Tel:

+8615930870079

Tel:

+8615930870079

Nov . 16, 2024 10:54 Back to list

Air Filter Systems for Gas Turbine Performance Enhancement and Maintenance Solutions

The Importance of Air Intake Filters in Gas Turbine Operations

Gas turbines are essential components in various industries, including power generation, aviation, and marine propulsion. Their efficiency and reliability depend significantly on the quality of the air they intake. An often overlooked but critical component that ensures optimal performance of gas turbines is the air intake filter. This article discusses the role of air intake filters in gas turbine operations, emphasizing their importance in maintaining engine performance and longevity.

The Importance of Air Intake Filters in Gas Turbine Operations

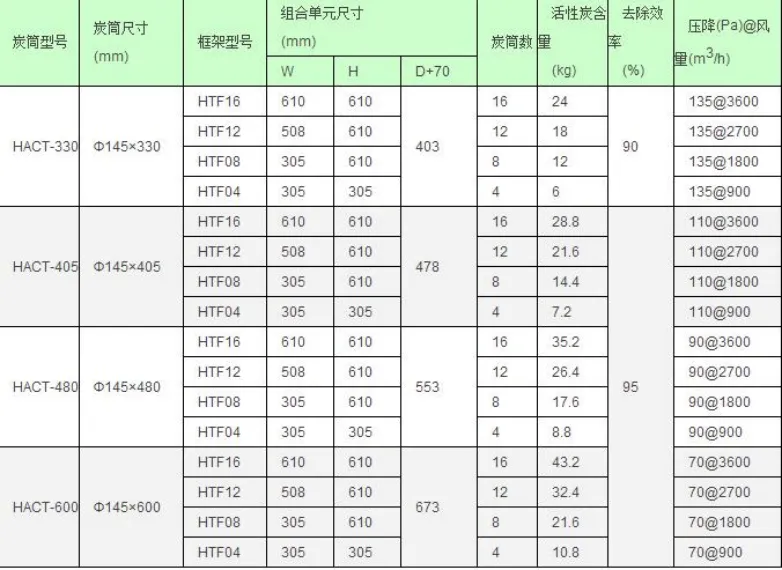

There are various types of air intake filters used in gas turbines, including panel filters, bag filters, and cartridge filters. Each type has its unique advantages and is chosen based on specific operational requirements. For instance, panel filters are often used for their ease of installation and replacement, while bag filters are more efficient for higher dust loading applications. Cartridge filters, on the other hand, provide a high surface area for filtration, which allows them to capture more particulate matter while maintaining airflow.

gas turbine air intake filter

Regular maintenance and replacement of these filters are crucial for ensuring the longevity and efficiency of gas turbines. Over time, filters can become clogged with dirt and dust, which restricts airflow and forces the turbine to work harder. This increased load can lead to excessive fuel consumption and higher emissions, further emphasizing the need for effective filtration. Monitoring air pressure differentials across filters can help operators determine when a filter needs maintenance, thus avoiding costly downtime.

Moreover, advancements in filter technology have led to the development of more efficient filtration materials, such as synthetic fibers. These modern filters not only provide enhanced dirt-holding capacity but also improve airflow, which is critical for the performance of gas turbines. In addition, some filters are designed with moisture resistance properties, which is particularly beneficial in humid environments where moisture can impact filtration efficiency.

In conclusion, air intake filters are vital for the reliable and efficient operation of gas turbines. By preventing contaminants from entering the engine, these filters protect components, enhance performance, and extend the lifespan of the turbine. As industries continue to strive for improved efficiency and reduced environmental impact, the selection and maintenance of appropriate air intake filters will play an increasingly important role in the optimal functioning of gas turbines. Regular attention to this essential component is not just best practice; it is a crucial investment in the operational success of gas turbine systems.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: