Tel:

+8615930870079

Tel:

+8615930870079

Dec . 28, 2024 09:36 Back to list

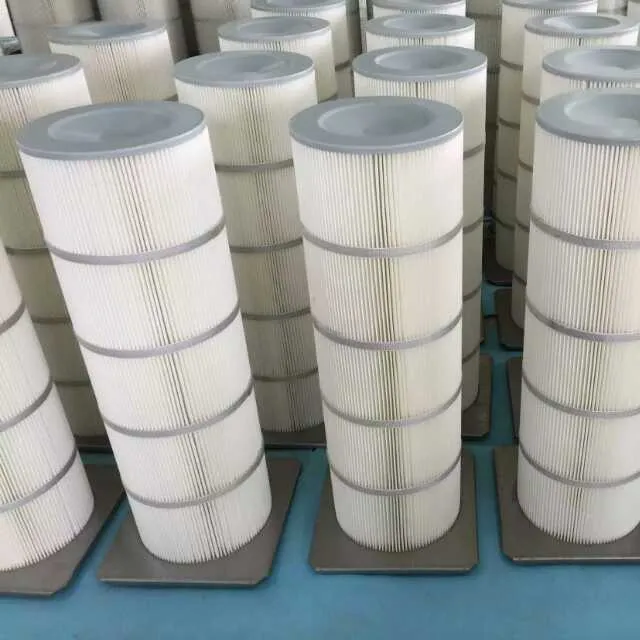

ss sintered filter cartridge

A Comprehensive Overview of SS Sintered Filter Cartridges

In today's world, where cleanliness and purity of liquids and gases are paramount, the demand for effective filtration solutions has skyrocketed. Among the myriad options available, SS (stainless steel) sintered filter cartridges have emerged as a versatile and efficient choice for various industrial applications. This article delves into the properties, advantages, applications, and maintenance of SS sintered filter cartridges.

Understanding SS Sintered Filter Cartridges

SS sintered filter cartridges are made from stainless steel by a process known as sintering. This involves compressing and heating powdered stainless steel, resulting in a porous, rigid structure that can trap particles while allowing fluids or gases to pass through. The sintering process creates a network of interconnected pores, which is essential for filtration performance.

These cartridges are known for their durability, high resistance to chemical corrosion, and the ability to withstand elevated temperatures. The materials used in their construction make them suitable for challenging environments where traditional filter media may fail.

Advantages of SS Sintered Filter Cartridges

1. Durability and Longevity Stainless steel is inherently resistant to rust and corrosion, which means that SS sintered filter cartridges can last significantly longer than their plastic or paper counterparts. This longevity translates to reduced maintenance costs and less frequent replacements.

2. High Filtration Efficiency The intricate design of sintered filters allows for superior filtration efficiency. They can remove particulate contaminants as small as a few microns, making them ideal for applications requiring high purity levels.

3. Reusability One of the standout features of SS sintered filter cartridges is their ability to be cleaned and reused. They can withstand backwashing and chemical cleaning processes, making them environmentally friendly and cost-effective in the long run.

4. Versatility These cartridges can be tailored to meet specific filtration requirements, including varying pore sizes and configurations. This adaptability makes them suitable for diverse industries, including pharmaceuticals, food and beverage, chemicals, and oil and gas.

5. High Flow Rates The design of sintered filters allows for higher flow rates compared to other filtration methods. This characteristic is particularly beneficial in applications where the volume of fluid processed is critical.

Applications of SS Sintered Filter Cartridges

SS sintered filter cartridges are employed across various sectors

ss sintered filter cartridge

- Pharmaceutical and Biotechnology In these industries, ensuring that products are free from contaminants is essential. SS sintered filter cartridges are used for sterile filtration, water purification, and in the production of injectables.

- Food and Beverage The need for clean water and ingredients in food production makes these filters invaluable. They are used in processes such as beer brewing, wine clarification, and dairy processing.

- Chemical Processing The chemical industry often deals with aggressive substances that can corrode other materials. SS sintered filters can handle a wide range of chemicals without compromising their structural integrity.

- Oil and Gas In oil refineries and natural gas processing, sintered filters help to separate solids and prevent equipment fouling, thereby enhancing operational efficiency.

Maintenance and Care of SS Sintered Filter Cartridges

To maximize the lifespan and performance of SS sintered filter cartridges, regular maintenance is crucial

1. Cleaning Depending on the application, the frequency of cleaning can vary. However, backwashing or soaking in appropriate cleaning agents is recommended to remove built-up debris.

2. Inspection Regularly check for signs of wear or damage. Addressing issues promptly can prevent premature replacement and maintain filtration efficiency.

3. Flow Rate Monitoring Keep an eye on the flow rates. A decrease may indicate clogging, warranting cleaning or replacement.

4. Chemical Compatibility Always use cleaning agents and process fluids that are compatible with stainless steel to prevent damage to the cartridges.

Conclusion

SS sintered filter cartridges represent an advanced filtration solution that offers durability, efficiency, and versatility for a range of industrial applications. By investing in these high-quality filters, industries can not only ensure operational efficiency but also uphold stringent standards of purity and safety. Their long-term cost-effectiveness and environmental benefits further cement their position as a preferred choice in the realm of filtration technology. As the demand for clean processes continues to rise, SS sintered filter cartridges will undoubtedly play a crucial role in meeting these challenges.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: