Tel:

+8615930870079

Tel:

+8615930870079

Nov . 14, 2024 07:25 Back to list

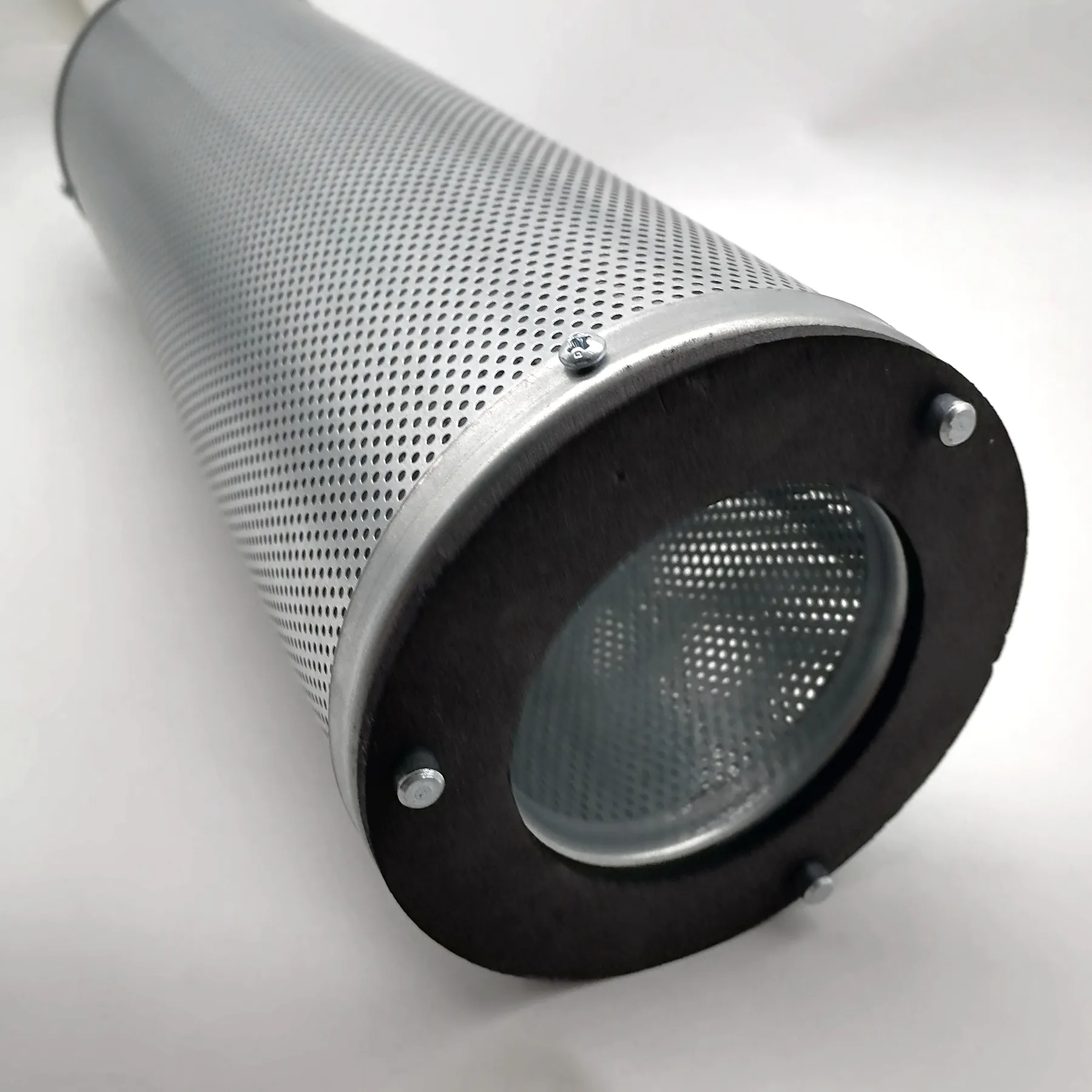

metal filter cartridge

Understanding Metal Filter Cartridges A Comprehensive Guide

Metal filter cartridges are essential components in various industrial applications, serving to purify fluids and gases by removing contaminants. These cartridges are designed with a specific focus on durability and efficiency, making them ideal for high-pressure and high-temperature environments. This article delves into the advantages, applications, and maintenance of metal filter cartridges.

What is a Metal Filter Cartridge?

A metal filter cartridge is a filtration device made primarily of metal materials such as stainless steel or other alloys. These cartridges feature a porous structure that allows liquid or gas to pass through while trapping impurities, particles, and other unwanted substances. They can be configured in different shapes, sizes, and filtration grades to meet the specific requirements of various processes.

Advantages of Metal Filter Cartridges

The use of metal filter cartridges offers numerous advantages, making them a preferred choice in several industries

1. Durability Metal filters can withstand extreme temperatures and pressures, making them suitable for demanding environments where plastic filters might fail.

2. Chemical Resistance Stainless steel and other alloys are resistant to corrosion and chemical degradation. This chemical stability ensures that the filter maintains its integrity and performance over time, especially in corrosive applications.

3. Reusability Unlike disposable filters, metal filter cartridges can often be cleaned and reused. This feature not only reduces waste but also minimizes operational costs for businesses, as they do not have to purchase replacements frequently.

4. Improved Filtration Efficiency Metal cartridges can achieve finer filtration levels compared to traditional filtration media, providing enhanced purity for critical applications in sectors like pharmaceuticals, food processing, and electronics.

Applications of Metal Filter Cartridges

Metal filter cartridges find applications in a wide range of industries

metal filter cartridge

- Chemical Processing In the chemical industry, these filters are crucial for removing impurities from corrosive liquids and gases, ensuring product quality and compliance with safety standards.

- Pharmaceuticals The need for sterile and contaminant-free environments makes metal filter cartridges essential in pharmaceutical manufacturing. They help in maintaining the integrity of drugs and preventing contamination during production.

- Food and Beverage Metal filters are commonly used in breweries, wineries, and food production facilities to ensure that final products are free from unwanted particles, enhancing quality and safety.

- Oil and Gas In oil and gas extraction and refining, metal filter cartridges help purify the fluids involved by removing particulates, which can damage equipment and reduce efficiency.

- Aerospace and Automotive In these highly regulated industries, metal filters are utilized to maintain the purity of lubricants and fuels, ensuring optimal performance and safety.

Maintenance and Care

To maximize the lifespan and functionality of metal filter cartridges, proper maintenance is essential

- Regular Cleaning Depending on the application, metal filters should be cleaned periodically to remove accumulated particles and maintain optimal flow rates.

- Inspection Routine inspections are vital for identifying any damage or wear that could affect performance. Early detection of issues can prevent costly downtime.

- Replacement While metal cartridges are reusable, they do have a finite lifespan. Operators should adhere to manufacturer recommendations regarding replacement schedules to ensure continuous reliability.

Conclusion

Metal filter cartridges are a robust and effective solution for filtration in various industries. Their durability, chemical resistance, and efficiency make them invaluable in applications where contamination control is critical. With proper maintenance and care, these cartridges can provide long-lasting service, contributing to improved productivity and quality in industrial processes.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: