ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

Jan . 14, 2025 12:33 Back to list

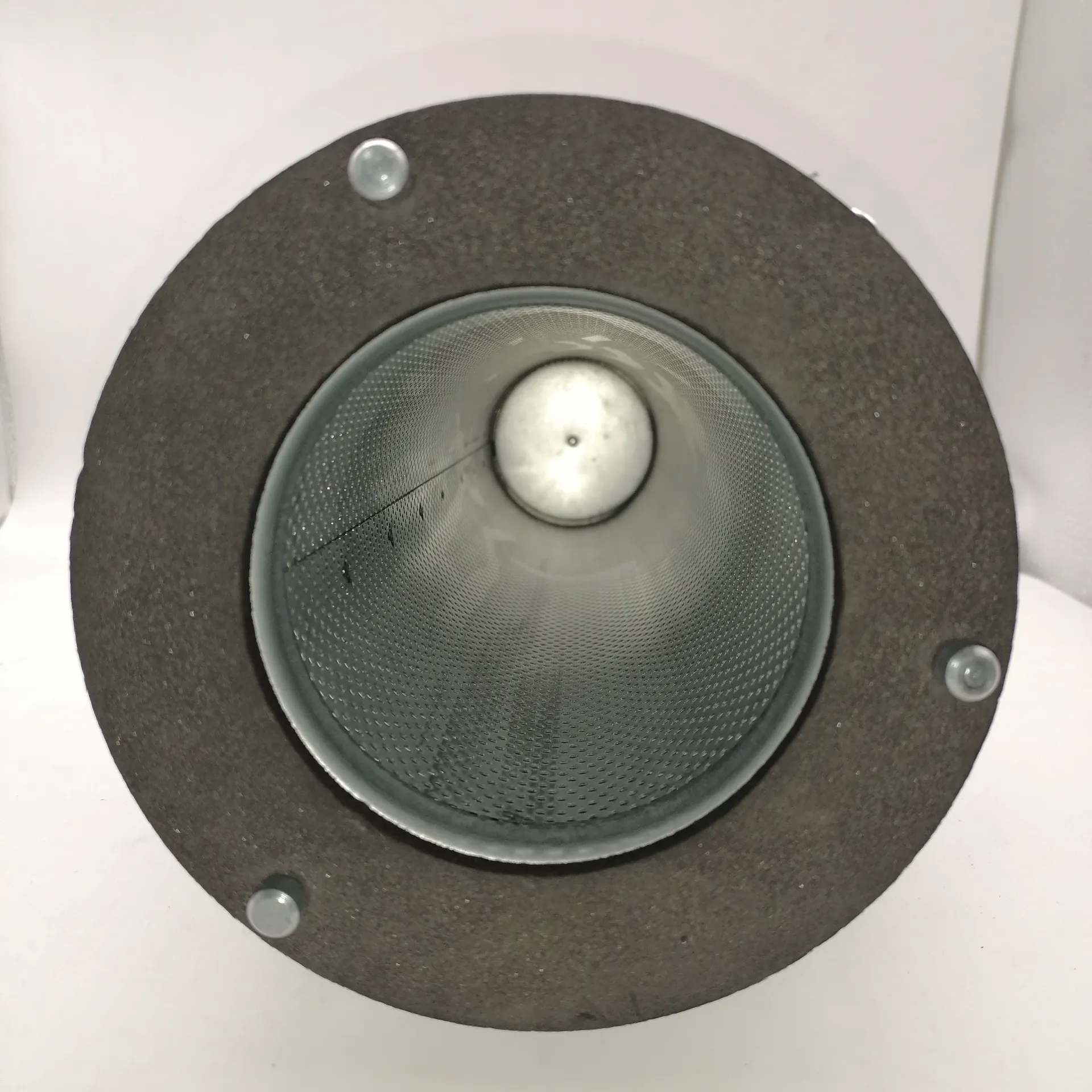

cartridge vacuum filter

Navigating the world of industrial filtration systems often leads to discussions about the efficient and versatile cartridge vacuum filter. As a staple in various industries—ranging from manufacturing to automotive—this filtration system provides a remarkable solution for maintaining clean and functional workspaces, ensuring both equipment longevity and operational efficiency.

Authoritativeness in the field often reflects in the manufacturers and suppliers who produce top-tier cartridge vacuum filters. Leading brands typically engage in rigorous testing and quality assurance processes, ensuring their products meet the stringent standards applicable in sectors such as pharmaceuticals, food processing, and heavy machinery. Adhering to these certifications not only asserts the manufacturer’s commitment to quality but also instills confidence among users relying on these systems for critical operations. Trust plays a critical role in the selection and use of cartridge vacuum filters. Choosing dependable equipment backed by excellent service guarantees reduces the anxiety of operational failures. Industry leaders provide comprehensive warranties and support services, ensuring customers can rely on their products to maintain operational continuity. For businesses invested in achieving sustainable operations, cartridge vacuum filters also address environmental concerns by providing eco-friendly filtration options. Many modern designs incorporate washable and reusable cartridges, drastically cutting down waste associated with disposable alternatives. Such innovations not only comply with environmental regulations but also enhance the company’s green credentials. In conclusion, the unique blend of experience, expertise, authoritativeness, and trustworthiness informs the implementation of cartridge vacuum filters across industries. By choosing the right filter and investing in quality options from reputable manufacturers, companies can enjoy cleaner environments, enhanced productivity, and reduced maintenance costs—benefits that undeniably make these systems an essential component of modern industrial operations.

Authoritativeness in the field often reflects in the manufacturers and suppliers who produce top-tier cartridge vacuum filters. Leading brands typically engage in rigorous testing and quality assurance processes, ensuring their products meet the stringent standards applicable in sectors such as pharmaceuticals, food processing, and heavy machinery. Adhering to these certifications not only asserts the manufacturer’s commitment to quality but also instills confidence among users relying on these systems for critical operations. Trust plays a critical role in the selection and use of cartridge vacuum filters. Choosing dependable equipment backed by excellent service guarantees reduces the anxiety of operational failures. Industry leaders provide comprehensive warranties and support services, ensuring customers can rely on their products to maintain operational continuity. For businesses invested in achieving sustainable operations, cartridge vacuum filters also address environmental concerns by providing eco-friendly filtration options. Many modern designs incorporate washable and reusable cartridges, drastically cutting down waste associated with disposable alternatives. Such innovations not only comply with environmental regulations but also enhance the company’s green credentials. In conclusion, the unique blend of experience, expertise, authoritativeness, and trustworthiness informs the implementation of cartridge vacuum filters across industries. By choosing the right filter and investing in quality options from reputable manufacturers, companies can enjoy cleaner environments, enhanced productivity, and reduced maintenance costs—benefits that undeniably make these systems an essential component of modern industrial operations.

Next:

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: