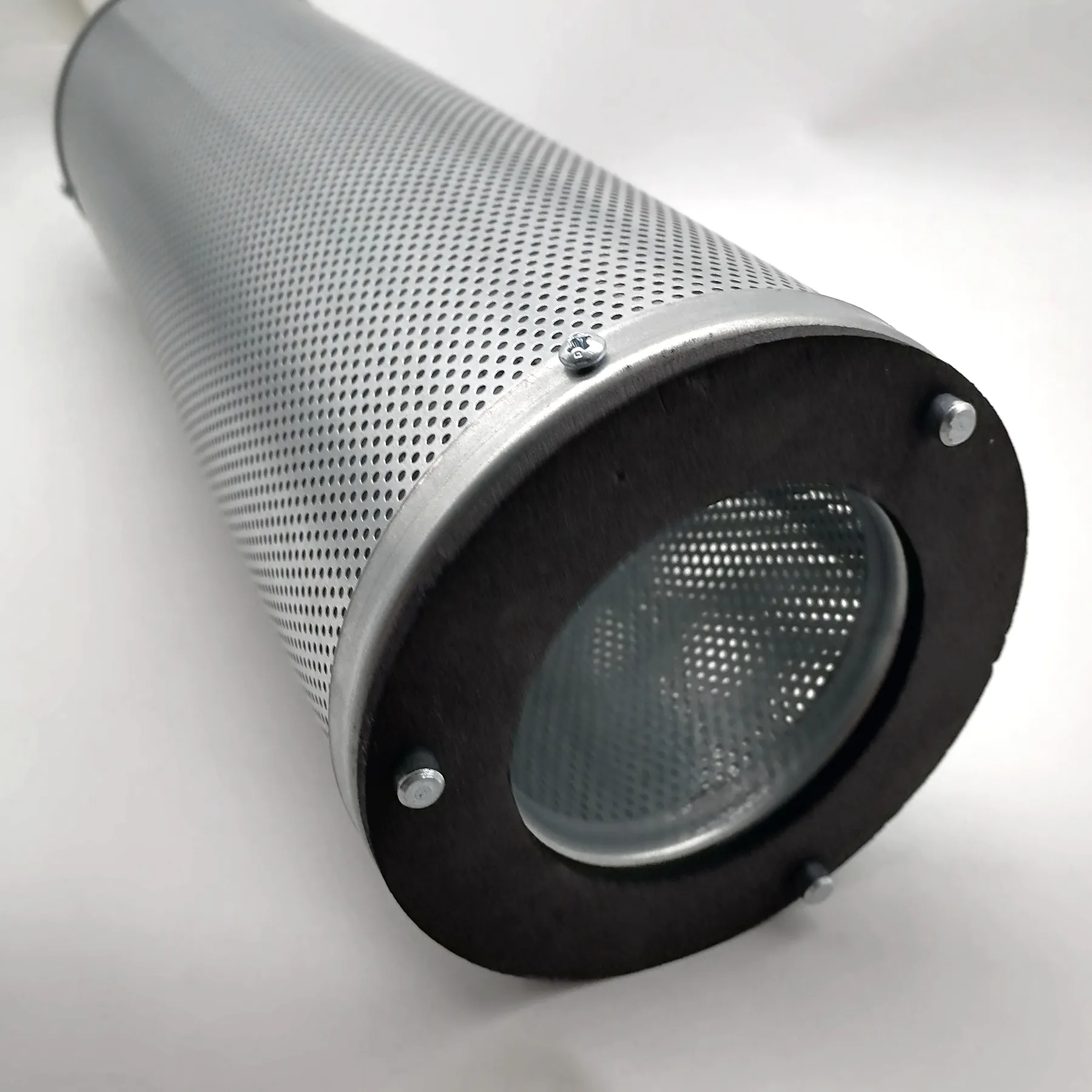

ss sintered filter cartridge

Understanding SS Sintered Filter Cartridges

In the realm of filtration technology, stainless steel (SS) sintered filter cartridges have emerged as a staple solution across various industries. These innovative components are designed for efficient filtration processes, offering durability, reliability, and exceptional performance. To fully understand their significance and utility, it’s vital to delve into what sintered filters are, how they work, their applications, and the advantages they offer.

What is a Sintered Filter Cartridge?

A sintered filter cartridge is a type of porous filter made from stainless steel that is manufactured through a process called sintering. Sintering involves compacting and heating powdered metal particles to form a solid piece without completely melting the materials. This technique creates a fine, porous structure, allowing for excellent filtration properties while maintaining the integrity and strength of stainless steel.

Sintered filter cartridges can be designed in various porosities and micron ratings, catering to different filtration needs. The manufacturing process often allows for customization in terms of dimensions, shapes, and filter ratings, making them versatile for numerous applications.

How Do SS Sintered Filters Work?

The operation of SS sintered filter cartridges is based on the principle of size exclusion and depth filtration. As fluid passes through the filter, larger particles are trapped on the surface or within the pores of the sintered material, while smaller particles and liquid flow through. This multilayer structure not only enhances the effectiveness of the filtration process but also prolongs the lifespan of the filter as it can collect a significant amount of contaminants without clogging quickly.

The robust nature of stainless steel ensures that sintered filters can withstand varying temperatures and pressures, making them suitable for different operational environments. They are particularly effective in filtering liquids and gases in both industrial and laboratory settings.

Applications of SS Sintered Filters

SS sintered filter cartridges find applications across a multitude of industries

ss sintered filter cartridge

1. Chemical Processing In chemical manufacturing, these filters are utilized to remove impurities from raw materials, ensuring product purity and quality. 2. Food and Beverage The food industry employs sintered filters to refine liquids, such as oils and juices, to enhance clarity and remove unwanted particles. 3. Pharmaceuticals In the pharmaceutical sector, ensuring sterility and purity in drug production is essential. SS sintered filters excel in this regard by effectively filtering out bacteria and other contaminants. 4. Oil and Gas These filters are widely used in the oil and gas industry for separating solids and particulates from fluids, safeguarding equipment and optimizing operations. 5. Water Treatment Sintered filters play a crucial role in water and wastewater treatment processes, helping to ensure clean and safe water supply.

Advantages of SS Sintered Filters

The benefits of using SS sintered filter cartridges are numerous

- Durability Made from stainless steel, these filters boast exceptional resistance to corrosion and high temperatures. Their durability translates to a longer operational life compared to conventional filters.

- Reusability Unlike disposable filters, sintered filters can often be cleaned and reused, further reducing operational costs and waste.

- High Filtration Efficiency With their ability to filter particles down to very small sizes (often sub-micron), they provide high filtration efficiency, essential for critical applications.

- Customizability Manufacturers can produce sintered filter cartridges tailored to specific filtration needs, making them versatile for various applications.

- Environmentally Friendly Their reusable nature and long lifespan contribute to reducing the environmental impact associated with disposable filtration products.

Conclusion

In conclusion, SS sintered filter cartridges represent a significant advancement in filtration technology, combining the durability of stainless steel with the efficacy of sintered filtration. Their diverse applications across numerous industries underscore their importance and adaptability. As industries strive for greater efficiency and environmental responsibility, the role of sintered filters will likely continue to grow, making them a valuable asset in modern filtration solutions. Whether for chemical processing, water treatment, or any other application, understanding the capabilities of SS sintered filter cartridges is essential for optimizing filtration processes and ensuring product quality.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: