Tel:

+8615930870079

Tel:

+8615930870079

Oct . 11, 2024 07:57 Back to list

Improving Air Quality in Gas Turbine Intake Systems with Advanced Filtration Techniques

Understanding Gas Turbine Air Intake Filters

Gas turbines are critical components in power generation and aviation, known for their efficiency and reliability. However, their performance can be significantly affected by the quality of air intake. This is where air intake filters come into play. These filters are essential in ensuring that only clean air enters the gas turbine, which directly impacts its performance, longevity, and overall efficiency.

The Importance of Air Quality

Air quality is paramount for gas turbines. These turbines operate on the principle of compressing air, mixing it with fuel, and igniting the mixture to produce energy. Any impurities—such as dust, dirt, and other particulate matter—can adversely affect the turbine's components, leading to increased maintenance costs and potentially catastrophic failures. The debris can erode blade surfaces, clog combustion chambers, and reduce the overall thermal efficiency of the turbine.

Types of Air Intake Filters

There are various types of air intake filters used in gas turbines, each designed to capture different sizes of particles and meet specific operational requirements.

1. Panel Filters These are the most common type of air filters. They are usually made from fiberglass or synthetic materials and are designed to capture larger particles. Panel filters are often used as pre-filters to extend the life of more sophisticated filters.

2. Bag Filters Bag filters consist of multiple fabric bags that capture smaller particles. They provide a larger surface area than panel filters, which can result in lower pressure drops and longer service life, particularly in environments with high particulate loads.

3. High-Efficiency Particulate Air (HEPA) Filters For applications requiring very high air quality, HEPA filters are critical. They can capture up to 99.97% of particles that are 0.3 microns or larger. While they are more expensive and may require more frequent replacements, the protection they provide can be invaluable in high-stakes environments.

4. Pre-Filters Used in combination with more sophisticated filters, pre-filters serve to extend the lifespan of primary filters by capturing larger particles, which can dramatically improve air quality and reduce operational costs.

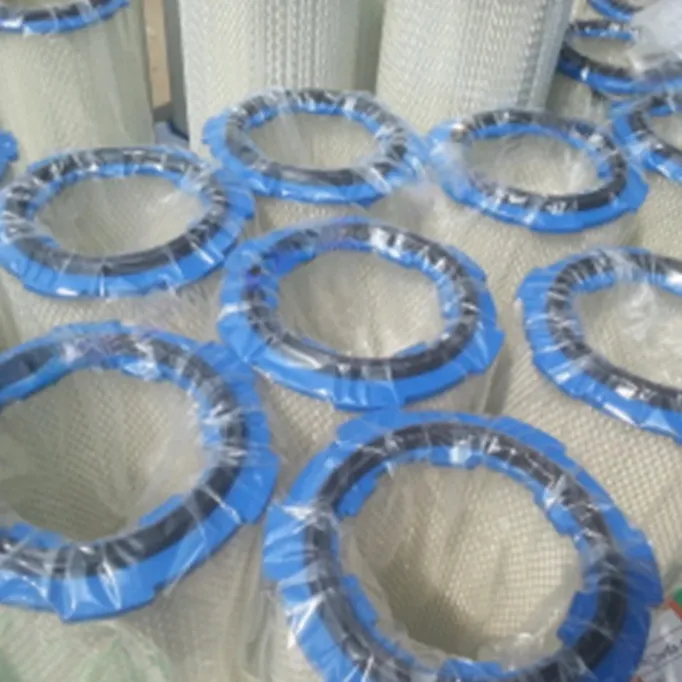

gas turbine air intake filter

Selection Criteria for Air Intake Filters

When selecting an air intake filter for a gas turbine, several factors must be considered

- Particle Size Understanding the types of contaminants present in the environment is essential for choosing the right filter. This includes considering both the size and concentration of particles.

- Airflow Requirements The filter should be designed to accommodate the required airflow without causing excessive pressure drops. A filter that restricts airflow can significantly impede turbine performance.

- Operating Environment Conditions such as humidity, temperature extremes, and the presence of oils or chemicals can all affect filter performance and longevity.

- Maintenance and Replacement Intervals Filters with longer service lives can reduce maintenance frequency and associated costs. However, they may also come at a higher initial cost.

Impact on Gas Turbine Performance

The role of air intake filters transcends mere filtration; they are integral to the overall efficiency of gas turbines. A clean air intake leads to optimal combustion, improved thermal efficiency, and reduced emissions. Moreover, maintaining proper air quality through effective filtration minimizes wear and tear on the turbine components and can substantially enhance the lifespan of the equipment.

Conclusion

In conclusion, the significance of air intake filters in gas turbine operations cannot be understated. These filters ensure the turbine receives clean, contaminant-free air, which is crucial for maintaining performance and reliability. With different types of filters available, the selection process must be guided by specific operational needs and environmental conditions. Ultimately, investing in high-quality air intake filters is not just a matter of performance; it's about safeguarding the integrity and efficiency of one of the most critical systems in our modern infrastructure.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: