Tel:

+8615930870079

Tel:

+8615930870079

Aug . 01, 2024 01:21 Back to list

Exploring the Benefits and Applications of Vacuum Filter Cartridge Technology in Various Industries

Understanding Vacuum Filter Cartridges A Key Component in Filtration Systems

Filtration is a crucial process in various industries, ensuring that liquids and gases are purified and free from contaminants. One critical component in many filtration systems is the vacuum filter cartridge. Understanding its design, function, and applications can provide insights into its importance in industrial processes.

What is a Vacuum Filter Cartridge?

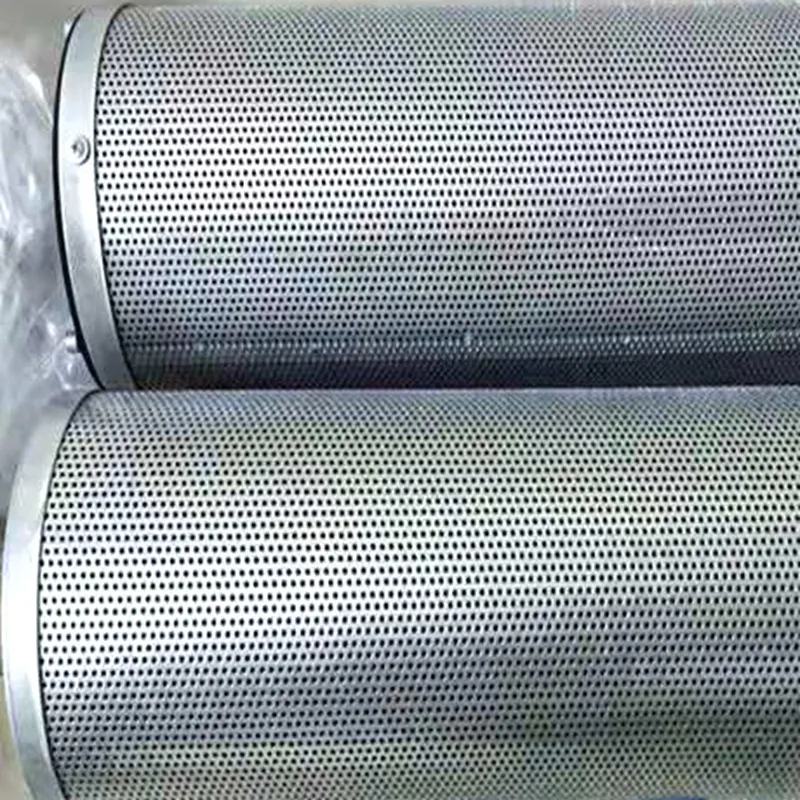

A vacuum filter cartridge is a cylindrical device designed to remove impurities from liquids through the process of filtration. It operates under a vacuum pressure, which enhances the filtration process by reducing the pressure on the liquid passing through the filter media. This design allows for efficient removal of solid particles, bacteria, and other contaminants from the liquid, making it a vital component in numerous applications.

How Does it Work?

The function of a vacuum filter cartridge can be elucidated through its operational mechanism. When a liquid is introduced into the filtration system, a vacuum is created within the cartridge, causing the liquid to flow through the filter media. The filter media, often made from materials such as polypropylene, nylon, or fiberglass, captures solid particles while allowing the clarified liquid to pass through. This process is continuously maintained, enhancing the filter's efficiency and lifespan.

The vacuum created in the cartridge not only expedites the flow of liquid but also reduces the likelihood of channeling, where liquid bypasses the media instead of filtering through it. This ensures a higher quality of filtered liquid and maximizes the efficiency of the filtration process.

Applications of Vacuum Filter Cartridges

vacuum filter cartridge

Vacuum filter cartridges find applications in various sectors, including pharmaceuticals, food and beverage, wastewater treatment, and chemical manufacturing. In the pharmaceutical industry, for instance, these cartridges are crucial in ensuring the purity of solvents, oils, and other essential liquids used in drug formulation processes.

In the food and beverage sector, vacuum filter cartridges are employed to filter juices, oils, and syrups, ensuring that the final products are free from unwanted solids and pathogens. This not only enhances the quality of the products but also extends their shelf life, making it a significant investment for manufacturers.

Moreover, in wastewater treatment plants, vacuum filter cartridges help in the treatment of sewage and industrial effluents. By removing harmful solids and contaminants, these cartridges play a vital role in ensuring that the treated water meets safety and environmental standards before being discharged back into the ecosystem.

Advantages of Vacuum Filter Cartridges

One of the primary benefits of vacuum filter cartridges is their efficiency. The vacuum pressure allows for a faster flow rate compared to gravity-fed systems, leading to higher throughput. Additionally, their compact design requires less space, making them an ideal choice for facilities with limited room for equipment.

Furthermore, the ease of maintenance is another significant advantage. Many vacuum filter cartridges are designed for easy replacement, minimizing downtime during maintenance. The longevity of the filter media also contributes to cost savings, as users can replace cartridges based on performance and condition rather than frequency of use.

Conclusion

In conclusion, vacuum filter cartridges are an indispensable part of modern filtration systems across various industries. Their ability to effectively remove contaminants, coupled with their efficient operation and ease of maintenance, makes them a preferred choice for many applications. As industries continue to prioritize quality and safety, the role of vacuum filter cartridges will undoubtedly remain critical in maintaining the purity of liquids and ensuring compliance with health and environmental regulations. Understanding their function and applications is essential for anyone involved in industrial processes, highlighting the importance of quality filtration in today's world.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: