ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Mar . 04, 2025 00:49 Back to list

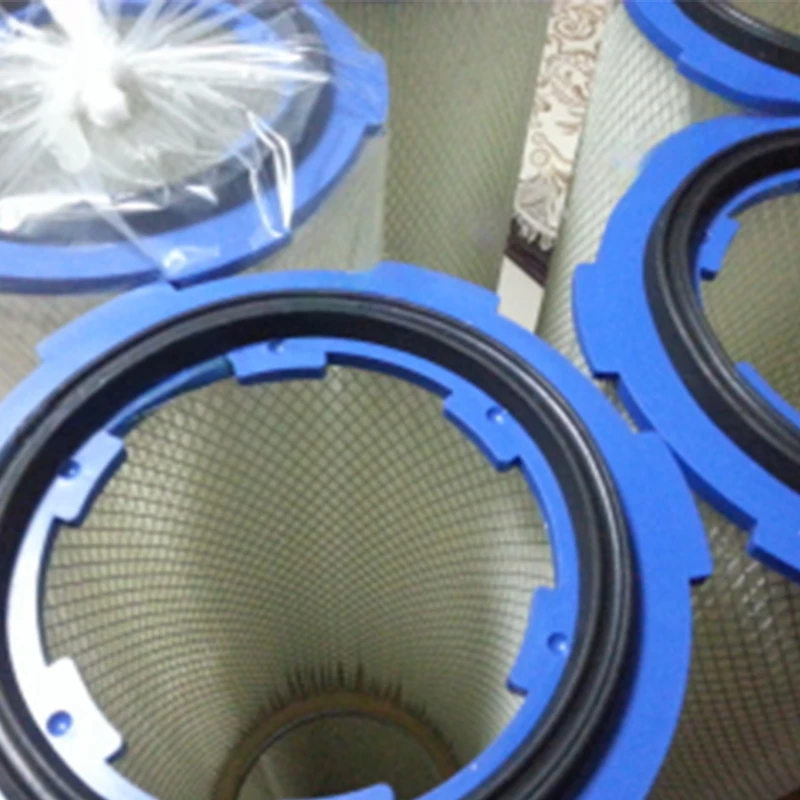

ss sintered filter cartridge

Unlocking the Potential of SS Sintered Filter Cartridges Your Ultimate Resource

2. Food and Beverage These cartridges are used to maintain hygiene and consistency in production, filtering out unwanted particles and ensuring that products meet the highest quality standards. 3. Oil and Gas In the oil and gas sector, where conditions can be exceedingly harsh, ss sintered filter cartridges are employed to remove contaminants from hydraulic fluids and natural gas, optimizing performance and preventing equipment damage. 4. Water Treatment The robust nature of these cartridges allows them to be used in water treatment plants, where they effectively remove impurities, contributing to safe and clean water supplies. Expertise in Deployment Successful deployment of ss sintered filter cartridges is reliant on expert evaluation and understanding of specific application requirements. Professionals in the field leverage their extensive experience to select cartridges with appropriate pore sizes and configurations, ensuring optimal performance and compliance with industry standards. Authoritativeness in Innovation Manufacturers of ss sintered filter cartridges continually push the boundaries of innovation, incorporating cutting-edge technologies to enhance filter performance. This authoritative approach not only sets industry benchmarks but also inspires confidence in users seeking reliable filtration solutions. Trustworthiness and Reliability SS sintered filter cartridges are trusted for their consistent performance and reliability. Their adoption across critical industries underscores their reputation as a dependable choice for challenging filtration tasks. Regularly subjected to rigorous testing, these cartridges are certified to meet stringent quality standards, affirming their trustworthiness. Conclusion In an era where precision and reliability are paramount, ss sintered filter cartridges emerge as a vital component of industrial filtration systems. Their unparalleled durability, efficiency, and adaptability confirm their standing as premier providers of filtration solutions. As industries continue to evolve, the role of these advanced cartridges will only grow, driving innovation and ensuring the highest standards of operational effectiveness.

2. Food and Beverage These cartridges are used to maintain hygiene and consistency in production, filtering out unwanted particles and ensuring that products meet the highest quality standards. 3. Oil and Gas In the oil and gas sector, where conditions can be exceedingly harsh, ss sintered filter cartridges are employed to remove contaminants from hydraulic fluids and natural gas, optimizing performance and preventing equipment damage. 4. Water Treatment The robust nature of these cartridges allows them to be used in water treatment plants, where they effectively remove impurities, contributing to safe and clean water supplies. Expertise in Deployment Successful deployment of ss sintered filter cartridges is reliant on expert evaluation and understanding of specific application requirements. Professionals in the field leverage their extensive experience to select cartridges with appropriate pore sizes and configurations, ensuring optimal performance and compliance with industry standards. Authoritativeness in Innovation Manufacturers of ss sintered filter cartridges continually push the boundaries of innovation, incorporating cutting-edge technologies to enhance filter performance. This authoritative approach not only sets industry benchmarks but also inspires confidence in users seeking reliable filtration solutions. Trustworthiness and Reliability SS sintered filter cartridges are trusted for their consistent performance and reliability. Their adoption across critical industries underscores their reputation as a dependable choice for challenging filtration tasks. Regularly subjected to rigorous testing, these cartridges are certified to meet stringent quality standards, affirming their trustworthiness. Conclusion In an era where precision and reliability are paramount, ss sintered filter cartridges emerge as a vital component of industrial filtration systems. Their unparalleled durability, efficiency, and adaptability confirm their standing as premier providers of filtration solutions. As industries continue to evolve, the role of these advanced cartridges will only grow, driving innovation and ensuring the highest standards of operational effectiveness.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: