Tel:

+8615930870079

Tel:

+8615930870079

Sep . 20, 2024 02:09 Back to list

gas turbine air intake filter

The Importance of Air Intake Filters in Gas Turbines

Gas turbines are integral to various industries, including power generation, aviation, and marine propulsion. At the heart of their operation lies a critical component the air intake filter. The efficiency, performance, and longevity of a gas turbine largely depend on the quality of the air it takes in. Thus, understanding the role of air intake filters is essential for optimizing gas turbine operations.

The Importance of Air Intake Filters in Gas Turbines

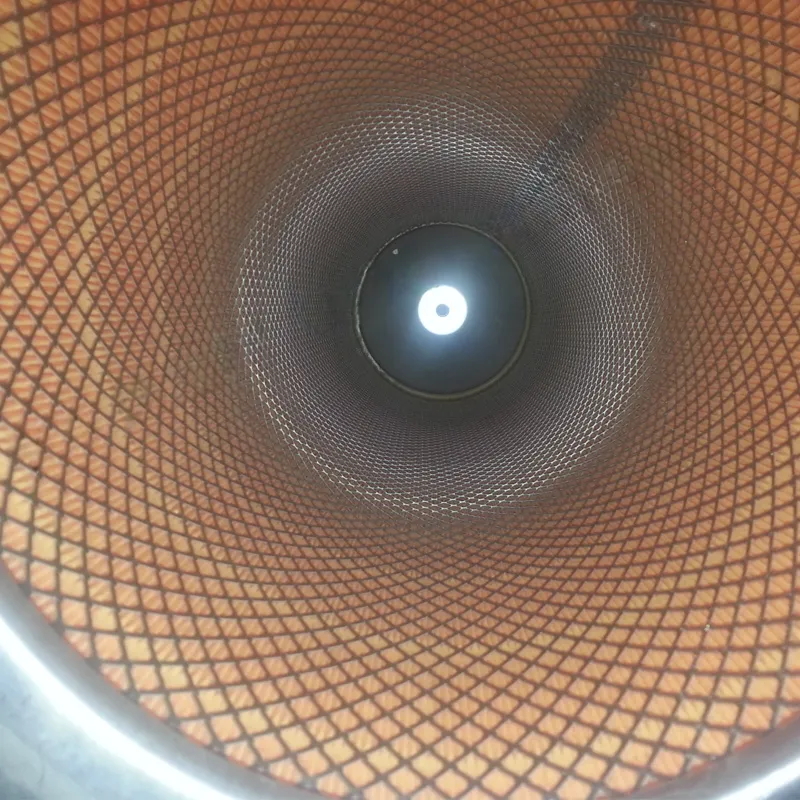

The design of air intake filters has evolved significantly over the years. Modern filters are engineered using advanced materials and technologies to enhance their efficiency and effectiveness. They typically employ multilayered filtration systems that trap varying sizes of particles, ensuring that only clean air enters the turbine. The use of high-efficiency particulate air (HEPA) filters and pleated filter designs helps in maximizing airflow while minimizing pressure drop. This balance is critical, as excessive pressure drop can lead to reduced performance and higher operational costs.

gas turbine air intake filter

Moreover, the maintenance of air intake filters is crucial. Regular inspection and replacement of filters help maintain optimal performance levels. Neglecting air filter maintenance can result in airflow restrictions, increasing the load on the turbine and decreasing its efficiency. In some cases, the accumulation of dirt and debris can lead to a condition known as “dirty air effect,” where the turbine's output power and efficiency drop substantially. To avoid such scenarios, operators often implement scheduled maintenance programs that include the cleaning or replacement of filters at regular intervals.

The location of the gas turbine installation also affects the choice and maintenance of air intake filters. For instance, turbines situated in coastal areas may require filters specifically designed to handle saltwater corrosion and airborne salt particles. Conversely, those installed in industrial regions may need filters capable of managing oily particulates and fine dust. Understanding the environmental conditions in which the turbine operates is essential for selecting the appropriate filter type and implementing an effective maintenance strategy.

In addition to standard filters, some gas turbine applications may benefit from advanced air filtration systems, including electrostatic precipitators and cyclonic separators. These systems can remove a greater volume of particulate matter and enhance the overall efficiency of the air intake process. As technology continues to advance, the future of gas turbine air intake filtration promises even more innovative solutions that will further improve performance and reliability.

In conclusion, air intake filters are an indispensable component of gas turbine systems. They play a vital role in safeguarding the turbine from environmental contaminants, ensuring efficient operation, and prolonging equipment life. By investing in high-quality filters, regular maintenance, and tailored filtration solutions based on environmental conditions, operators can significantly enhance the performance and reliability of their gas turbines. In an era where energy efficiency and sustainability are paramount, the importance of effective air intake filtration in gas turbines cannot be overstated.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: