Tel:

+8615930870079

Tel:

+8615930870079

Jul . 28, 2024 09:16 Back to list

Choosing the Right Antistatic Filter Element for Optimal Performance and Protection in Various Applications

Understanding Antistatic Filter Elements Importance, Functionality, and Applications

In today’s industrial landscape, maintaining cleanliness and preventing contamination in manufacturing processes is of paramount importance. One innovation that has greatly enhanced the integrity of various production environments is the antistatic filter element. These specialized components are designed to mitigate the risks associated with static electricity, which can lead to the accumulation of dust and other particulate matter in sensitive processes.

What is an Antistatic Filter Element?

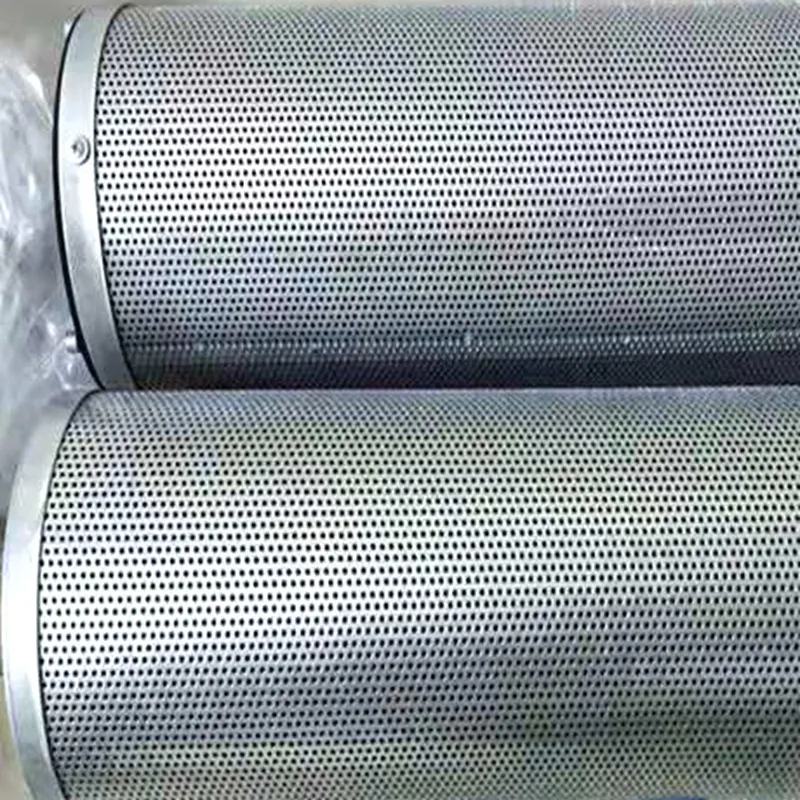

An antistatic filter element is a filtration medium that incorporates special features to resist static buildup, ensuring that airborne contaminants are captured effectively while maintaining optimal airflow. These elements are typically made from a blend of synthetic fibers that have been treated to dissipate static electricity. By minimizing static charge accumulation, these filters effectively reduce the attraction of dust particles, maintaining a cleaner environment and prolonging the life of equipment.

Why is Antistatic Technology Important?

Static electricity can have detrimental effects in many industrial settings. It can cause equipment malfunctions, interfere with electronic components, and even pose a fire hazard in environments with flammable materials. In industries such as pharmaceuticals, electronics, and food production, the presence of static can lead to product contamination, thus compromising quality and safety. Antistatic filter elements play a critical role in preventing these risks, ensuring that production environments remain stable and secure.

Functionality of Antistatic Filter Elements

Antistatic filter elements function through both mechanical and electrostatic filtration mechanisms. The mechanical aspect involves the physical trapping of particles as air passes through the filter material. The electrostatic component works by preventing the buildup of static charges that could attract additional particles. This dual-action approach provides a comprehensive solution for maintaining air quality, particularly in cleanroom environments where precision is essential.

When installed in HVAC systems or as part of individual machinery, antistatic filter elements can significantly improve the overall efficiency of air filtration systems

. By ensuring that static charge does not increase during operation, these filters help to minimize wear and tear on equipment, thereby reducing maintenance costs and downtime.antistatic filter element

Applications of Antistatic Filter Elements

The applications of antistatic filter elements span across multiple industries, including

1. Electronics Manufacturing In this industry, the delicate components are highly sensitive to static electricity. Antistatic filters help in creating a static-free environment, which is essential for preventing defects during assembly and ensuring product reliability.

2. Pharmaceuticals Cleanliness and sterility are critical in pharmaceutical production. Antistatic filters aid in maintaining a contamination-free atmosphere, protecting both the products and the health of consumers.

3. Food Processing In food manufacturing, static can attract dust and other contaminants, compromising food safety. Antistatic filter elements enhance air quality, supporting compliance with health standards.

4. Automotive In the automotive sector, static charge can affect the painting and assembly processes. Utilizing antistatic filters ensures a clean operation, leading to better finishes and reduced defects.

Conclusion

In conclusion, antistatic filter elements are essential components in creating and maintaining clean, safe industrial environments. Their ability to prevent static electricity buildup and capture airborne contaminants is crucial in numerous applications, ranging from electronics to pharmaceuticals. As industries continue to prioritize cleanliness and efficiency, antistatic filter elements will remain a vital part of the filtration landscape, contributing to improved operational performance and product integrity.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: