ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Feb . 06, 2025 05:27 Back to list

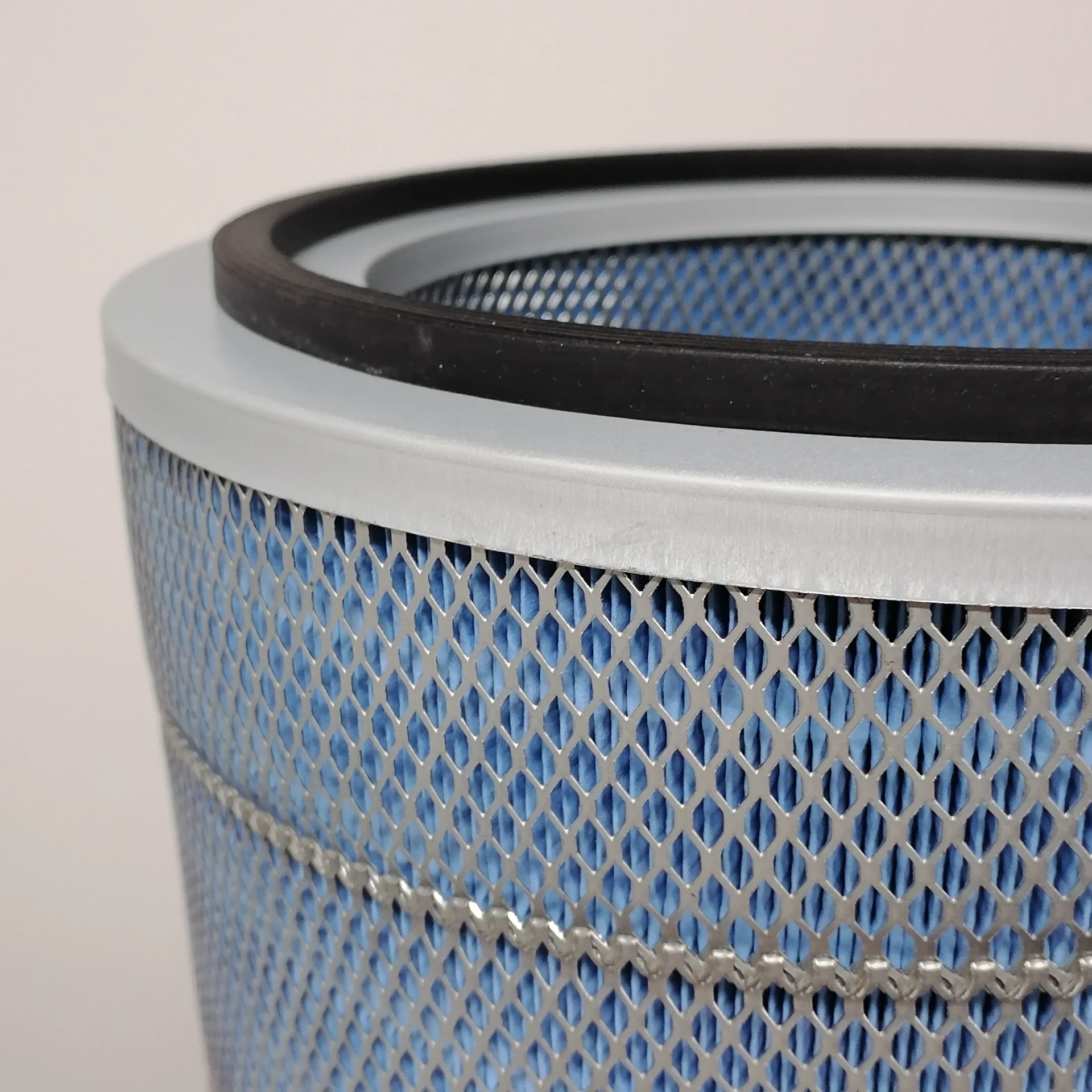

Gas Turbine Intake Filter

Maximizing the Efficiency and Longevity of Gas Turbine Air Intake Filters

Authoritative studies indicate that a regular maintenance schedule for air intake filters can prevent undue stress on turbine components. Filters should be inspected and replaced based on pressure drop measurements rather than a fixed timetable to prevent either premature changes or operational inefficiency due to clogged filters. Implementing a condition-based maintenance strategy, informed by pressure differential and environmental monitoring, optimizes both performance and cost-efficiency. Trustworthiness in filter selection is paramount, as inferior products can lead to catastrophic failures. Thus, collaboration with reputable manufacturers who provide detailed filter performance data and adhere to industry standards such as ISO 29461-1 for air intake filter systems is essential. Ensuring that products are certified by credible testing bodies adds an extra layer of assurance that the filters will perform as expected under a range of conditions. Real-world applications reveal intriguing insights into filter performance. For example, a power generation facility located in an area with high seasonal pollen counts implemented a two-stage filtration system combining both coarse and fine filters. This configuration not only extended the primary filter's life by preventing rapid clogging but also maintained optimal turbine efficiency during peak pollen seasons. Another case study from an industrial setting underscores how filter upgrades led to noticeable improvements in turbine efficiency and reduced operational costs. By switching to filters with enhanced nano-fiber technology, the plant observed a reduction in pressure drop, translating to lower energy consumption and emissions. In conclusion, the strategic selection and maintenance of gas turbine air intake filters are indispensable to achieving optimal turbine efficiency and reliability. By emphasizing expertise in filter attributes, adopting authoritative maintenance practices, and fostering trust in filter quality through partnership with esteemed manufacturers, an organization can significantly enhance both the performance and longevity of its turbine systems. Industry professionals keen on cutting-edge performance improvements must consistently evaluate and iterate on their filtration strategies, aligning them closely with environmental dynamics and operational demands. An informed and proactive approach will ensure that gas turbine systems remain robust and efficient in an ever-evolving operational landscape.

Authoritative studies indicate that a regular maintenance schedule for air intake filters can prevent undue stress on turbine components. Filters should be inspected and replaced based on pressure drop measurements rather than a fixed timetable to prevent either premature changes or operational inefficiency due to clogged filters. Implementing a condition-based maintenance strategy, informed by pressure differential and environmental monitoring, optimizes both performance and cost-efficiency. Trustworthiness in filter selection is paramount, as inferior products can lead to catastrophic failures. Thus, collaboration with reputable manufacturers who provide detailed filter performance data and adhere to industry standards such as ISO 29461-1 for air intake filter systems is essential. Ensuring that products are certified by credible testing bodies adds an extra layer of assurance that the filters will perform as expected under a range of conditions. Real-world applications reveal intriguing insights into filter performance. For example, a power generation facility located in an area with high seasonal pollen counts implemented a two-stage filtration system combining both coarse and fine filters. This configuration not only extended the primary filter's life by preventing rapid clogging but also maintained optimal turbine efficiency during peak pollen seasons. Another case study from an industrial setting underscores how filter upgrades led to noticeable improvements in turbine efficiency and reduced operational costs. By switching to filters with enhanced nano-fiber technology, the plant observed a reduction in pressure drop, translating to lower energy consumption and emissions. In conclusion, the strategic selection and maintenance of gas turbine air intake filters are indispensable to achieving optimal turbine efficiency and reliability. By emphasizing expertise in filter attributes, adopting authoritative maintenance practices, and fostering trust in filter quality through partnership with esteemed manufacturers, an organization can significantly enhance both the performance and longevity of its turbine systems. Industry professionals keen on cutting-edge performance improvements must consistently evaluate and iterate on their filtration strategies, aligning them closely with environmental dynamics and operational demands. An informed and proactive approach will ensure that gas turbine systems remain robust and efficient in an ever-evolving operational landscape.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: