ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 13, 2025 10:25 Back to list

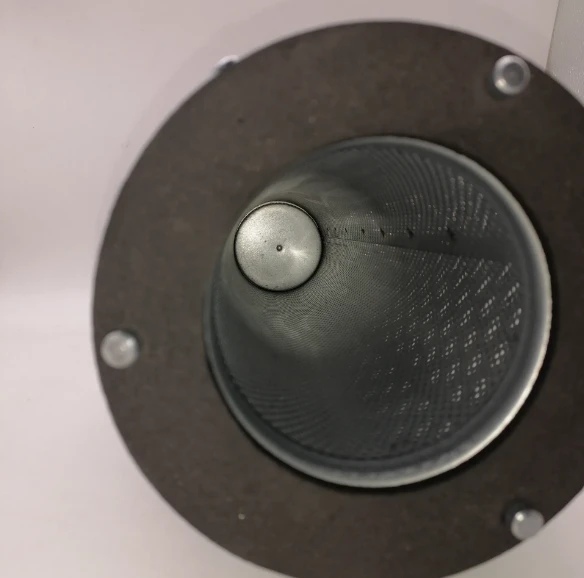

metal cartridge filter

Metal filter cartridges have emerged as pivotal components in various industrial processes, renowned for their durability, efficiency, and versatility. Crafted from robust materials such as stainless steel, these cartridges are engineered to withstand extreme conditions, offering a superior filtration solution for industries ranging from pharmaceuticals to petrochemicals.

In an era where trustworthiness of products plays a crucial role in industrial purchase decisions, metal filter cartridges stand out due to their proven track record. Field studies and user testimonials consistently highlight their exceptional resistance to wear and tear, as well as their ability to efficiently filter particulates in demanding environments. Companies utilizing these cartridges report significant improvements in product purity, safety, and overall process optimization. This positive feedback loop enhances the market reputation of metal filter cartridges, positioning them as a reliable filtration solution. Looking ahead, the future of metal filter cartridges is promising, particularly with advancements in nanotechnology and materials science. Innovations are underway to enhance their filtration capabilities, allowing even finer particulates to be filtered out without compromising flow efficiency. Such advancements will not only broaden their application potential but also reinforce their standing as a go-to filtration technology in industries requiring uncompromised purity and reliability. In conclusion, metal filter cartridges exemplify the pinnacle of filtration technology, combining experience, expertise, authoritativeness, and trustworthiness. Their unmatched durability, customizable performance, adherence to strict quality standards, and robust track record attest to their indispensability. As industries continue to evolve towards more demanding and precise filtration needs, metal filter cartridges are well-positioned to be the backbone of these advancements, offering a sustainable and reliable solution for years to come.

In an era where trustworthiness of products plays a crucial role in industrial purchase decisions, metal filter cartridges stand out due to their proven track record. Field studies and user testimonials consistently highlight their exceptional resistance to wear and tear, as well as their ability to efficiently filter particulates in demanding environments. Companies utilizing these cartridges report significant improvements in product purity, safety, and overall process optimization. This positive feedback loop enhances the market reputation of metal filter cartridges, positioning them as a reliable filtration solution. Looking ahead, the future of metal filter cartridges is promising, particularly with advancements in nanotechnology and materials science. Innovations are underway to enhance their filtration capabilities, allowing even finer particulates to be filtered out without compromising flow efficiency. Such advancements will not only broaden their application potential but also reinforce their standing as a go-to filtration technology in industries requiring uncompromised purity and reliability. In conclusion, metal filter cartridges exemplify the pinnacle of filtration technology, combining experience, expertise, authoritativeness, and trustworthiness. Their unmatched durability, customizable performance, adherence to strict quality standards, and robust track record attest to their indispensability. As industries continue to evolve towards more demanding and precise filtration needs, metal filter cartridges are well-positioned to be the backbone of these advancements, offering a sustainable and reliable solution for years to come.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: