Tel:

+8615930870079

Tel:

+8615930870079

Dec . 02, 2024 07:23 Back to list

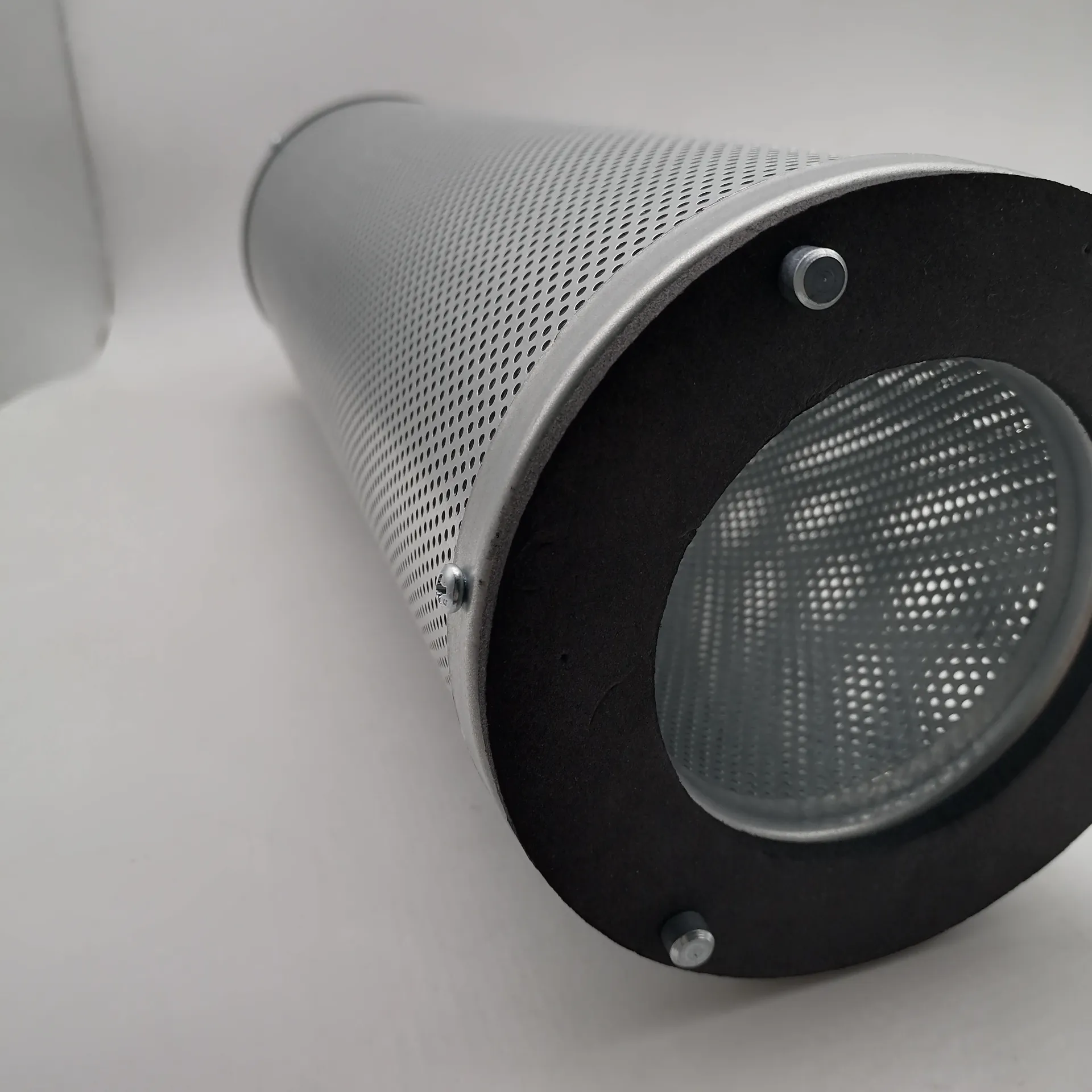

gas turbine air intake filter manufacturers

The Importance of Gas Turbine Air Intake Filters Manufacturers' Insights

Gas turbines are a crucial component of modern power generation, driving both electrical and mechanical systems across various industries. The efficiency and longevity of these turbines largely depend on the cleanliness of the air they ingest. This makes air intake filters a vital component in the gas turbine system, as they protect the turbine's components from contaminants that can lead to reduced performance and operational issues. This article explores the role of gas turbine air intake filters and highlights leading manufacturers in this field.

Understanding Gas Turbine Air Intake Filters

Air intake filters for gas turbines serve the critical purpose of removing particulates, dust, and other harmful substances from the air before it enters the turbine. Contaminants in the intake air can impair the efficiency of combustion, lead to excessive wear on turbine blades, and ultimately result in costly downtime and maintenance. Therefore, high-quality filters are essential for optimal turbine operation and reliability.

The filters work by using various technologies, such as fiberglass, synthetic media, or pleated designs, to maximize airflow while minimizing resistance. Engineers and maintenance teams must select filters appropriate for the operating environment, taking into account aspects like humidity, temperature, and the presence of corrosive elements.

Key Manufacturers of Gas Turbine Air Intake Filters

Several manufacturers specialize in producing high-quality air intake filters for gas turbines. Their products are designed to meet specific industry standards and are often subjected to rigorous testing to ensure they can withstand challenging operating conditions.

gas turbine air intake filter manufacturers

1. Donaldson Company, Inc. Donaldson is a global leader in filtration technology, providing solutions for air, gas, and liquid filtration. Their line of air intake filters is engineered to enhance the reliability and performance of gas turbines, ensuring that only clean air reaches the engine. Utilizing advanced filtration media, Donaldson filters can capture fine particulates while maintaining optimal airflow.

2. Parker Hannifin Parker Hannifin specializes in motion and control technologies, including filtration systems for gas turbines. Their air intake filters are designed with durability in mind, offering excellent protection against contamination. Parker's commitment to innovation has led to the development of filters that improve engine efficiency while minimizing maintenance costs.

3. Camfil With a strong focus on sustainability, Camfil offers a range of air filtration solutions, including specialized filters for gas turbines. Their products are designed to enhance air quality and improve turbine performance while reducing energy consumption. Camfil's filters are particularly known for their effectiveness in extreme operating environments.

4. Aaf International Aaf International is renowned for its air filtration products, serving various industries, including power generation. The company's gas turbine air intake filters are meticulously designed to capture airborne contaminants while also being easy to replace. Aaf International’s focus on research and development ensures that their filtration solutions remain at the forefront of technology.

5. Mann+Hummel Mann+Hummel is a global leader in filtration and separation technology, providing advanced solutions for gas turbines. Their intake filters are designed to meet the rigorous demands of the power generation sector, ensuring long service life and efficient airflow. Mann+Hummel invests heavily in R&D to continuously enhance the performance and sustainability of their products.

Conclusion

As the demand for efficient energy production continues to grow, the importance of high-quality air intake filters for gas turbines becomes increasingly evident. Leading manufacturers like Donaldson, Parker Hannifin, Camfil, Aaf International, and Mann+Hummel are committed to developing innovative filtration solutions that enhance turbine performance and operational efficiency. By investing in advanced air intake filters, power generation companies can ensure the longevity and reliability of their gas turbines, ultimately leading to improved energy production and reduced operational costs.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: