Tel:

+8618931101301

Tel:

+8618931101301

Jul . 18, 2025 15:51 Back to list

Installation and use of air filter, product features, maintenance, and manufacturing process

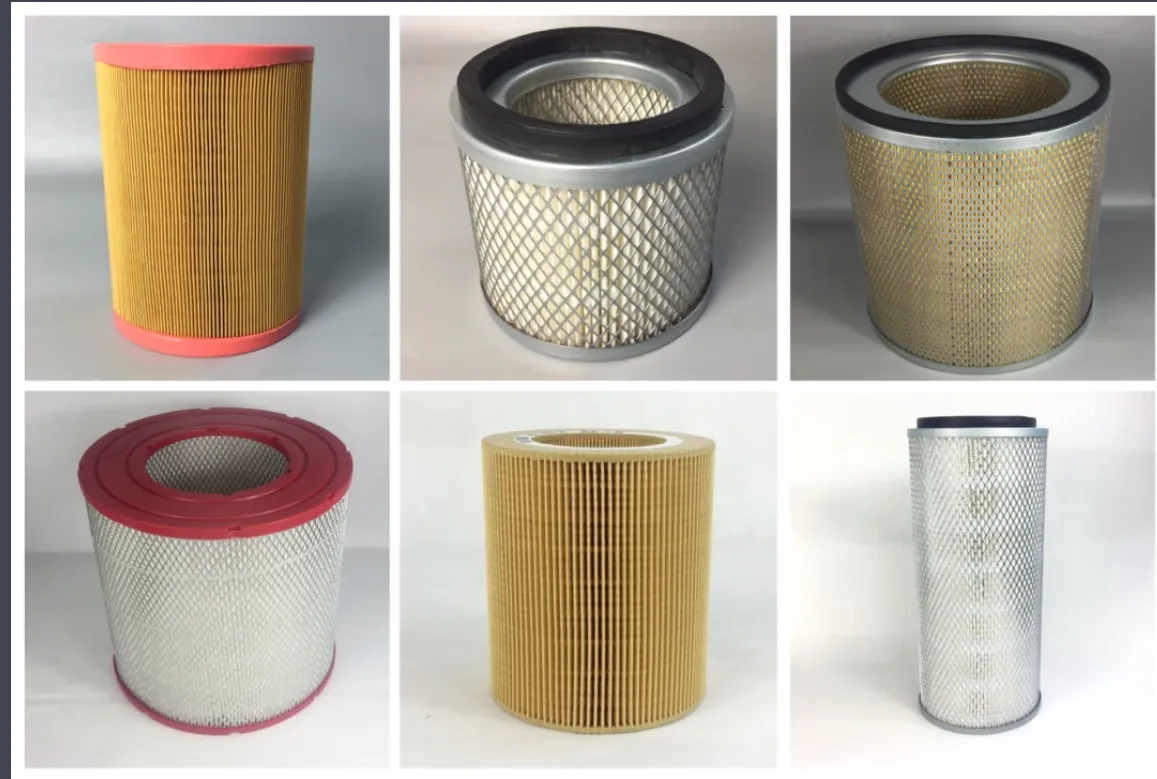

Air filter type:

According to the filtering principle, air filters can be divided into filter type, centrifugal type, oil bath type, and composite type. The commonly used air filters in engines mainly include inertial oil bath air filters, paper dry air filters, polyurethane filter air filters, etc.

The inertial oil bath air filter undergoes three levels of filtration, namely inertial filtration, oil bath filtration and filter filtration. The latter two types of air filters are mainly filtered by element filtration. The inertial oil bath air filter has the advantages of small intake resistance, adaptability to dusty and sandy working environment, and long service life. It was previously used on various models of automobile and tractor engines. However, this type of air filter has low filtration efficiency, heavy weight, high cost, and inconvenient maintenance, and has been gradually eliminated in automobile engines.

The filter element of the paper dry air filter is made of microporous filter paper treated with resin. The filter paper is porous, loose, folded, has certain mechanical strength and water resistance, has the advantages of high filtration efficiency, simple structure, light weight, low cost, and convenient maintenance. It is the most widely used automotive air filter.

The filter element of the polyurethane filter air filter is made of soft, porous, sponge-like polyurethane with strong adsorption capacity. This air filter has the advantages of paper dry air filter, but has low mechanical strength and is widely used in car engines.

The disadvantages of the latter two air filters are short service life and unreliable operation under harsh environmental conditions.

New air filters

Various air filters have their own advantages and disadvantages, but inevitably there is a contradiction between the air intake volume and the filtration efficiency. With the in-depth research on air filters, the requirements for air filters are getting higher and higher. Some new air filters have emerged, such as fiber filter element air filters, compound filter material air filters, silencer air filters, constant temperature air filters, etc., to meet the needs of engine operation.

Installation and Use

- During installation, whether the air filter and the engine intake pipe are connected by flange, rubber tube or direct connection, they must be tight and reliable to prevent air leakage. Rubber gaskets must be installed on both ends of the filter element; the wing nuts that fix the air filter cover should not be tightened too much to avoid crushing the paper filter element.

2. During maintenance, the paper filter element must not be cleaned in oil, otherwise the paper filter element will fail and it is easy to cause a runaway accident. During maintenance, only vibration method, soft brush removal method (brush along its wrinkles) or compressed air backblowing method can be used to remove dust and dirt attached to the surface of the paper filter element. For the coarse filter part, dust should be removed from the dust collecting part, blades and cyclone tubes in time. Even if it is carefully maintained every time, the paper filter element cannot completely restore its original performance, and its intake resistance will increase. Therefore, generally when the paper filter element needs to be maintained for the fourth time, a new filter element should be replaced. If the paper filter element is cracked, perforated, or the filter paper and the end cover are debonded, it should be replaced immediately.

3. When using, be sure to prevent the paper core air filter from getting wet by rain, because once the paper core absorbs a lot of water, it will greatly increase the intake resistance and shorten the mission. In addition, the paper core air filter cannot come into contact with oil and fire.

4. Some vehicle engines are equipped with cyclone air filters. The plastic cover at the end of the paper filter is a guide cover. The blades on the cover make the air rotate. 80% of the dust is separated by centrifugal force and collected in the dust cup. The dust that reaches the paper filter is 20% of the inhaled dust. The total filtration efficiency is about 99.7%. Therefore, when maintaining the cyclone air filter, be careful not to miss the plastic guide cover on the filter element.

Maintenance

- 1、The filter element is the core component of the filter. It is made of special materials and is a consumable part. It requires special maintenance and care;

2. After the filter has been working for a long time, the filter element has intercepted certain impurities, which will cause the pressure to increase and the flow to decrease. At this time, it needs to be cleaned in time;

3. When cleaning, be sure not to deform or damage the filter element.

Generally, the service life of the filter element varies according to the different raw materials used. However, as the use time increases, impurities in the air will clog the filter element. Therefore, generally speaking, the PP filter element needs to be replaced every three months; the activated carbon filter element needs to be replaced every six months; and the fiber filter element cannot be cleaned, so it is generally placed at the back end of the PP cotton and activated carbon, which is not easy to cause clogging; the ceramic filter element can usually be used for 9-12 months.

- The filter paper in the equipment is also one of the key factors. The filter paper in high-quality filtering equipment usually uses ultra-fine fiber paper filled with synthetic resin, which can effectively filter impurities and has a strong ability to store pollutants. According to relevant statistics, a bus with an output power of 180 kilowatts will filter out about 1.5 kilograms of impurities in 30,000 kilometers of driving. In addition, the equipment also has great requirements for the strength of the filter paper. Due to the large air flow, the strength of the filter paper can withstand strong airflow, ensure the efficiency of filtration, and extend the service life of the equipment.

-

Product Features

It is becoming more and more common to use paper core air filters in modern automobile engines, but some drivers still have prejudices against paper core air filters, believing that the filtering effect of paper core air filters is not good. In fact, compared with oil bath air filters, paper core air filters have more advantages: first, the filtration efficiency is as high as 99.5% (oil bath air filters are 98%), and the dust penetration rate is only 0.1%-0.3%; second, the structure is compact and can be installed in any direction without being restricted by the layout of vehicle parts; third, it does not consume oil during maintenance, and can also save a lot of cotton yarn, felt and metal materials; fourth, it is small in weight and low in cost. Therefore, drivers can use it with confidence.

The key to using paper core air filters well is to maintain their sealing performance and prevent unfiltered air from bypassing and entering the engine cylinder.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: