Tel:

+8615930870079

Tel:

+8615930870079

Nov . 22, 2024 12:46 Back to list

filter cartridge dust collector

Understanding Filter Cartridge Dust Collectors A Comprehensive Guide

In industries ranging from manufacturing to food production, maintaining a clean and safe working environment is paramount. Dust and other particulate matter can pose serious health risks to employees and negatively affect product quality. One effective solution for managing airborne particles is the filter cartridge dust collector. This article delves into the workings, benefits, and maintenance of filter cartridge dust collectors, highlighting their vital role in industrial air quality management.

What is a Filter Cartridge Dust Collector?

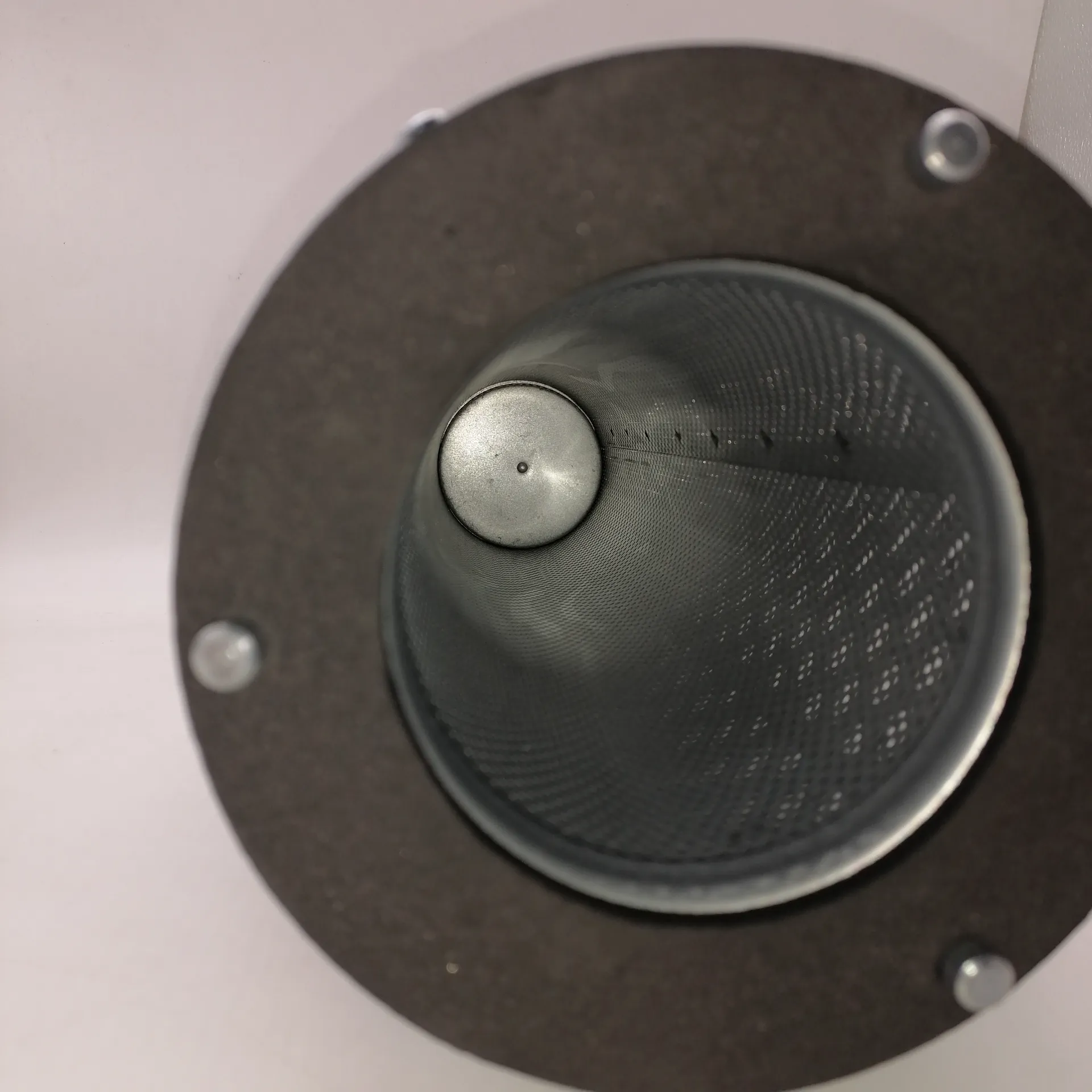

A filter cartridge dust collector is a mechanical device designed to capture and filter airborne dust particles from the air. It utilizes filter cartridges made from various materials that have specific filtration properties to remove contaminants from the air stream. These systems can handle a wide range of dust types, making them versatile for various applications.

The basic operation of a filter cartridge dust collector involves drawing contaminated air into the unit through a fan or blower. As air passes through the filter cartridges, dust particles are trapped on the surface, and clean air is discharged back into the environment. Over time, the accumulated dust needs to be removed from the filter to maintain efficiency.

Key Benefits of Filter Cartridge Dust Collectors

1. High Efficiency Filter cartridge dust collectors can achieve high filtration efficiencies, often exceeding 99% in capturing airborne particles. This high performance ensures a cleaner work environment and reduces potential health hazards associated with exposure to dust.

2. Compact Design Compared to traditional baghouses, which can take up significant space, filter cartridge dust collectors have a compact design. This makes them ideal for facilities with limited space or those needing to maximize floor space for production.

3. Low Airflow Resistance The design of filter cartridges allows for better airflow, resulting in lower energy costs associated with running the dust collection system. Achieving high airflow with minimal resistance contributes to overall operational efficiency.

4. Easy Maintenance Filter cartridge systems are generally easier to maintain than other dust collection systems. The cartridges can be replaced or cleaned without extensive downtime, minimizing interruption to production processes.

5. Versatility These dust collectors are effective for various applications, from woodworking and metalworking to food processing and pharmaceuticals. Their adaptability to different types of dust makes them an essential tool across different industries.

Considerations for Selecting a Filter Cartridge Dust Collector

When choosing a filter cartridge dust collector, several factors must be considered

filter cartridge dust collector

- Type of Dust Different industries generate varying types of dust, each with unique properties. Knowing the type of dust will help in selecting the appropriate filter material and design.

- Airflow Requirements Understand the volume of air that needs to be filtered to ensure the dust collector can adequately meet operational demands.

- Space Constraints As mentioned, space can be a limiting factor. Assessing the available area can influence the selection between different types and sizes of collectors.

- Maintenance Needs Consider the maintenance requirements and ease of cartridge replacement. Regular maintenance is crucial to ensuring the longevity and effectiveness of the collector.

Maintenance of Filter Cartridge Dust Collectors

To ensure optimal performance, regular maintenance of filter cartridge dust collectors is essential. Here are some tips for keeping these systems running efficiently

1. Regular Inspection Periodically check the cartridges for signs of wear or damage. Early detection of issues can prevent bigger problems down the line.

2. Cleaning Depending on the application, filter cartridges may need to be cleaned or replaced regularly. Automated cleaning systems can enhance the efficiency of dust removal from cartridges.

3. Monitor Pressure Drop Keeping an eye on the pressure drop across the cartridges can give an indication of when maintenance is needed. A significant increase in pressure drop usually indicates that the cartridges are clogged and need attention.

4. Record Keeping Maintain detailed records of inspections, cleaning, and replacements. This documentation can help identify patterns and prevent sudden equipment failures.

Conclusion

Filter cartridge dust collectors are indispensable tools for maintaining clean air in industrial environments. With their high efficiency, compact design, and ease of maintenance, they provide a practical solution for managing airborne dust. By understanding their operation, benefits, and maintenance requirements, businesses can enhance workplace safety and ensure compliance with environmental regulations. Investing in a quality filter cartridge dust collector not only protects employees but also improves overall productivity and product quality.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: