ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jul . 12, 2024 03:13 Back to list

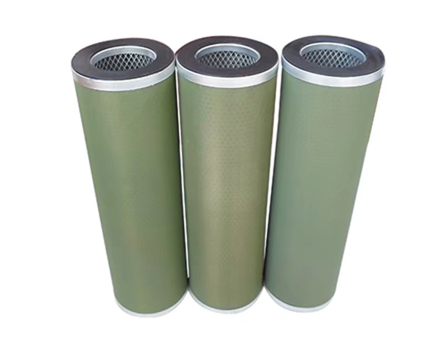

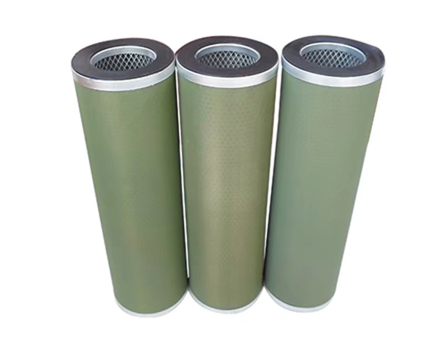

Sintered metal filter cartridge for efficient and reliable filtration in industrial applications

Sintered metal filter cartridges are an essential component in a wide range of industrial applications. These filters are made from metal powders that are compacted and heated to form a solid piece with interconnected pores. The sintering process results in a durable and porous material that allows for efficient filtration of liquids and gases.

One of the key advantages of sintered metal filter cartridges is their ability to withstand high temperatures and pressures. This makes them ideal for use in applications where standard filter cartridges may fail. Additionally, the material used in sintered metal filters is resistant to corrosion, making them suitable for use in harsh environments.

The structure of sintered metal filter cartridges allows for precise control over the size and distribution of pores, making it possible to tailor the filter to specific filtration requirements. This customization ensures that the filter provides optimal performance and efficiency for the intended application.

Sintered metal filter cartridges are used in a variety of industries, including oil and gas, pharmaceutical, food and beverage, and automotive

sintered metal filter cartridge. In the oil and gas industry, these filters are used to remove contaminants from drilling fluids and hydraulic fluids. In the pharmaceutical industry, sintered metal filters are utilized in the production of drugs and vaccines. In the food and beverage industry, these filters are used to clarify liquids and remove impurities. In the automotive industry, sintered metal filters are used in air and fuel filtration systems. Overall, sintered metal filter cartridges offer a reliable and cost-effective solution for a wide range of filtration needs. Their durability, temperature resistance, and customizable pore structure make them an essential component in many industrial processes. Whether filtering liquids or gases, sintered metal filters provide efficient and effective filtration that helps maintain the quality and purity of the end product.

sintered metal filter cartridge. In the oil and gas industry, these filters are used to remove contaminants from drilling fluids and hydraulic fluids. In the pharmaceutical industry, sintered metal filters are utilized in the production of drugs and vaccines. In the food and beverage industry, these filters are used to clarify liquids and remove impurities. In the automotive industry, sintered metal filters are used in air and fuel filtration systems. Overall, sintered metal filter cartridges offer a reliable and cost-effective solution for a wide range of filtration needs. Their durability, temperature resistance, and customizable pore structure make them an essential component in many industrial processes. Whether filtering liquids or gases, sintered metal filters provide efficient and effective filtration that helps maintain the quality and purity of the end product.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: