Tel:

+8615930870079

Tel:

+8615930870079

Oct . 20, 2024 17:40 Back to list

silo filter cartridge

Understanding Silo Filter Cartridges Key Components for Effective Filtration in Industrial Applications

In various industrial processes, the need for effective filtration systems cannot be overstated. One crucial element in these systems is the silo filter cartridge, which plays a vital role in ensuring the quality and purity of stored materials. This article delves into the functionality, importance, and maintenance of silo filter cartridges, shedding light on why they are indispensable in many applications.

What is a Silo Filter Cartridge?

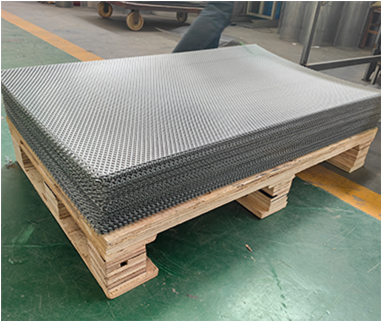

A silo filter cartridge is a specialized filtering device used to separate dust and contaminants from the air in silos or storage containers. These cartridges are designed to capture particulate matter while allowing clean air to escape, thereby maintaining air quality and preventing the contamination of materials stored within the silo. Typically, they are constructed using high-quality filter media and are designed to withstand the harsh conditions often found in industrial environments, such as high temperatures and abrasive materials.

Functionality and Design

Silo filter cartridges operate on the principle of particulate filtration, which involves drawing in air and passing it through a filter media that traps unwanted particles. This process is essential for maintaining the integrity of the materials being stored, especially in industries like agriculture, pharmaceuticals, and food processing, where even small amounts of contamination can compromise product quality.

The design of silo filter cartridges often incorporates features that enhance their efficiency. These may include pleated construction, which increases the surface area for filtration while minimizing resistance to airflow. Additionally, some cartridges are equipped with a pulse-jet cleaning mechanism. This feature enables periodic cleaning of the filter, ensuring that it remains effective over time and reducing the need for frequent replacements.

silo filter cartridge

Importance of Silo Filter Cartridges

The significance of silo filter cartridges extends beyond mere dust removal. They play a critical role in promoting workplace safety by minimizing dust emissions that can pose health risks to workers. Moreover, effective filtration prevents material loss and contamination, which can lead to financial losses and damage to brand reputation. In industries that handle hazardous materials, such as chemicals or powders, the importance of accurate filtration cannot be overstated, as it directly impacts regulatory compliance and environmental sustainability.

Maintenance and Longevity

To maximize the lifespan of silo filter cartridges and maintain optimal performance, regular maintenance is essential. This includes monitoring the pressure differential across the cartridge, which can indicate when it is time for cleaning or replacement. Inspections should also be performed to check for signs of wear and tear, especially if the cartridges are subjected to heavy-duty applications.

Implementing a proactive maintenance schedule allows facilities to avoid costly downtimes and ensures a consistent quality of materials. Depending on the specific application and operating conditions, the lifespan of silo filter cartridges can vary, but with proper care, they can often last for several years.

Conclusion

In summary, silo filter cartridges are fundamental components in the realm of industrial filtration systems. Their ability to efficiently remove contaminants from the air contributes to product purity, workplace safety, and regulatory compliance. By understanding their functionality and importance, as well as committing to regular maintenance, businesses can enhance their operational efficiency and ensure the longevity of their filtering systems. As industries continue to evolve and face new challenges, the role of silo filter cartridges will remain crucial in safeguarding both the products they offer and the environment in which they operate.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: