Tel:

+8615930870079

Tel:

+8615930870079

Nov . 15, 2024 19:46 Back to list

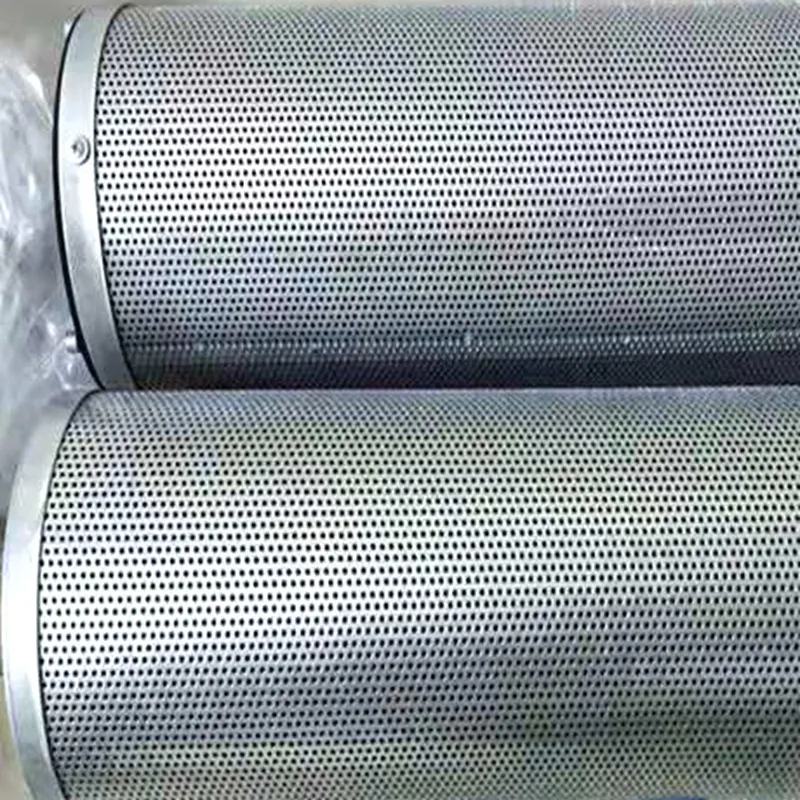

ss sintered filter cartridge

Understanding SS Sintered Filter Cartridges A Comprehensive Guide

When it comes to filtration technology, SS sintered filter cartridges have emerged as one of the most efficient and reliable options. These cartridges, made from stainless steel, are increasingly popular across various industries due to their robust nature and exceptional filtering capabilities. This article delves into the intricacies of SS sintered filter cartridges, exploring their construction, applications, advantages, and maintenance.

What are SS Sintered Filter Cartridges?

SS sintered filter cartridges are filtration devices made from stainless steel that utilize a sintering process to create a porous structure. During this process, stainless steel powder is heated and compacted, resulting in a solid material with interconnected pores. This unique structure allows the cartridges to provide superior durability and resistance to harsh environments, making them ideal for demanding filtration requirements.

Applications of SS Sintered Filter Cartridges

These filter cartridges are widely used in various industries, including

1. Chemical Processing SS sintered filters are ideal for removing contaminants from chemicals and solvents, ensuring that the final products meet stringent purity standards.

2. Pharmaceutical Production In the pharmaceutical industry, maintaining sterile conditions is paramount. SS sintered filter cartridges help maintain the integrity of pharmaceutical processes by filtering out particulates and bacteria.

3. Food and Beverage Industry Ensuring food safety is critical in the food supply chain. SS sintered filters are used to clarify liquids and remove impurities, contributing to quality control in food processing.

4. Oil and Gas These cartridges are employed for filtration in various oil and gas applications, providing robust performance under high pressure and temperature conditions.

ss sintered filter cartridge

Advantages of SS Sintered Filter Cartridges

1. Durability Unlike traditional polymer filters, SS sintered cartridges can withstand extreme temperatures and pressures, enhancing their longevity in industrial applications.

2. Chemical Resistance Stainless steel is highly resistant to corrosion and degradation, making these cartridges suitable for filtering aggressive chemicals and harsh solvents.

3. Easy Cleaning and Reusability SS sintered filters can be cleaned and reused multiple times, reducing waste and offering a cost-effective solution for long-term filtration needs.

4. Precision Filtration With a variety of pore sizes available, these cartridges can achieve precise filtration, catering to different requirements, from coarse to fine filtration.

5. Sustainability The use of stainless steel makes these cartridges environmentally friendly. They are recyclable and help reduce the need for disposable filters, contributing to a more sustainable filtration solution.

Maintenance of SS Sintered Filter Cartridges

To ensure optimal performance and extend the lifespan of SS sintered filter cartridges, routine maintenance is essential. Regular cleaning can be done using various methods, such as backwashing or ultrasonic cleaning, depending on the application and the type of contaminants being filtered. Inspecting the cartridges for any signs of wear or damage is also crucial to avoid operational failures.

Conclusion

In conclusion, SS sintered filter cartridges offer a robust, efficient, and environmentally friendly solution for various filtration challenges across multiple industries. Their durability, chemical resistance, and easy maintenance make them a preferred choice for applications requiring high performance and reliability. As industries continue to evolve and demand stricter quality standards, the relevance of SS sintered filter cartridges will likely increase, paving the way for more innovative filtration solutions in the future. By understanding their capabilities and proper maintenance practices, industries can maximize the benefits of these advanced filtration systems.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: