Tel:

+8615930870079

Tel:

+8615930870079

Nov . 27, 2024 09:55 Back to list

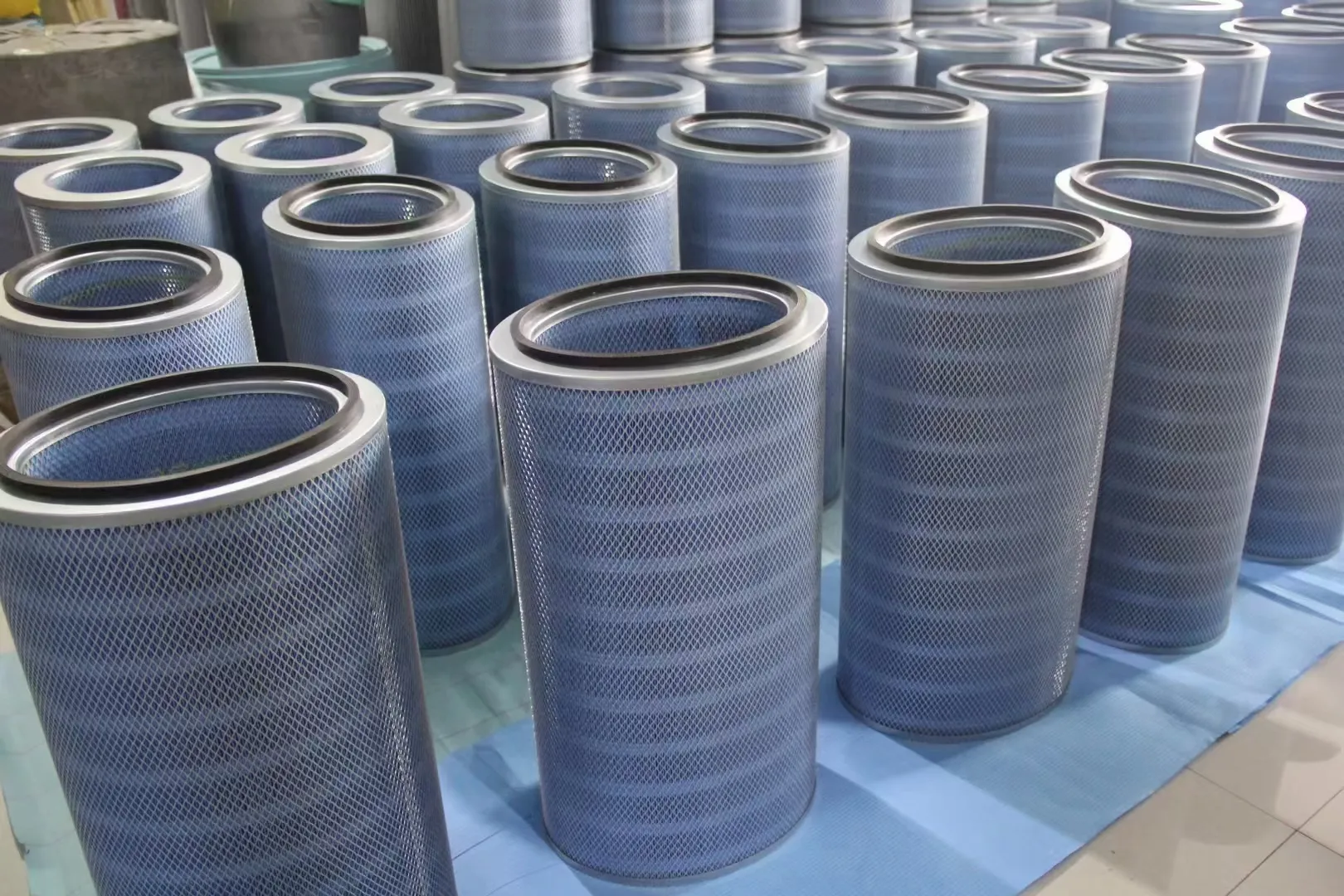

Air Intake Filter Suppliers for Gas Turbines and Their Innovations

The Importance of Gas Turbine Air Intake Filter Manufacturers in Power Generation

Gas turbines have become a cornerstone of modern power generation, known for their efficiency and reliability. At the heart of their operation lies a crucial component the air intake filter system. The performance and longevity of gas turbines heavily depend on high-quality air intake filters, highlighting the importance of manufacturers in this field.

What Are Gas Turbine Air Intake Filters?

Gas turbine air intake filters are designed to ensure that the air entering the turbine is clean and free from contaminants. These filters play a vital role in protecting the turbine components from airborne particles such as dust, dirt, and microorganisms. By providing a clean air supply, these filters help maintain optimal engine performance and extend the lifespan of the equipment.

The Role of Manufacturers

Manufacturers of gas turbine air intake filters are responsible for producing filters that meet high industry standards. They engage in rigorous research and development to design filters that offer maximum efficiency in trapping particles while allowing for sufficient airflow. Quality manufacturers utilize advanced materials and innovative engineering techniques to create filters that perform under extreme conditions commonly experienced in power generation environments.

1. Material Selection The materials used in the construction of air intake filters are critical for their performance. Manufacturers often use synthetic fibers or advanced composites that combine durability with lightweight properties, ensuring that filters can effectively capture contaminants without adding excessive weight to the system.

2. Filter Design Several design aspects contribute to the effectiveness of air intake filters. Leading manufacturers focus on constructing filters with optimal surface area, pleating designs, and varying porosity to ensure enhanced dirt-holding capacity and minimal pressure drop. The goal is to achieve a balance between airflow and filtration efficiency.

3. Testing and Quality Assurance Reputable manufacturers adhere to strict testing protocols, ensuring that their filters meet or exceed the set regulatory standards. Through comprehensive testing, manufacturers can ascertain the efficiency, endurance, and performance of their filters, proving their reliability for gas turbine operation.

gas turbine air intake filter manufacturers

4. Customization and Adaptability Each gas turbine system may have unique requirements based on operational conditions and environmental factors. Leading manufacturers offer customization options, allowing clients to obtain filters specifically tailored to their needs. This adaptability is essential for optimizing the performance of gas turbines across different geographical and atmospheric conditions.

The Impact of Quality Filters on Performance

The quality of air intake filters directly affects the efficiency and operational longevity of gas turbines. High-quality filters not only enhance performance but also result in cost savings over time. They reduce the need for maintenance and decrease the likelihood of unexpected downtime due to equipment failure. Furthermore, improved air filtration can lead to better fuel efficiency and lower emissions, contributing to more sustainable power generation practices.

Future Trends in Filter Manufacturing

As the energy sector continues to evolve, manufacturers of gas turbine air intake filters are expected to face new challenges and opportunities. The growing emphasis on environmental sustainability and the reduction of carbon footprints is shaping the development of advanced filtration technologies. Manufacturers are increasingly investing in state-of-the-art materials and eco-friendly processes to meet the rising demand for sustainable solutions.

Additionally, the integration of digital technologies into manufacturing processes is expected to enhance quality control and efficiency. Smart filters equipped with sensors that monitor air quality and filter performance in real-time could soon become a reality. These innovations will provide operators with actionable insights, enabling them to optimize filter maintenance schedules and ensure the continued reliability of gas turbines.

Conclusion

Gas turbine air intake filter manufacturers play a vital role in the broader context of power generation. Their commitment to quality and innovation ensures that the energy sector can rely on efficient, clean, and sustainable power sources. By recognizing the critical role of these manufacturers, stakeholders can make informed decisions that contribute to the longevity and performance of gas turbines, ultimately leading to a more reliable energy future.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: