Tel:

+8615930870079

Tel:

+8615930870079

Aug . 15, 2024 01:34 Back to list

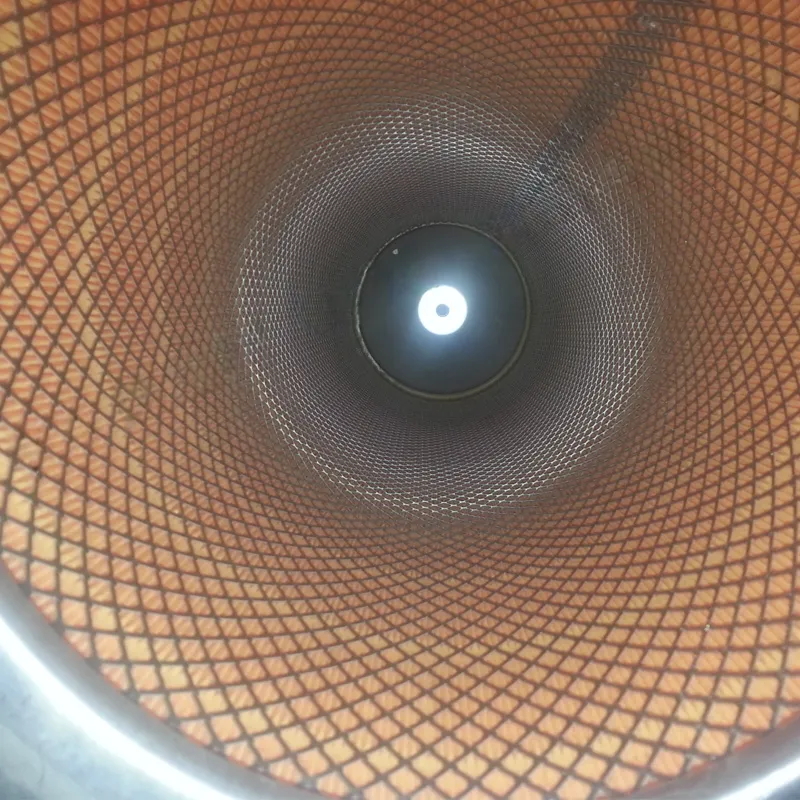

High-Efficiency Industrial Air Filter Cartridges for Enhanced Air Quality and Performance Optimization

Industrial Air Filter Cartridges Essential Components for Clean Air

In today's industrial landscape, maintaining clean air is not just a regulatory requirement; it is also a critical aspect of ensuring the health and safety of employees. One of the key components in achieving clean air in industrial settings is the air filter cartridge. These cartridges serve as the first line of defense against airborne contaminants, ensuring that the air quality is maintained at safe levels for workers and machinery alike.

Understanding Air Filter Cartridges

Air filter cartridges are designed to capture dust, particulate matter, and various other pollutants present in the air. They are used in a variety of applications, ranging from manufacturing plants to warehouse facilities. The cartridges are generally made from a combination of materials, including fiberglass, synthetic media, and pleated fabric, which allow for effective filtration while maximizing airflow.

The efficiency of an air filter cartridge is typically measured by its Minimum Efficiency Reporting Value (MERV) rating. The MERV scale ranges from 1 to 16, with higher numbers indicating a greater capacity to trap smaller particles. Industries that deal with fine dust, chemical vapors, or biological contaminants might require high-MERV cartridges to ensure comprehensive filtration.

Importance of Regular Maintenance

While air filter cartridges are durable, they are not designed to last indefinitely. Regular maintenance and timely replacement of these cartridges are essential to ensure their optimal performance. Over time, cartridges can become clogged with particles, which not only reduces their efficacy but can also lead to increased energy consumption in HVAC systems. This not only poses health risks but can also lead to higher operational costs.

industrial air filter cartridges

Establishing a routine inspection schedule can help in monitoring the condition of air filter cartridges. Organizations should consider using pressure drop indicators to determine when a filter is at its maximum capacity and needs to be replaced. By adhering to a proactive maintenance routine, industries can save money, reduce downtime, and ensure a healthier work environment.

Innovations in Air Filtration Technology

The field of air filtration is continually evolving, with new technologies emerging to enhance the effectiveness of air filter cartridges. One such innovation is the use of nanotechnology to improve filtration efficiency. Nanofibers can trap particles at a microscopic level, significantly enhancing the capability of traditional filter media. This not only improves air quality but also extends the service life of the filters.

Moreover, some modern air filter cartridges come equipped with smart technology that allows for real-time monitoring of air quality and filter saturation levels. Sensors can track particle levels and alert maintenance teams when it's time for a replacement, ultimately leading to smarter operational practices and improved health outcomes.

Conclusion

Air filter cartridges are a crucial part of industrial operations, playing an essential role in ensuring clean air and maintaining the health and safety of workers. As industries continue to evolve, so do the technologies surrounding air filtration. By investing in high-quality cartridges and ensuring regular maintenance, companies can foster a safer work environment while also achieving operational efficiency. In a world where air quality is increasingly becoming a pressing concern, the importance of effective air filtration cannot be underestimated.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: