Tel:

+8615930870079

Tel:

+8615930870079

Aug . 01, 2025 06:20 Back to list

High-Efficiency Dust Collector Supplier Powered by GPT-4 Turbo

Explore the definitive guide to High Efficiency Manufacturer Supplies Dust Collector solutions, with a deep dive into industry trends, manufacturing workflow, technical benchmarks, and real-world application scenarios.

1. Global Dust Collector Market Trends & Outlook (2024+)

The dust collection industry has entered a new era of high-efficiency filtration, driven by increasing regulatory demands regarding workplace air quality (OSHA, EPA), growing awareness of environmental responsibility, and innovations in filter technology. According to Markets & Markets, the global dust collector market size is expected to reach USD 9.8 billion by 2027, with an average CAGR of 4.3% from 2021 to 2027.

- Key Growth Drivers: Stricter emission norms (ISO 14001), demand for energy efficiency, and rising adoption across metallurgy, cement, and chemical sectors.

- Technology Focus: Baghouse, cartridge, and electrostatic collectors dominate, but newer products like High Efficiency Manufacturer Supplies Dust Collector demonstrate significant advancements in lifecycle cost and filtration precision.

2. Product Introduction: High Efficiency Manufacturer Supplies Dust Collector

The High Efficiency Manufacturer Supplies Dust Collector is a next-generation industrial dust collection system, precision-engineered to provide superior particulate filtration down to 0.3μm at efficiencies ≥99.7%. Certified to ISO 16890 and ANSI Z9.2 standards, this system is optimized for demanding applications in petrochemical, metallurgical, cement, pharmaceutical, and heavy-manufacturing industries.

- Product Webpage: Official Product Link

- Certifications: ISO 9001, ISO 14001, CSA, CE Mark, RoHS

- Key Features: High-efficiency composite filter media, modular design, anticorrosive surface, energy-efficient fans, predictive maintenance sensors

- Industries: Petrochemical, metallurgy, cement, municipal, food processing, water & wastewater, electronic assembly, mining, and more

3. Technical Specifications at a Glance

| Parameter | High Efficiency Manufacturer Supplies Dust Collector | Conventional Dust Collector (Reference) |

|---|---|---|

| Filtration efficiency | ≥99.7% (@0.3μm) | 92-97% (@1μm) |

| Airflow Capacity | 6,000 – 40,000 m³/h | 5,000 – 25,000 m³/h |

| Filter Media | PTFE-coated nanofiber, cellulose + polyester composite | Standard polyester felt |

| Energy Consumption | 0.55 – 1.8 kWh/m³/h (20% lower) | 0.7 – 2.3 kWh/m³/h |

| Pressure Drop | Low (80 – 120 Pa) | 110 – 180 Pa |

| Corrosion Resistance | Excellent (marine-grade 316SS, epoxy coated) | Moderate |

| Operational Life | 50,000+ h (avg. 6–8 yrs) | 20,000–30,000 h (avg. 3–4 yrs) |

4. Visualizing Performance: Key Metrics Analysis

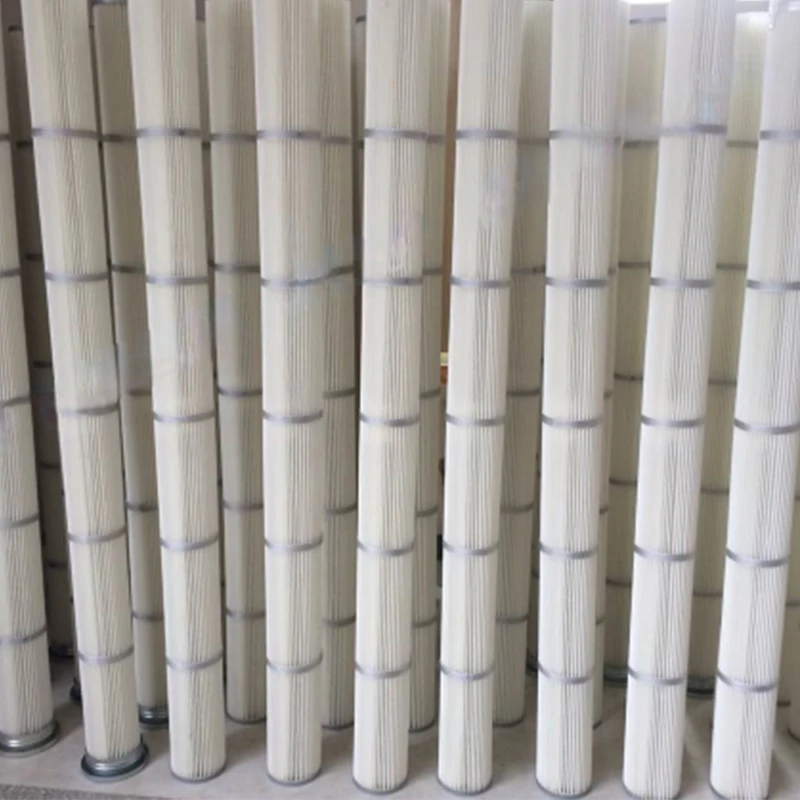

High Efficiency Manufacturer Supplies Dust Collector

5. Craftsmanship: Manufacturing & Quality Assurance Workflow

- Material Selection — Premium marine-grade 316L stainless steel, high-impact carbon steel, nano-PTFE, and composite filter fibers. All incoming materials subject to ISO 9001 batch traceability checks.

- Cutting & Shaping — Advanced CNC laser cutting and robotic plasma welding achieve sub-0.2 mm accuracy on housing and internal baffles.

- Surface Treatment — Multi-stage deep cleaning, then anti-corrosive epoxy, powder-coated or passivation finish (per ISO 9227/NSS).

- Assembly — Robotic arm assembly & torque-regulated bolting minimize seal failures, plus custom fit for OEM adaptation.

- Filter Module Integration — Precision-folded nanofiber cartridges tested for pleat stability and airflow uniformity; ISO 16890 & EN 1822 tested.

- Inspection & Testing — Each unit passes leak, pressure, and corrosion simulation; efficiency validated on certified particle counters. Randomized long-cycle endurance testing validates projected 6–8 year service life.

- Palletization & Pre-shipment QA — Secure packaging per ASTM D3951, QR code tracking, and final batch QA logs archived for 8 years.

- Manufacturing Method: Combination of casting (for heavy base), CNC machining (chambers, baffles), precision press-fitting (filter modules), and MIG/TIG welding (external seams).

- Testing Standards: ISO 16890, EN 779, ANSI Z9.2, customized client-side validation (per project requirement).

- Product Lifecycle: 6–8 years for main module, filter cartridges typically 1.5–2 years service interval.

- Applicable Industries: Refineries, steelworks, municipal solid waste, mining, cement, power plants, food & beverage, microelectronics.

Workflow Diagram: Dust Collector Production

- Step 1: Raw Material Inbound & QC →

- Step 2: CNC Cutting & Baffle Forming →

- Step 3: Surface Coating →

- Step 4: Component Assembly + Seal Fit →

- Step 5: Filter Integration & Validation →

- Step 6: Final QA Testing →

- Step 7: Packaging & Shipment

6. Technology Advantages: Standing Out in a Competitive Landscape

- Superior Particle Filtration: Removes sub-micron particles, fume, oil mist — including PM2.5, with ISO 16890 EPM1 ≥99.7%.

- Lower Energy Use: Enhanced aerodynamics and low-pressure drop reduce power draw by 18-24% compared to typical baghouse systems.

- Anticorrosion & Reliability: All wetted parts are marine 316L or powder-epoxy-coated, granting high chemical/abrasion resistance.

- Smart Monitoring: Optional IIOT sensor module (Modbus/TCP/IP enabled) for predictive alerts and maintenance scheduling.

- Customization Friendly: Modular, easily scalable — suitable for retrofit, new OEM integration, or high-volume line installation.

- Regulatory Compliance: Fully meets EU CE, ISO 14001, NFPA, and U.S. OSHA (1910.94) dust control mandates.

| Brand/Model | Efficiency (PM2.5) | Pressure Drop (Pa) | Energy Consumption | Corrosion Features |

|---|---|---|---|---|

| High Efficiency Manufacturer Supplies Dust Collector | ≥99.7% | 80–120 | Low (0.55–1.8 kWh/m³h) | Marine 316L, Epoxy Multi-Coat |

| Donaldson Torit DFO | 98-99% | 120–160 | 1.1–2.0 kWh/m³h | Epoxy, No SS option |

| AAF OptiFlo RC | 98% | 130–170 | 0.9–2.1 kWh/m³h | Standard 304SS |

| Camfil Gold Series | 97–99% | 130–155 | 0.9–1.9 kWh/m³h | Powder Coated |

7. Customization: Tailored Solutions for Diverse Industries

- Project Consultation: Pre-installation site analysis, dust load simulation, and flow modeling (CFD), delivered by industry-certified engineers.

- Specification Flexibility: Flow rates 6,000–40,000 m³/h; modular expansion to 80,000+ m³/h; pressure, temperature, and corrosion-resistance variations per client spec.

- OEM/ODM Capability: Panel style, filter media grade, control integration and branding adaptations available.

- Delivery & Turnkey Integration: Standard systems ready in 20–30 working days; custom, multi-module projects in 45–60 days with on-site commissioning.

- Geo-Specific Compliance: All solutions engineered to satisfy target regional safety, ergonomic, and emission standards.

8. Real-World Applications & Client Success Stories

- Petrochemical: Controls sulfuric, hydrocarbon, and catalyst dust with continuous, automated self-cleaning under hazardous gas conditions.

- Steel & Metallurgy: Handles blast furnace, sintering line, and grinding emissions with minimal filter blinding under extreme heat/corrosive vapor.

- Water & Wastewater: Odor and bioaerosol control in urban utility plants; maintains compliance with EPA and EUROPEAN directives.

- Electronics/PCB: Cleanroom-adapted options, supporting ISO 14644-1 classification with ultra-fine dust (0.1 μm) capture.

- Food & Beverage: USDA/FDA-compatible filter cartridges, HACCP cleanable housings for grain, lactose, and sugar dust.

Case Study: Steel Plant (Vietnam)

Problem: Aggressive iron oxide and acid vapor dust, with high temperature.Solution: 2 x 20,000 m³/h High Efficiency Manufacturer Supplies Dust Collector modules with 316L wetted parts, remote Modbus monitoring.

Result: 99.7%+ dust removal, 24% downtime reduction, zero unplanned shutdowns in first 30 months.

Case Study: Food Processing (Turkey)

Problem: Organic sugar/salt dust, hygiene requirements; fine particulateSolution: FDA-grade filters, all-wet cleanable housing, pulse-jet cleaning optimized for food grade.

Result: Low downtime, SGS-certified 99.8% removal, easy sanitation.

Case Study: Municipal Waste Incinerator (France)

Problem: High-dust load, sticky particles, strict EU emission limits.Solution: Tandem High Efficiency Manufacturer Supplies Dust Collector systems with advanced PTFE cartridges.

Result: PM10 reduced to <3μg/m³, exceeding EU Directive 2010/75/EU.

9. Technical FAQ: Professional FAQ on High Efficiency Manufacturer Supplies Dust Collector

- Q1. What is the primary filter media and its benefit?

- Answer: The core filter uses PTFE-coated nanofiber with a cellulose-polyester composite, offering extremely fine filtration (≥99.7% @0.3μm), high mechanical strength, and excellent anti-caking performance.

- Q2. What are the available sizes/specifications?

- Answer: Standard modules handle 6,000–40,000 m³/h; custom sizing is possible for airflows up to 80,000 m³/h. Connection flanges, height, and inlet layouts can be adapted per project.

- Q3. Which international installation standards does the collector conform to?

- Answer: Compliant with ISO 16890 (filtration), ANSI Z9.2 (ventilation), EN 1090 (fabrication/welding), and IEC 60204 (electrical safety).

- Q4. What is the standard service life and maintenance routine?

- Answer: The housing is rated 6–8 years; filter cartridges generally 1.5–2 years per typical load. Integrated pulse-jet cleaning and differential pressure sensors help extend intervals.

- Q5. How does the corrosion resistance compare with competitors?

- Answer: Material options include 316L, duplex stainless, or custom alloy; full epoxy multi-coating. Salt spray (ISO 9227) and acid tests consistently outperform standard 304SS or uncoated systems.

- Q6. Are ATEX/IECEx hazardous area models available?

- Answer: Yes. Explosion-proof (ATEX Zone 21/22, IECEx) versions are available with reinforced construction, anti-static filter media, and fail-safe venting per EN 1127.

- Q7. What warranty and support does the manufacturer provide?

- Answer: Standard warranty: 24 months. Optional extended warranty up to 5 years available. Remote/on-site technical support, spare parts kits, and cloud-based monitoring are provided.

10. Delivery Lead Time, Quality Commitment & After-Sales

- Lead Time: Standard models ship in 20–30 working days; custom engineered systems, 45–60 working days.

- Warranty: 2-Year full system warranty, extendable to 5 years (optional), covering all manufacturing defects, material failures, and premature filter wear.

- Quality Assurance: 100% QC check with digital QA record, ISO 9001 traceability, pre-shipment test run video/inspection available to clients.

- After-Sales Support: 24/7 technical hotline, local language support in 8+ languages, remote diagnostic access, and spare parts logistics in 28 countries.

- Customer Confidence: Served 700+ clients across 32 countries since 2010.

"Our experience with the High Efficiency Manufacturer Supplies Dust Collector has been exceptional. The commissioning support and energy savings exceeded our expectations."

—Process Safety Officer, European Petrochemical Group

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: