Tel:

+8615930870079

Tel:

+8615930870079

Jul . 23, 2024 14:38 Back to list

Choosing the Right Filter Cartridge for Your Dust Collector System Efficiency and Performance

Filter Cartridge Dust Collector A Comprehensive Overview

In various industries, the management of airborne dust and particulate matter is crucial for maintaining a safe and productive work environment. One of the most efficient solutions for this purpose is the filter cartridge dust collector. This equipment plays a pivotal role in capturing and filtering out dust particles, ensuring compliance with environmental regulations, and promoting a healthier workplace.

What is a Filter Cartridge Dust Collector?

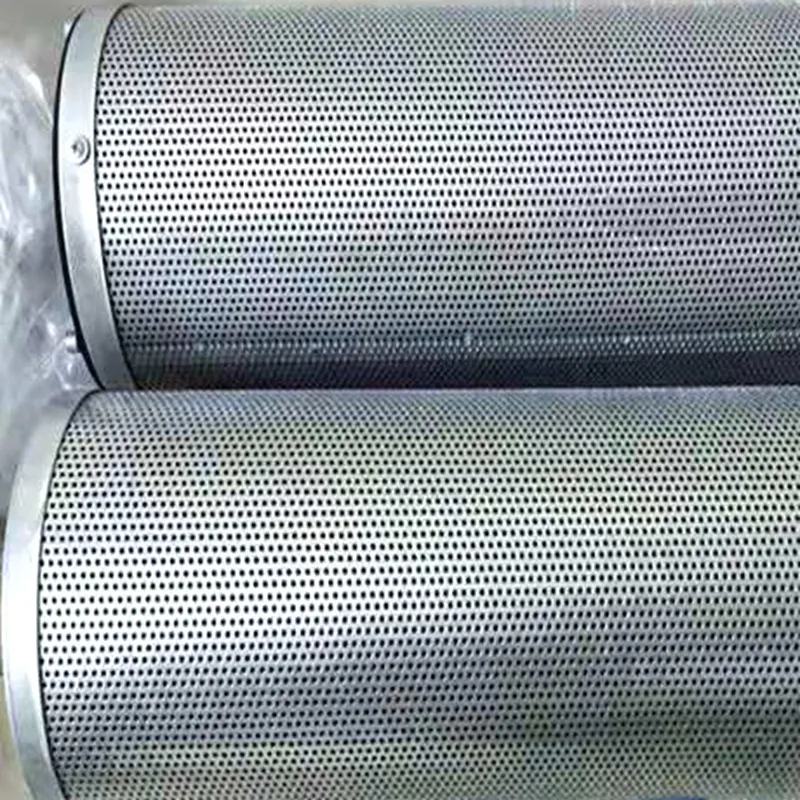

A filter cartridge dust collector is an air pollution control device that utilizes a series of filter cartridges to remove dust particles from industrial air streams. These collectors are designed to handle a wide range of dust types, including those generated in manufacturing, woodworking, metalworking, and food processing industries. The system operates by forcing contaminated air through the filter cartridges, where particles are trapped, and clean air is then released into the atmosphere.

How Does It Work?

The operation of a filter cartridge dust collector typically involves several key components. The system begins with a fan that draws in dusty air from the work environment. This air is then directed through the filter cartridges, which are made from various materials depending on the specific application and type of dust being collected.

As the air passes through the cartridges, larger particles are captured on the surface, while smaller particles are trapped in the internal fibers of the cartridge media. Over time, as more dust accumulates, the airflow resistance increases, necessitating a cleaning process. Most modern systems employ automated cleaning mechanisms, such as pulse jet or shaker systems, to dislodge and remove accumulated dust from the cartridges, ensuring continuous operation and optimal performance.

Advantages of Filter Cartridge Dust Collectors

1. Efficient Dust Removal Filter cartridge dust collectors are capable of capturing a high percentage of airborne dust particles, often achieving efficiencies of 99% or greater. This makes them ideal for industries with stringent air quality standards.

filter cartridge dust collector

2. Compact Design Compared to traditional baghouse collectors, filter cartridge systems generally occupy less floor space, making them suitable for facilities with limited space.

3. Ease of Maintenance The design of filter cartridge dust collectors allows for quick and easy cartridge replacement and cleaning, minimizing downtime and maintenance costs.

4. Versatility These collectors can handle a wide variety of dust types, from fine powders to heavier particles, making them incredibly versatile in their applications.

5. Reduced Emissions By capturing dust before it can escape into the atmosphere, these systems help companies comply with environmental regulations and reduce their carbon footprint.

Applications

Filter cartridge dust collectors are widely used across various industries. In woodworking, they help manage sawdust and wood shavings; in metalworking, they capture metal filings and dust; while in food processing, they effectively deal with flour and sugar dust. These collectors are also utilized in the pharmaceutical industry to reduce contamination risks and improve air quality in production facilities.

Conclusion

In conclusion, the filter cartridge dust collector represents a critical component of modern industrial operations. By effectively managing airborne dust, these systems not only enhance workplace safety and employee health but also ensure compliance with environmental regulations. As industries continue to place a strong emphasis on sustainability and air quality, the importance of efficient dust collection solutions like filter cartridge systems will only continue to grow. Investing in such technology is not merely a regulatory requirement; it is a step towards a greener and healthier future for all.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: