ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 26, 2025 05:25 Back to list

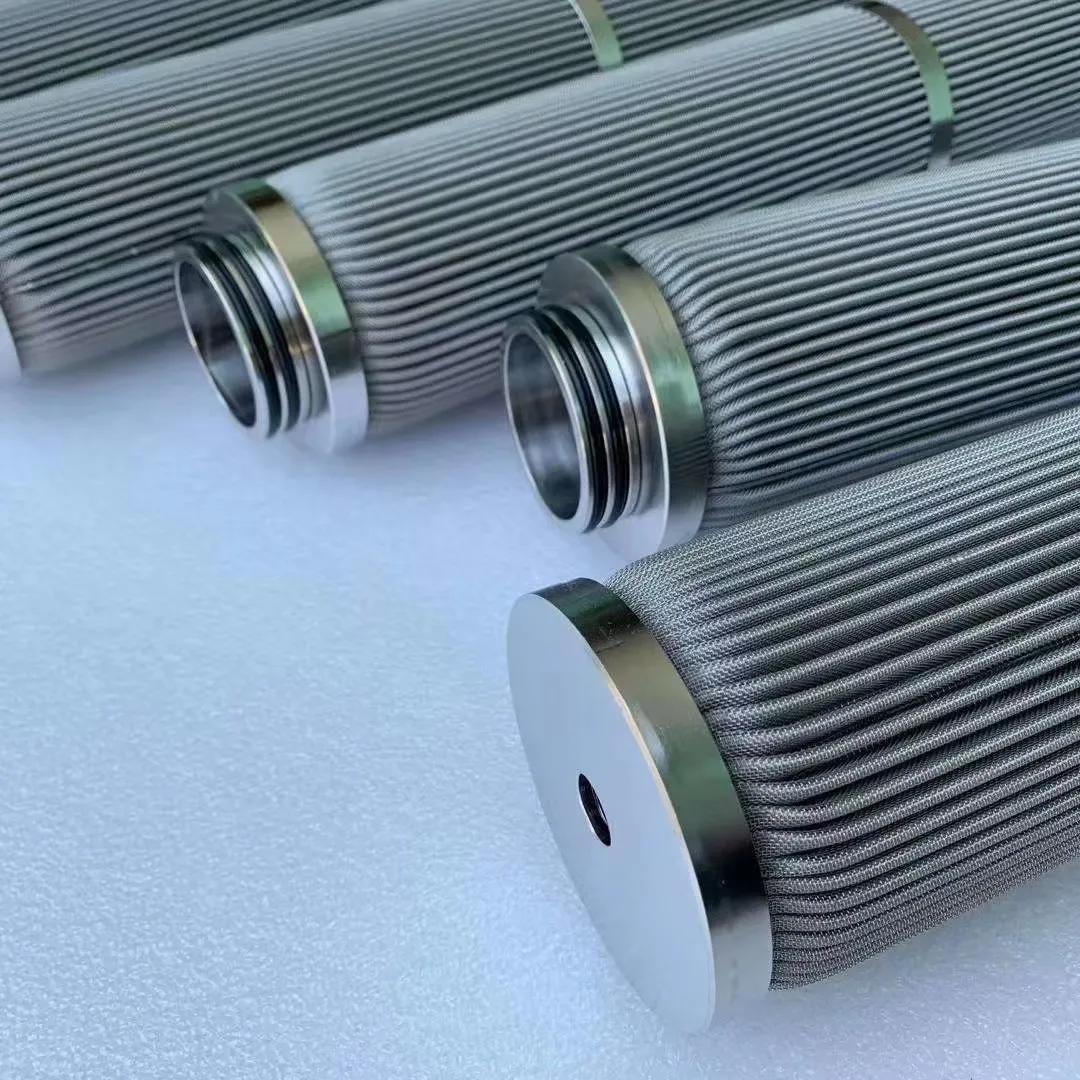

pleated filter cartridge dust collector

For industries dependent on efficient filtration systems, the introduction and enhancement of the dust collector pleated filter is nothing short of revolutionary. This technological leap has redefined the way we perceive and handle air quality, bringing about unparalleled advancements in both operational efficiency and environmental responsibility.

Furthermore, the versatility of pleated filters extends to their adaptability across various sectors. Whether it be automotive, pharmaceuticals, food processing, or heavy manufacturing, these filters can be tailored to meet the specific requirements of each industry. This versatility highlights the design’s authoritative engineering, offering ease of installation and operation without requiring substantial modifications to existing systems. Trust in these filtration systems is cemented by their performance over time. Industries report significant reductions in maintenance time and costs, as pleated filters do not demand frequent replacements and deliver consistent results throughout their lifecycle. Moreover, manufacturers offer comprehensive support and warranties, attesting to the enduring reliability of their products and providing an added layer of assurance to businesses. To cap it all, the shift towards pleated filters symbolizes a broader commitment to innovation and excellence in filtration technology. They represent a blend of efficiency, reliability, and sustainability, offering a future-proof solution that benefits not just industries but society as a whole. As businesses continue to face stringent environmental regulations and pressure to optimize operational costs, these filters provide a pathway to meet and exceed expectations. In conclusion, the evolution of the dust collector pleated filter marks a significant milestone in filtration technology, demonstrating clear advantages in air quality improvement, cost efficiency, and environmental sustainability. Its adoption is a testament to its proven ease of use and effectiveness, epitomizing a trusted solution in the ever-evolving landscape of industrial filtration. As industries prioritize health, efficiency, and eco-conscious practices, the role of pleated filters is expected to expand, undeniably marking them as a cornerstone of modern industrial filtration systems.

Furthermore, the versatility of pleated filters extends to their adaptability across various sectors. Whether it be automotive, pharmaceuticals, food processing, or heavy manufacturing, these filters can be tailored to meet the specific requirements of each industry. This versatility highlights the design’s authoritative engineering, offering ease of installation and operation without requiring substantial modifications to existing systems. Trust in these filtration systems is cemented by their performance over time. Industries report significant reductions in maintenance time and costs, as pleated filters do not demand frequent replacements and deliver consistent results throughout their lifecycle. Moreover, manufacturers offer comprehensive support and warranties, attesting to the enduring reliability of their products and providing an added layer of assurance to businesses. To cap it all, the shift towards pleated filters symbolizes a broader commitment to innovation and excellence in filtration technology. They represent a blend of efficiency, reliability, and sustainability, offering a future-proof solution that benefits not just industries but society as a whole. As businesses continue to face stringent environmental regulations and pressure to optimize operational costs, these filters provide a pathway to meet and exceed expectations. In conclusion, the evolution of the dust collector pleated filter marks a significant milestone in filtration technology, demonstrating clear advantages in air quality improvement, cost efficiency, and environmental sustainability. Its adoption is a testament to its proven ease of use and effectiveness, epitomizing a trusted solution in the ever-evolving landscape of industrial filtration. As industries prioritize health, efficiency, and eco-conscious practices, the role of pleated filters is expected to expand, undeniably marking them as a cornerstone of modern industrial filtration systems.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: