Tel:

+8615930870079

Tel:

+8615930870079

Aug . 10, 2024 14:05 Back to list

Exploring the Benefits and Applications of Cartridge Filter Vacuum Systems for Efficient Filtration

The Importance of Cartridge Filter Vacuum Systems in Modern Filtration

In the ever-evolving industrial landscape, the need for efficient dust and particulate control has become paramount. One of the prominent technologies paving the way for enhanced filtration is the cartridge filter vacuum system. These systems employ a series of cylindrical elements, or cartridges, to capture airborne particles and pollutants, thereby maintaining a cleaner and healthier work environment.

Understanding Cartridge Filter Vacuum Systems

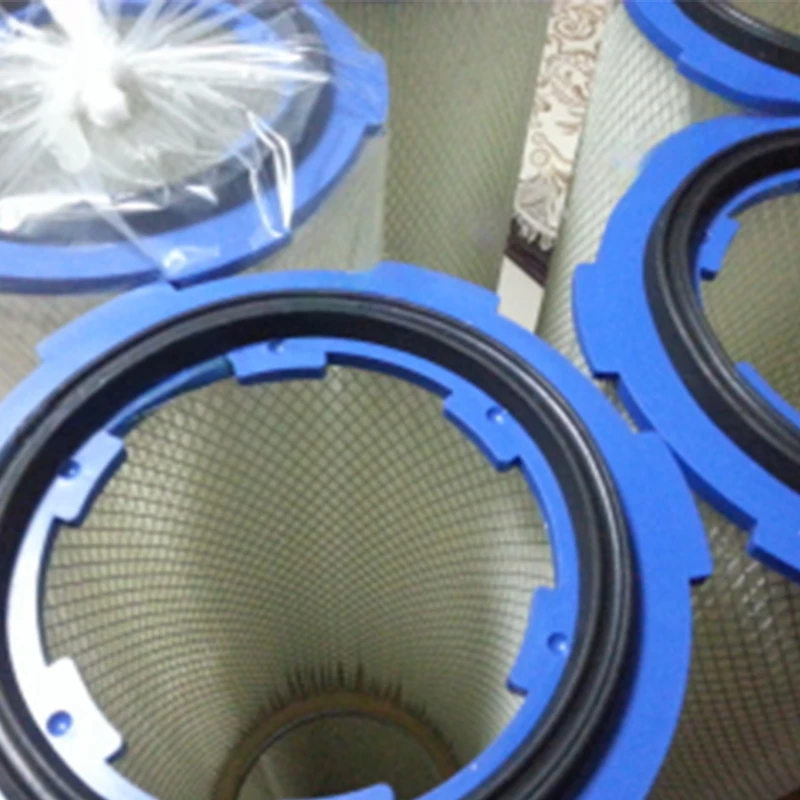

Cartridge filter vacuums are specifically designed to remove fine dust and contaminants from the air. Unlike traditional bag filters, which can suffer from issues related to airflow restriction and maintenance challenges, cartridge filters provide a more reliable solution. Typically composed of durable materials such as polyester or fiberglass, these cartridges feature a larger surface area, allowing for higher filtration efficiency and lower resistance to airflow.

When air laden with dust passes through the cartridge filter, particles are trapped on the surface while clean air is released back into the environment. Over time, these cartridges accumulate dust, necessitating periodic cleaning or replacement. The design of cartridge filter vacuum systems often incorporates automated cleaning mechanisms to dislodge trapped dust, ensuring consistent performance and extended lifespan of the filtration components.

Advantages of Cartridge Filter Vacuum Systems

1. High Efficiency One of the standout features of cartridge filter vacuums is their ability to capture a wide range of particulates, including fine dust and allergens. This is particularly important in industries such as woodworking, pharmaceuticals, and food processing, where air quality standards are stringent.

2. Space-Saving Design Cartridge filters are compact compared to traditional systems, making them ideal for facilities with limited space. Their vertical orientation allows for high filtration capacity without occupying a large footprint.

cartridge filter vacuum

3. Easy Maintenance Many cartridge filter vacuums come with user-friendly designs that make maintenance straightforward. The ability to clean cartridges without demounting them saves time and minimizes downtime.

4. Cost-Effective Operation With higher filtration efficiency and lower energy consumption, cartridge filter systems can significantly reduce operational costs over time. The longer lifespan of cartridges also minimizes replacement frequency, resulting in additional savings.

5. Adaptability These vacuum systems can be integrated into various manufacturing processes. From collecting dust generated in production lines to controlling airborne contaminants in cleanrooms, cartridge filter vacuums are versatile tools that can be tailored to meet specific operational needs.

Applications of Cartridge Filter Vacuums

The versatility of cartridge filter vacuum systems makes them suitable for a wide array of industries. In construction, they help control silica dust; in metalworking, they capture metal shavings and particulate matter; whereas in food processing, they filter out flour and other fine particles, ensuring compliance with health and safety regulations. Many manufacturers also rely on these systems to create a safer workplace by minimizing the risk of respiratory issues associated with airborne dust.

Conclusion

In a world where air quality is increasingly linked to health outcomes, the role of cartridge filter vacuum systems cannot be overemphasized. With their efficient filtration capabilities, ease of maintenance, and adaptability across various applications, they represent a significant advancement in industrial hygiene practices. As industries continue to innovate and adhere to stricter environmental regulations, the adoption of cartridge filter vacuum technology will be critical in promoting a healthier atmosphere for workers and the environment alike. Investing in such systems not only enhances workplace safety but also reflects a commitment to sustainability and responsible manufacturing practices.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: