ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Feb . 18, 2025 09:12 Back to list

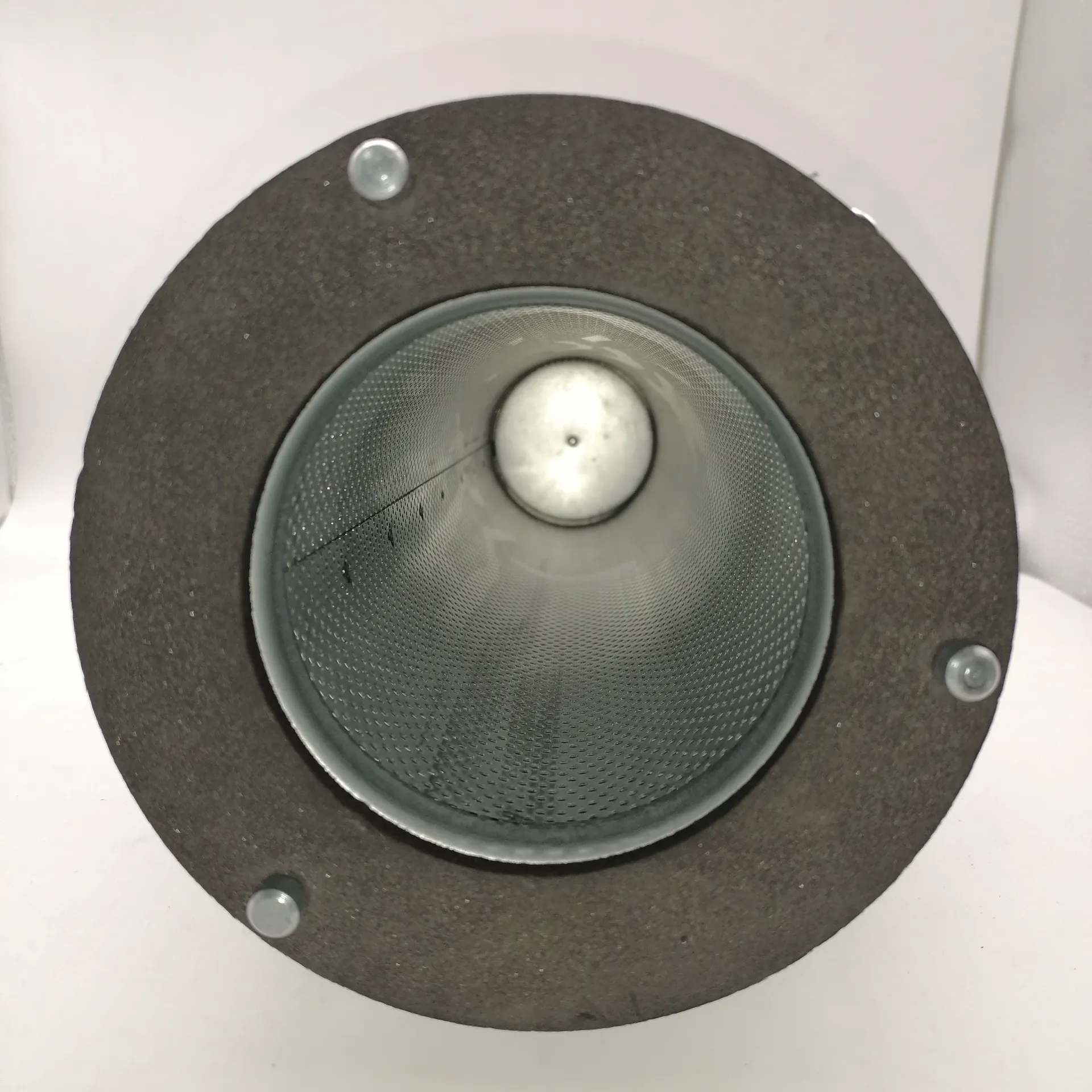

sintered metal filter cartridge

In the ever-evolving world of industrial filtration, the stainless steel (SS) sintered filter cartridge stands out as a beacon of innovation and reliability. For industries seeking robust filtration solutions, this product offers unparalleled benefits, ensuring both efficiency and longevity. This article delves into the unique attributes and advantages of SS sintered filter cartridges, with insights derived from real-world applications and expert analysis.

Trustworthiness of the SS sintered filter cartridge is further amplified by compliance with international standards. The rigorous testing and certification processes these filters undergo ensure they meet—and often exceed—industry benchmarks. This guarantees that end-users can trust the performance consistency and safety of the product, crucial factors in applications where filtration quality is directly linked to product purity and environmental safety. Additionally, the sustainable aspect of SS sintered filter cartridges cannot be overlooked. In an era where sustainability is as important as performance, these filters hold an edge. The durability and reusability of stainless steel mean fewer replacements and reduced environmental impact. After their lifecycle, these filters can be recycled, aligning with global efforts to minimize industrial waste. In conclusion, the SS sintered filter cartridge offers a fusion of cutting-edge technology and practical advantages, making it indispensable for modern industrial applications. Its ability to deliver precise, reliable filtration with minimal maintenance establishes it as a superior choice in the market. As industries continue to seek efficient and sustainable filtration solutions, the role of SS sintered filters becomes increasingly pivotal, providing a future-ready option embraced by experts worldwide.

Trustworthiness of the SS sintered filter cartridge is further amplified by compliance with international standards. The rigorous testing and certification processes these filters undergo ensure they meet—and often exceed—industry benchmarks. This guarantees that end-users can trust the performance consistency and safety of the product, crucial factors in applications where filtration quality is directly linked to product purity and environmental safety. Additionally, the sustainable aspect of SS sintered filter cartridges cannot be overlooked. In an era where sustainability is as important as performance, these filters hold an edge. The durability and reusability of stainless steel mean fewer replacements and reduced environmental impact. After their lifecycle, these filters can be recycled, aligning with global efforts to minimize industrial waste. In conclusion, the SS sintered filter cartridge offers a fusion of cutting-edge technology and practical advantages, making it indispensable for modern industrial applications. Its ability to deliver precise, reliable filtration with minimal maintenance establishes it as a superior choice in the market. As industries continue to seek efficient and sustainable filtration solutions, the role of SS sintered filters becomes increasingly pivotal, providing a future-ready option embraced by experts worldwide.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: