Tel:

+8615930870079

Tel:

+8615930870079

Nov . 27, 2024 05:35 Back to list

Optimization of Air Intake Filters for Gas Turbine Performance Enhancement

The Significance of Gas Turbine Air Intake Filters

Gas turbines are essential components in the energy and aviation industries, generating power and enabling aircraft propulsion. Their efficiency and performance heavily depend on the quality of the air entering the engine. Consequently, the air intake filter plays a critical role in ensuring optimal operation. This article explores the importance of air intake filters for gas turbines, focusing on their functions, types, maintenance, and impact on overall performance.

Functions of Air Intake Filters

The primary function of gas turbine air intake filters is to prevent contaminants such as dust, dirt, pollen, and other particulate matter from entering the turbine. These impurities can cause significant damage to the turbine's internal components over time. By trapping such particles, filters help maintain the cleanliness of engine components, leading to improved efficiency and reliability.

Additionally, air filters can help in moisture control. In some environments, humidity can lead to corrosion and other issues within the turbine. Advanced filters are designed to manage moisture levels, ensuring that only clean, dry air enters the turbine system.

Types of Air Intake Filters

There are several types of air intake filters used in gas turbines, each with distinct characteristics suited for different operational environments

. The most common types include1. Panel Filters These are widely used due to their ease of replacement and maintenance. Panel filters typically consist of several layers of fine mesh, trapping various particle sizes effectively.

2. Bag Filters These filters are designed to offer a larger surface area, which enhances their dirt-holding capacity. Their design allows for the filtration of larger particles, making them ideal for dusty environments.

3. Cyclone Filters Employing centrifugal force, cyclone filters remove larger particles from the air before it reaches the main filtration system. This pre-filtering process reduces the load on the primary filter, extending its life.

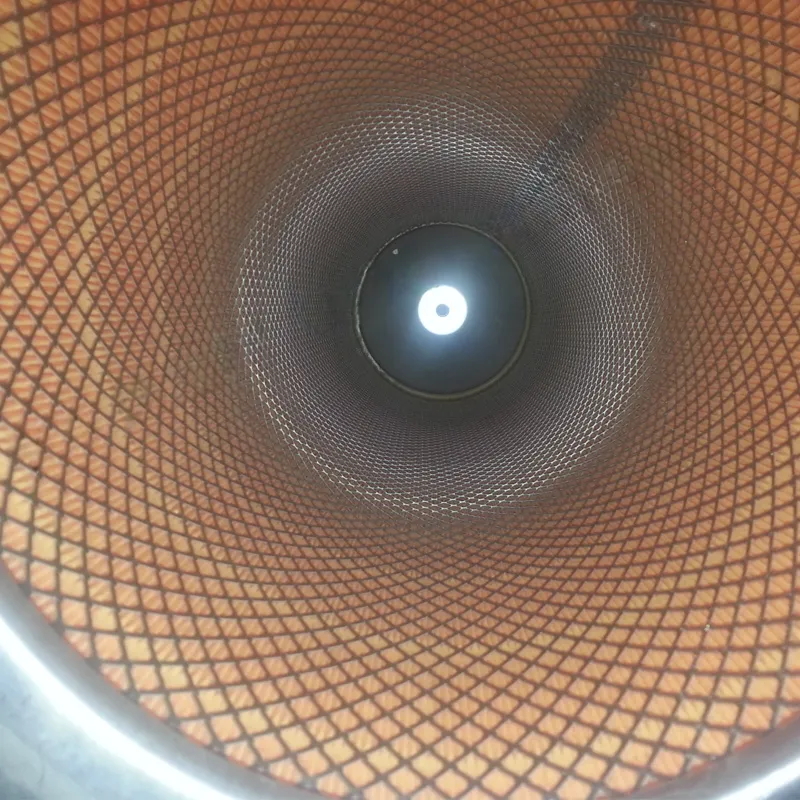

gas turbine air intake filter

4. Electrostatic Filters Utilizing electrostatic charge, these filters attract and capture charged particles, providing efficient filtration for fine dust and other microscopic contaminants.

Each of these filters is designed to meet specific operational needs, and the choice of filter can significantly affect the efficiency and longevity of the turbine.

Maintenance of Air Intake Filters

Regular maintenance of air intake filters is crucial for maximizing their effectiveness and ensuring the optimal performance of gas turbines. Depending on the operational environment, filters may require periodic inspections and replacements. In dusty or polluted areas, for instance, filters can become clogged more rapidly, necessitating more frequent changes.

Maintenance should include a thorough inspection for signs of wear and tear, checking for blockages, and validating that the filter's sealing mechanisms are intact to avoid unfiltered air entry. Many modern filtration systems are designed with indicators that alert operators when a filter change is necessary, thus simplifying maintenance procedures.

Impact on Performance

The performance of gas turbines is directly tied to the quality of air entering the system. Clean air leads to more efficient combustion, resulting in higher power output and reduced fuel consumption. Conversely, dirty or contaminated air can lead to decreased efficiency, increased emissions, and potentially costly repairs.

Furthermore, the longevity of the turbine can be affected by the condition of the air filters. A well-maintained air intake filter can significantly extend the operational life of the turbine by minimizing wear caused by particulate ingress. This not only reduces repair costs but also enhances overall system reliability.

Conclusion

In summary, the air intake filter is a vital component of gas turbine systems. Its primary function of filtering out contaminants not only protects critical engine components but also ensures optimal performance and efficiency. Recognizing the importance of air intake filters and prioritizing their maintenance can lead to enhanced turbine longevity and reliability, ultimately resulting in significant operational cost savings. As industries continue to demand higher efficiency and lower emissions, the role of air intake filters will remain paramount in the functioning of gas turbines.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: