Tel:

+8615930870079

Tel:

+8615930870079

Nov . 29, 2024 18:39 Back to list

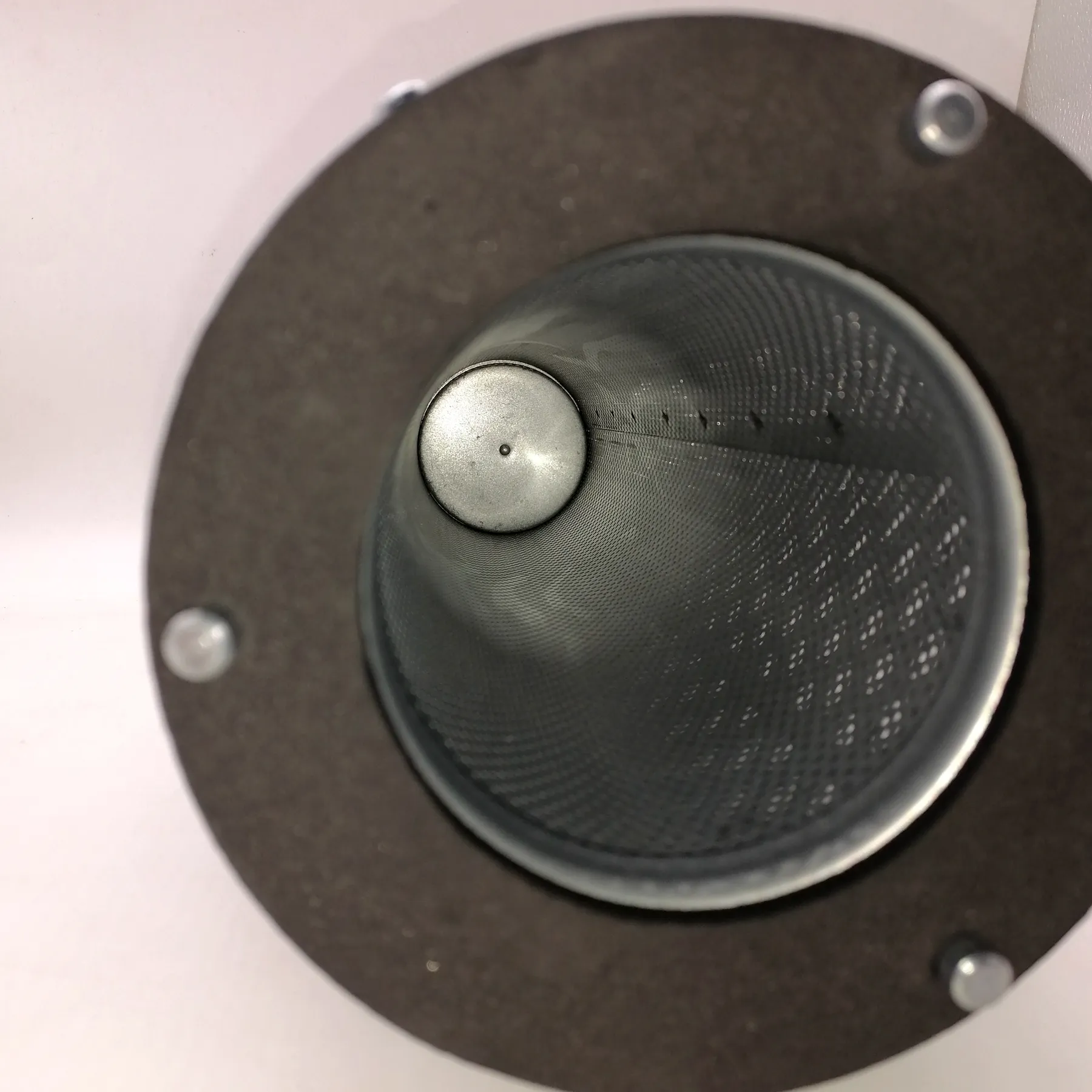

fine cartridge filter for dust extractor

The Importance of Fine Cartridge Filters for Dust Extractors

In various industrial and manufacturing processes, dust generation is a common byproduct. Managing this dust effectively is crucial not only for maintaining a clean and safe working environment but also for ensuring the longevity of machinery and equipment. One of the most effective tools to combat dust in industrial settings is the dust extractor, and at the heart of this equipment is the fine cartridge filter. This article delves into the significance of fine cartridge filters for dust extractors, their operational mechanics, benefits, and best practices for maintenance.

Understanding Fine Cartridge Filters

Fine cartridge filters are specialized filtration devices designed to capture very small particles from the air stream. These filters are typically cylindrical in shape, housing various filter media that trap dust, allergens, and other contaminants. Cartridges are often constructed from synthetic fibers or non-woven fabrics that provide a high surface area for better dust capture efficiency. This design allows them to effectively remove particulates as small as 0.3 microns, which is essential for industries that generate fine dust—such as woodworking, metalworking, pharmaceuticals, and food processing.

How Fine Cartridge Filters Work

The operation of fine cartridge filters is based on several physical principles, including straining, impaction, interception, and diffusion. When dust-laden air is drawn into the filter, larger particles are separated immediately by straining, while smaller particles collide with the filter media and adhere to it through various mechanisms. The layout of pleats and layers within a cartridge maximizes exposure to the air stream, enhancing the overall filtration efficiency. As particles accumulate on the filter surface, the pressure drop across the filter increases, which indicates that it needs to be cleaned or replaced.

Benefits of Using Fine Cartridge Filters

1. High Efficiency Fine cartridge filters offer superior filtration efficiency compared to traditional filters. Their ability to capture microscopic particles ensures cleaner air output, which is essential for compliance with health and safety regulations.

2. Cost-Effective Although fine cartridge filters may have a higher initial cost, their durability and long service life make them a cost-effective choice in the long run. They often require less frequent replacement compared to standard filters.

3. Reduced Downtime The effectiveness of fine cartridge filters means that machinery experiences less contamination, translating to reduced maintenance needs and downtime. This allows for uninterrupted production processes.

4. Versatile Applications Fine cartridge filters can be used in a variety of dust extraction systems and can be tailored for specific applications. This versatility makes them suitable for different industrial environments and dust types.

fine cartridge filter for dust extractor

5. Environmental Compliance Many industries face strict regulations regarding air quality and emissions. Using fine cartridge filters helps companies meet these requirements, thereby avoiding potential fines and promoting a cleaner environment.

Best Practices for Maintenance

To ensure that fine cartridge filters operate at peak efficiency, regular maintenance is crucial. Here are some best practices to consider

- Regular Inspection Routinely inspect filters for signs of wear or damage. This can help identify problems early, preventing costly downtime.

- Cleaning Procedures Most fine cartridge filters are designed to be cleaned using reverse airflow techniques or automated cleaning systems. Follow the manufacturer’s recommendations for cleaning frequency to maintain optimal performance.

- Proper Installation Ensure that filters are installed correctly within the dust extractor. Poor installation can lead to leaks and reduced efficiency.

- Monitoring Pressure Drops Keep an eye on the pressure drop across the filter. Significant increases indicate that the filter is clogged and needs cleaning or replacing.

- Documentation Maintain a log of filter usage, cleaning schedules, and replacement dates to manage maintenance effectively. This can help in planning and budgeting for future costs.

Conclusion

Fine cartridge filters are an indispensable component of dust extractors, playing a vital role in maintaining industrial hygiene and operational efficiency. Their ability to effectively remove fine particles not only enhances the air quality of manufacturing environments but also protects equipment and promotes compliance with regulations. By investing in high-quality fine cartridge filters and adhering to best practices for maintenance, companies can achieve significant improvements in both productivity and safety.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: