Tel:

+8615930870079

Tel:

+8615930870079

Oct . 14, 2024 03:59 Back to list

ss sintered filter cartridge

The Advantages of SS Sintered Filter Cartridges

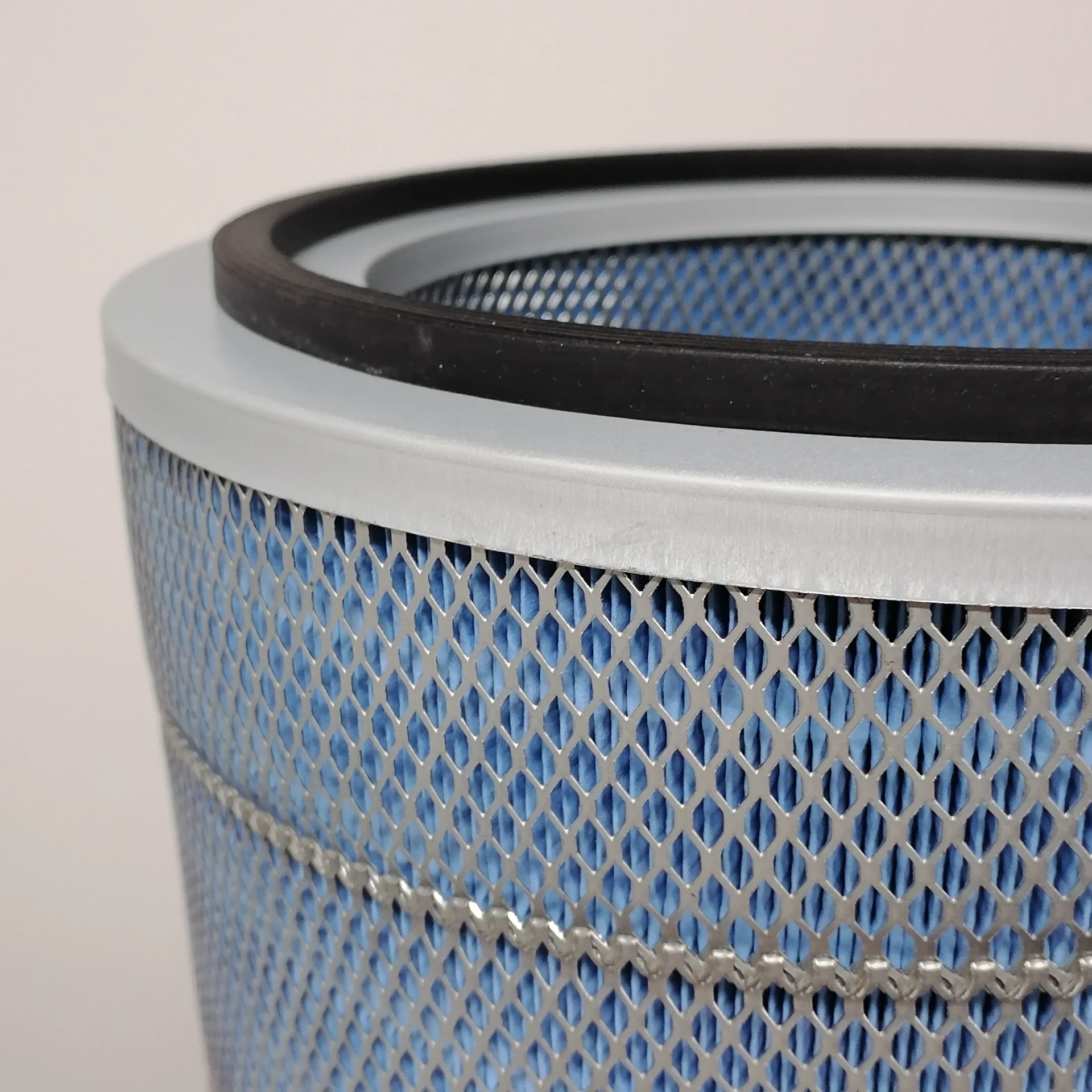

In the realm of filtration technology, the significance of selecting the right filter media cannot be overstated. Among the various options available in the market, stainless steel (SS) sintered filter cartridges have emerged as a versatile and durable solution for numerous industrial applications. These cartridges are renowned for their superior performance, resilience, and long service life, making them an ideal choice for various fluid filtration processes.

What Are SS Sintered Filter Cartridges?

SS sintered filter cartridges are designed using a process known as sintering, in which stainless steel powder is heated to a point where it fuses together without actually melting. This results in a porous structure with a consistent pore size, allowing for effective separation of particulates from fluids. The filtration mechanism of these cartridges primarily relies on depth filtration, which ensures that contaminants are trapped throughout the thickness of the filter media rather than just on the surface.

Key Advantages

1. Durability and Longevity One of the most significant advantages of SS sintered filter cartridges is their durability. Made from high-quality stainless steel, these filters can withstand harsh chemicals, extreme temperatures, and high-pressure environments. This resilience translates to a longer lifespan compared to traditional filters, reducing the need for frequent replacements.

2. High Filtration Efficiency The sintering process creates a homogeneous structure with controlled pore sizes, allowing for consistent filtration performance. SS sintered filter cartridges can efficiently remove particles ranging from micron to sub-micron sizes. This high filtration efficiency is crucial in industries like pharmaceuticals, food and beverage, and oil and gas, where product purity is paramount.

ss sintered filter cartridge

3. Easy Cleaning and Reusability Unlike disposable filters, stainless steel sintered cartridges can be easily cleaned and reused multiple times. They can tolerate backwashing, which involves reversing the flow of the fluid to dislodge trapped particles. This reusability not only reduces waste but also lowers operational costs over time.

4. Wide Application Range SS sintered filters are versatile and can be utilized in various applications, including liquid filtration, gas filtration, and even catalytic processes. They are widely used in industries such as petrochemicals, water treatment, metalworking, and electronics due to their adaptability and effectiveness.

5. Environmental Benefits By opting for reusable SS sintered filters, companies can significantly reduce their environmental footprint. The decreasing reliance on single-use filters contributes to less waste generation and a more sustainable approach to filtration practices.

6. Customization SS sintered filter cartridges can be tailored to meet specific requirements, including pore size, diameter, and length. This customization ensures that the filtration system is optimized for the particular application, enhancing performance and efficiency.

Conclusion

As industries continue to seek cost-effective and sustainable solutions to their filtration needs, SS sintered filter cartridges stand out as a sophisticated option. Their unique combination of durability, high filtration efficiency, and reusability offers substantial advantages over traditional filter media. In an ever-evolving industrial landscape, investing in stainless steel sintered filter technology not only promotes operational efficiency but also aligns with growing environmental responsibilities. As the demand for high-quality filtration solutions rises, SS sintered filter cartridges are poised to play a crucial role in meeting these challenges while ensuring superior performance across various applications.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: