Tel:

+8615930870079

Tel:

+8615930870079

Oct . 22, 2024 12:38 Back to list

Enhancing Gas Turbine Performance Through Effective Air Intake Filtration Solutions

Gas Turbine Air Intake Filters A Critical Component for Efficiency and Longevity

Gas turbines are essential in various applications, including power generation, aviation, and marine propulsion. One critical component that ensures their efficiency and durability is the air intake filter. These filters play a vital role in protecting the engine from contaminants, maintaining performance, and optimizing fuel efficiency.

Understanding Gas Turbine Air Intake Systems

At the heart of a gas turbine's operation is the combustion of fuel, which requires a continuous supply of clean air. The air intake system is designed to draw in ambient air, compress it, mix it with fuel, and ignite the mixture to produce thrust or generate electricity. However, this process is vulnerable to contamination from particulate matter, dust, pollen, and other environmental pollutants. This is where air intake filters come into play.

The Role of Air Intake Filters

Air intake filters serve to capture and remove contaminants before they enter the combustion chamber. By maintaining a clean airflow, these filters help ensure optimal combustion efficiency, reduce emissions, and enhance overall turbine performance. There are several key functions of air intake filters

1. Contaminant Removal Filters effectively capture dirt, dust, and other particles that could damage turbine components, such as compressor blades and combustion systems. By preventing these contaminants from entering the engine, filters help to prolong the lifespan of critical components.

2. Optimizing Airflow A well-designed filter does not obstruct airflow. Instead, it allows for a steady and unobstructed intake of air, which is essential for maintaining the right fuel-to-air ratio for combustion. Any restriction in airflow can lead to reduced efficiency and performance.

3. Heat Management Filters can also play a role in managing the temperature of the incoming air. By controlling how much heat enters the turbine, filters can help optimize the combustion process and improve overall engine performance.

Types of Air Intake Filters

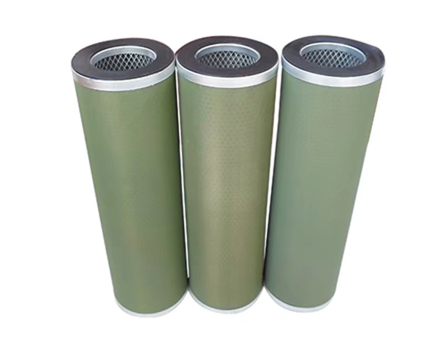

gas turbine air intake filter

There are several types of air intake filters used in gas turbines, each with its unique features and benefits

1. Foam Filters These filters are made from porous foam material that captures particles while allowing air to flow freely. They are reusable and can be washed and re-oiled, making them a cost-effective option.

2. Wet Filters These filters are treated with a liquid that traps dust and debris. They are highly effective but require regular maintenance to ensure they remain operational.

3. Dry Filters Dry filters use a layer of treated paper or synthetic material to trap airborne particles. They are disposable and must be replaced periodically, which can be more convenient but may incur additional costs.

4. Cyclonic Filters These advanced filters use centrifugal force to separate particles from the airflow. They can handle larger volumes of air and are often used in industrial applications.

Maintenance and Best Practices

To ensure the longevity and efficiency of gas turbine air intake filters, regular maintenance is essential. Filters should be inspected frequently for clogging or damage. Depending on the type of filter, cleaning or replacement schedules will vary. Monitoring pressure drop across the filter can also indicate when maintenance is necessary; an increase in pressure drop typically signals that the filter is becoming clogged.

Additionally, it is essential to select the right filter for the specific application. Factors such as ambient environmental conditions, expected load, and operational settings should guide filter selection. Using filters that meet or exceed manufacturer specifications ensures optimal performance and protection.

Conclusion

In summary, gas turbine air intake filters are crucial for maintaining the integrity and performance of gas turbines. By effectively removing contaminants from the air supply, optimizing airflow, and contributing to efficient combustion, these filters play a vital role in the overall system. Regular maintenance and the proper selection of filters are essential to ensure that gas turbines operate efficiently and sustainably, bridging the gap between energy demands and environmental stewardship. Recognizing their importance can lead to significant improvements in both operational efficiency and the longevity of gas turbine systems.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: