Tel:

+8615930870079

Tel:

+8615930870079

Nov . 11, 2024 11:40 Back to list

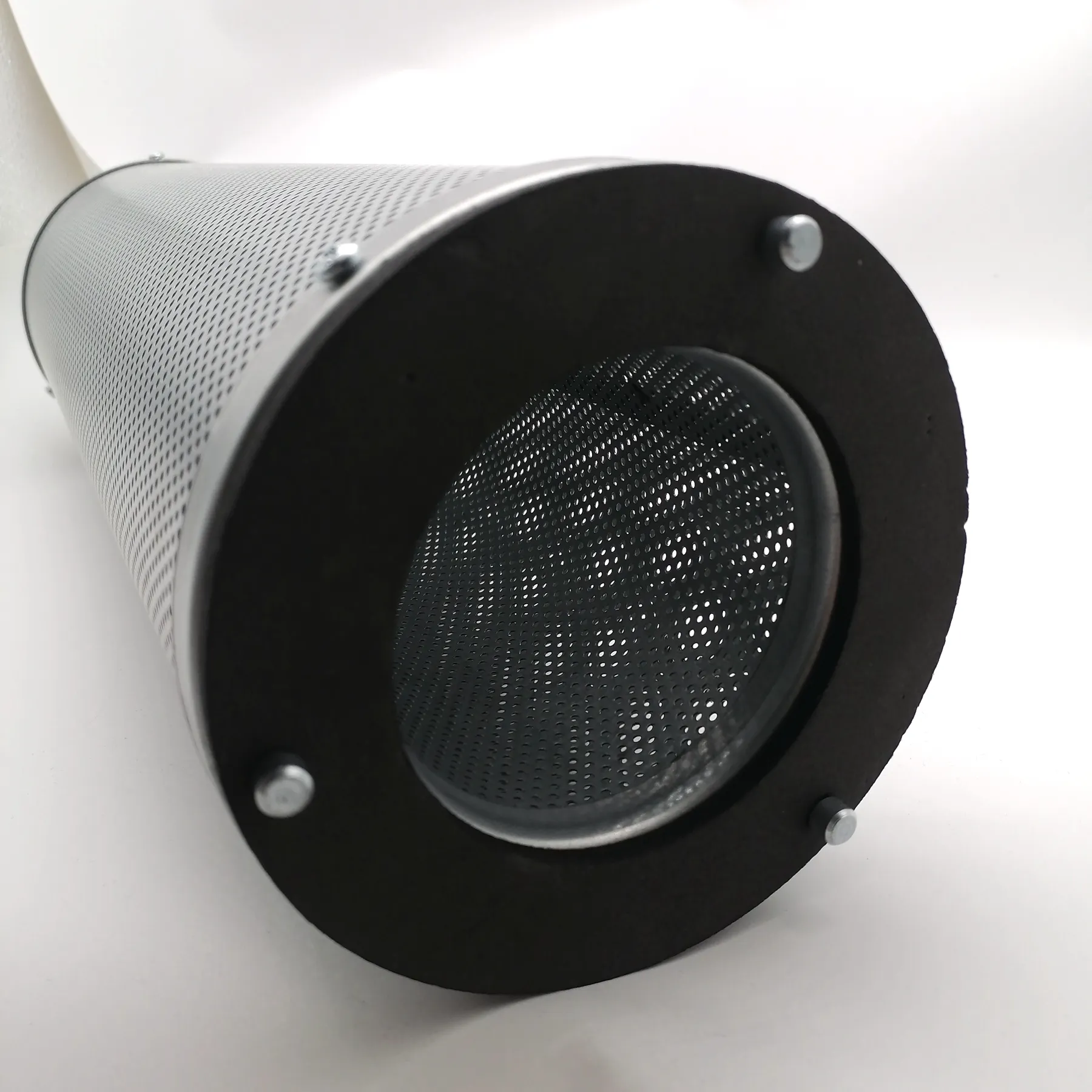

ss sintered filter cartridge

The Importance of SS Sintered Filter Cartridges in Industrial Applications

In the realm of industrial filtration, the SS (stainless steel) sintered filter cartridge has emerged as a vital component for various applications. Known for its durability, efficiency, and versatility, this type of filtration solution plays a significant role in maintaining the quality of fluids in diverse industries, including pharmaceuticals, food and beverage, chemicals, and water treatment.

What is a Sintered Filter Cartridge?

A sintered filter cartridge is a filtration device made from porous materials that are created through the process of sintering. In this process, stainless steel powder is compacted and heated to a temperature that allows the particles to fuse together, without liquefying. This results in a strong, porous structure that can effectively filter particles from liquids and gases. The pores created during this process can be precisely controlled, allowing manufacturers to create filters that can capture specific particle sizes, which is critical for effective filtration.

Key Advantages of SS Sintered Filter Cartridges

1. Chemical Resistance Stainless steel is inherently resistant to corrosion and can withstand harsh chemicals. This property makes SS sintered filter cartridges ideal for applications in industries that handle aggressive substances, such as petrochemicals and pharmaceuticals.

2. Durability and Longevity The robust design of sintered filter cartridges ensures a longer lifespan compared to traditional filters. They can endure high temperatures and pressures, making them suitable for demanding environments.

3. Easy Cleaning and Maintenance One of the standout features of SS sintered filters is their ability to be cleaned and reused. This not only reduces waste but also provides a cost-effective solution in situations where filters would otherwise need to be discarded.

ss sintered filter cartridge

4. High Filtration Efficiency SS sintered filter cartridges offer exceptional filtration performance, often achieving high retention rates for particulates. This capability ensures that the final products in processes are free from contaminants, maintaining product quality and compliance with industry standards.

5. Versatility These filter cartridges can be used in various forms of filtration, including liquid filtration, gas filtration, and even as pre-filters in more complex systems. Their adaptability allows industries to implement them in a myriad of processes.

Applications of SS Sintered Filter Cartridges

The applications of SS sintered filter cartridges are vast and diverse. In the pharmaceutical industry, they are used to ensure that solvents and solutions are free from particulate contamination, which is essential for compliance with health regulations. In the food and beverage sector, these filters help maintain product purity by filtering out impurities during production processes.

In chemical processing, SS sintered filters are utilized to separate particulates from various reactions and to ensure the cleanliness of chemical products. Additionally, they are integral to water treatment facilities, where they play a crucial role in removing sediments and ensuring the safety of drinking water.

Conclusion

SS sintered filter cartridges are indispensable in modern industrial applications. Their combination of durability, chemical resistance, and high filtration efficiency makes them a preferred choice for companies looking to enhance their filtration processes. As industries continue to face increasing demands for quality and compliance, the role of SS sintered filter cartridges will likely expand, cementing their place as a cornerstone of effective filtration systems. Investing in these cartridges is not just about meeting current needs; it is a strategic move towards sustainability and operational efficiency in the long run. By choosing SS sintered filters, industries can ensure that they are equipped with the best possible tools to tackle the challenges of filtration today and into the future.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: