Tel:

+8615930870079

Tel:

+8615930870079

Aug . 16, 2024 22:39 Back to list

High Efficiency Cartridge Filter for Dust Extraction and Air Filtration

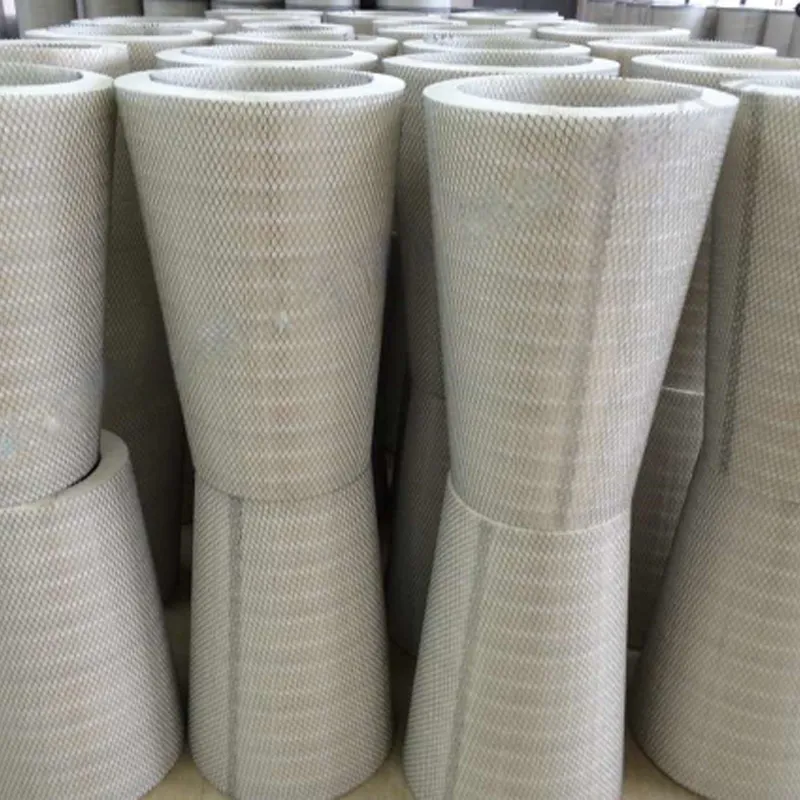

Fine Cartridge Filters for Dust Extractors Enhancing Air Quality and Efficiency

In today's industrial landscape, maintaining a clean and safe working environment is paramount. One of the key components to achieving this is the effective capture and removal of airborne dust and particulate matter. Fine cartridge filters for dust extractors play a vital role in ensuring that harmful particles are efficiently removed from the air, thus protecting both workers and equipment. This article explores the significance, functionality, and benefits of fine cartridge filters in dust extraction systems.

Understanding Fine Cartridge Filters

Fine cartridge filters are specially designed filtration devices used in dust extraction systems to capture very small particles that would otherwise escape less efficient filters. They typically consist of a cylindrical filter media that is made from materials such as polyester, polypropylene, or other synthetic fibers. The structure of these cartridges allows for high filtration efficiency while maintaining a lower pressure drop, which is critical for the efficient operation of dust extractors.

How Do Fine Cartridge Filters Work?

When air laden with dust passes through a dust extractor equipped with fine cartridge filters, the filter media captures particles through several mechanisms, including mechanical filtration, electrostatic attraction, and diffusion. As the contaminated air enters the filter, larger particles are trapped on the surface, while smaller particles continue deeper into the filter structure. This layered approach ensures that even very fine particulates, which can pose serious health risks, are effectively removed from the air.

One of the key advantages of using fine cartridge filters is their ability to be cleaned and reused. Most dust extractors are equipped with an automatic pulse cleaning system that reverses the airflow at regular intervals, dislodging collected dust and debris from the filter surface. This not only extends the life of the filter but also maintains optimal airflow and filtration efficiency over time.

Advantages of Fine Cartridge Filters

fine cartridge filter for dust extractor

1. Enhanced Air Quality Fine cartridge filters are capable of trapping particles as small as 0.3 microns, including harmful substances such as silica dust, wood dust, and metal shavings. By effectively removing these particles from the air, they help to improve indoor air quality, which is crucial for the health and productivity of workers.

2. Cost-Effectiveness The longevity and reusability of fine cartridge filters contribute to long-term cost savings for businesses. With reduced replacement frequency and maintenance needs, companies can allocate resources more efficiently and focus on their core operations.

3. Versatility Fine cartridge filters are suitable for a wide range of applications across various industries, including manufacturing, woodworking, food processing, and pharmaceuticals. Their adaptability makes them a preferred choice for many businesses seeking effective dust control solutions.

4. Compliance with Regulations Many industries are subject to strict air quality regulations. Utilizing fine cartridge filters helps companies comply with these standards, reducing the risk of fines and enhancing their reputation as responsible employers.

5. Increased Equipment Lifespan By capturing dust and debris before they can accumulate in machinery, fine cartridge filters help protect equipment from wear and tear, ultimately extending its lifespan and reducing maintenance costs.

Conclusion

Fine cartridge filters are indispensable components of modern dust extraction systems, providing numerous benefits for both the workplace and the environment. By enhancing air quality, reducing operational costs, and ensuring compliance with regulations, these filters contribute significantly to maintaining a safe and efficient working atmosphere. As industries continue to prioritize employee health and environmental responsibility, the role of fine cartridge filters in dust extraction will only become more critical.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: