ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 09, 2025 11:39 Back to list

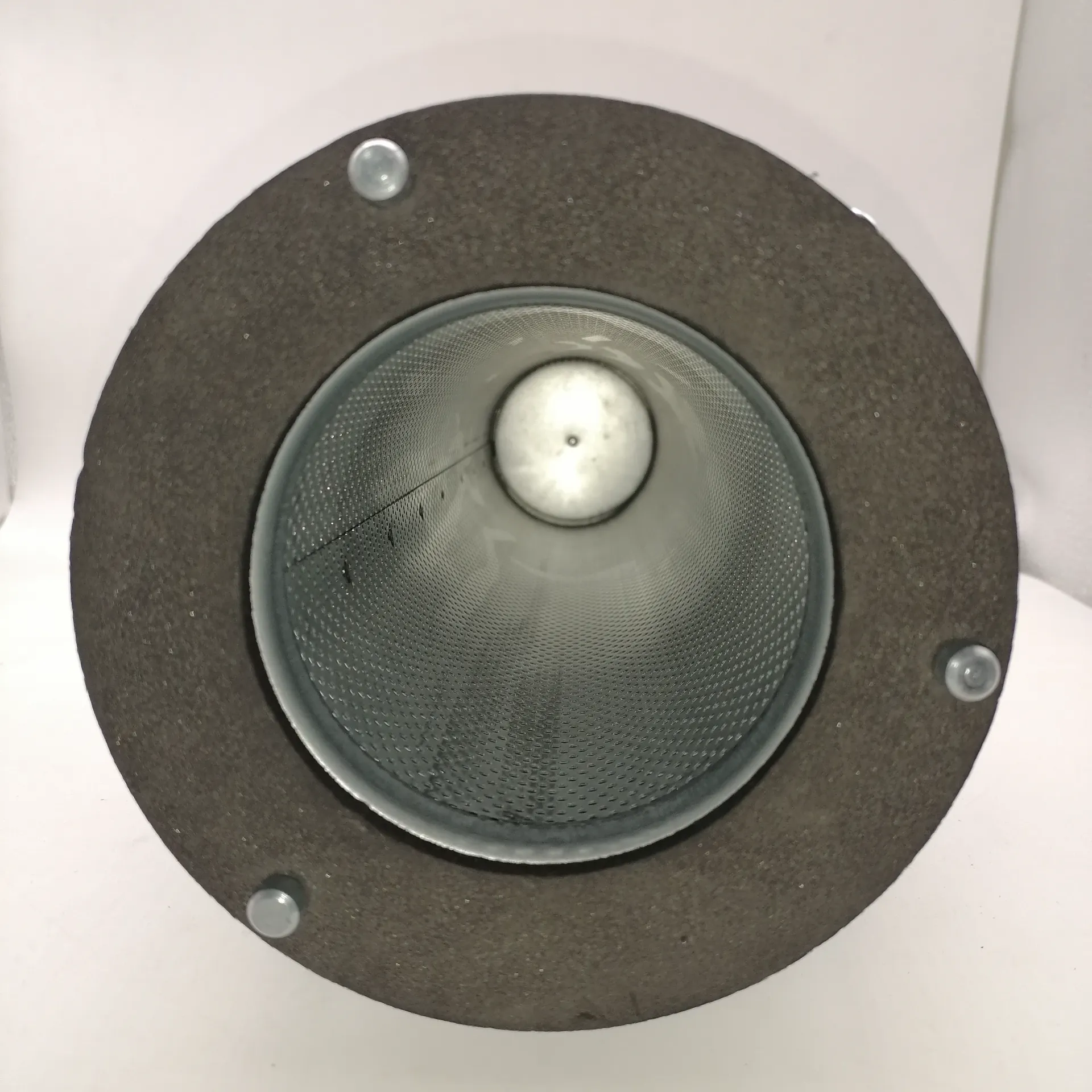

dust extractor cartridge filter

Choosing the right dust extractor filter cartridge is crucial for maintaining a clean and efficient work environment, particularly in industries like woodworking, metalworking, and other dust-intensive settings. Despite the abundance of products available on the market, understanding the nuances of these filter cartridges can elevate your workshop's safety and efficiency.

In terms of expertise, consulting with an industry professional or a dedicated vendor can provide valuable insights into selecting the right filter cartridge. Professionals can offer guidance based on unique application requirements, ensuring the chosen cartridge aligns perfectly with operational goals and machinery specifications. For those concerned about sustainability and cost-effectiveness, it’s important to consider the ease of cleaning and replacing filter cartridges. Many modern filters are designed to be easily cleanable, often with a simple reverse air pulse system, dramatically extending their usable life and reducing replacement costs over time. This factor can be crucial for industries committed to sustainable practices and cost reduction. Lastly, the trustworthiness of the manufacturer should not be overlooked. Opting for cartridges from reputable companies, known for quality assurance and robust customer support, ensures that you receive a product you can rely on. Trusted brands are more likely to carry certifications and comply with industry standards, offering an extra layer of security and peace of mind. In conclusion, selecting the right dust extractor filter cartridge necessitates a blend of expertise, awareness of material properties, and attention to manufacturer reputation. By focusing on these areas, you can significantly enhance the efficiency of your dust collection system, thus securing a cleaner, safer, and more productive environment.

In terms of expertise, consulting with an industry professional or a dedicated vendor can provide valuable insights into selecting the right filter cartridge. Professionals can offer guidance based on unique application requirements, ensuring the chosen cartridge aligns perfectly with operational goals and machinery specifications. For those concerned about sustainability and cost-effectiveness, it’s important to consider the ease of cleaning and replacing filter cartridges. Many modern filters are designed to be easily cleanable, often with a simple reverse air pulse system, dramatically extending their usable life and reducing replacement costs over time. This factor can be crucial for industries committed to sustainable practices and cost reduction. Lastly, the trustworthiness of the manufacturer should not be overlooked. Opting for cartridges from reputable companies, known for quality assurance and robust customer support, ensures that you receive a product you can rely on. Trusted brands are more likely to carry certifications and comply with industry standards, offering an extra layer of security and peace of mind. In conclusion, selecting the right dust extractor filter cartridge necessitates a blend of expertise, awareness of material properties, and attention to manufacturer reputation. By focusing on these areas, you can significantly enhance the efficiency of your dust collection system, thus securing a cleaner, safer, and more productive environment.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: