ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Feb . 03, 2025 01:07 Back to list

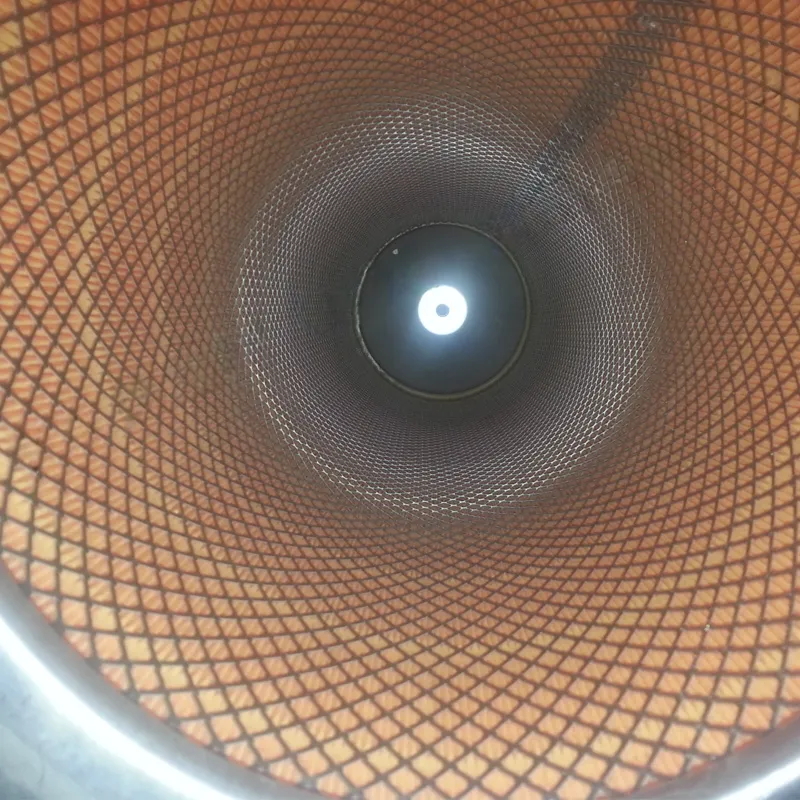

gas turbine air intake filter

Gas turbine air intake filters stand at the forefront of efficient turbine operation, safeguarding the intricate systems within while enhancing overall performance. It's imperative to delve into their significance, leveraging years of expertise and addressing the pressing need for reliability and efficiency in modern industrial applications.

Authoritativeness in the realm of gas turbine filters cannot be understated. Leading manufacturers and industry bodies have set stringent standards that these filters must meet. Compliance with standards such as ISO 29461 ensures that filters can withstand the tough demands of varying operational contexts. Trusted names in the industry back their products with extensive research and development data, affirming their reliability. Partnering with reputable manufacturers not only ensures quality products but also provides access to a wealth of knowledge in optimizing turbine systems. Trustworthiness is equally crucial, especially considering the potential ramifications of subpar performance. Customers and engineers need assurance that the selected filters will perform under all specified conditions. Transparency from producers regarding filter specifications, longevity, and efficacy, coupled with rigorous third-party testing, helps build this trust. In practice, this means offering comprehensive data sheets and case studies for potential buyers to scrutinize. Investing in gas turbine air intake filters is not just about immediate operational gains. It is a strategic decision impacting long-term maintenance schedules and financial forecasting. As operational efficiencies increase, so too does the return on investment, freeing resources for innovation and expansion. Extended filter life cycles also mean reduced downtime and maintenance labor, adding another layer of financial attractiveness. In conclusion, the gas turbine air intake filter is more than a mere component; it is an integral element that intertwines with the technological, environmental, and economic spheres of industrial operation. By emphasizing experience, leveraging expertise, aligning with authoritative standards, and fostering trust through transparency, industries can optimize their turbine operations. Always remember the clearer the air that fuels the turbine, the more powerful and efficient the engine driving industrial progress.

Authoritativeness in the realm of gas turbine filters cannot be understated. Leading manufacturers and industry bodies have set stringent standards that these filters must meet. Compliance with standards such as ISO 29461 ensures that filters can withstand the tough demands of varying operational contexts. Trusted names in the industry back their products with extensive research and development data, affirming their reliability. Partnering with reputable manufacturers not only ensures quality products but also provides access to a wealth of knowledge in optimizing turbine systems. Trustworthiness is equally crucial, especially considering the potential ramifications of subpar performance. Customers and engineers need assurance that the selected filters will perform under all specified conditions. Transparency from producers regarding filter specifications, longevity, and efficacy, coupled with rigorous third-party testing, helps build this trust. In practice, this means offering comprehensive data sheets and case studies for potential buyers to scrutinize. Investing in gas turbine air intake filters is not just about immediate operational gains. It is a strategic decision impacting long-term maintenance schedules and financial forecasting. As operational efficiencies increase, so too does the return on investment, freeing resources for innovation and expansion. Extended filter life cycles also mean reduced downtime and maintenance labor, adding another layer of financial attractiveness. In conclusion, the gas turbine air intake filter is more than a mere component; it is an integral element that intertwines with the technological, environmental, and economic spheres of industrial operation. By emphasizing experience, leveraging expertise, aligning with authoritative standards, and fostering trust through transparency, industries can optimize their turbine operations. Always remember the clearer the air that fuels the turbine, the more powerful and efficient the engine driving industrial progress.

Next:

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: