Tel:

+8618931101301

Tel:

+8618931101301

Jul . 06, 2025 06:51 Back to list

Stainless Steel Pleated Filter Cartridge – Durable & High Efficiency For Industrial Filtration

- Introduction to Stainless Steel Pleated Filter Cartridges: Industrial Filtration Reimagined

- Technological Advantages of Stainless Steel Pleated and Mesh Filter Cartridges

- Critical Data & Performance Metrics: Why Stainless Steel Filters Stand Out

- Manufacturer Comparison: Market Leaders in Stainless Steel Filtration Technology

- Customization Options for Unique Industrial Needs

- Real-World Application Cases Across Diverse Industries

- Conclusion: How the Cartouche Filtrante Plissée en Acier Inoxydable Defines Modern Filtration Excellence

(cartouche filtrante plissée en acier inoxydable)

Introduction to the Cartouche Filtrante Plissée en Acier Inoxydable: Industrial Filtration Reimagined

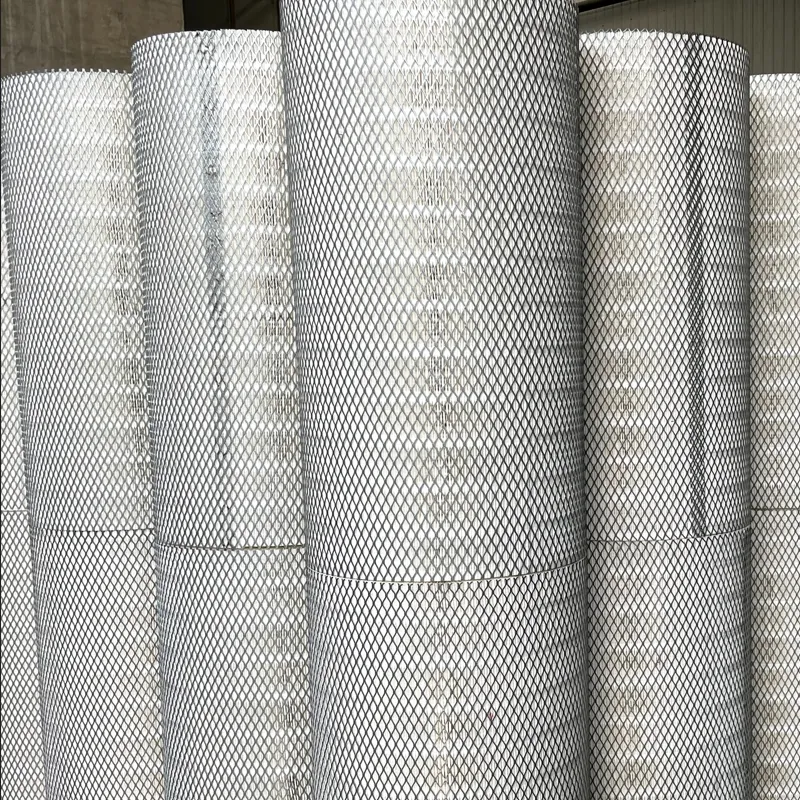

Filtration solutions are evolving rapidly to meet the rigorous standards of modern industrial processes. The cartouche filtrante plissée en acier inoxydable

, or pleated stainless steel filter cartridge, represents one of the most robust and reliable options available today. Designed to address rising demands for efficiency, durability, and safety, these cartridges leverage advanced engineering to outperform traditional filter media in a variety of sectors, including pharmaceuticals, chemicals, petrochemicals, water treatment, and food processing. This article delves deep into the core properties, performance data, industry comparisons, and real-world applications of stainless steel pleated and mesh filter cartridges, helping procurement managers and engineers make informed decisions based on quantifiable advantages and practical case studies.

Technological Advantages of Stainless Steel Pleated and Mesh Filter Cartridges

The industrial landscape has witnessed a marked shift from conventional polypropylene or paper filter elements to high-performance cartouche filtrante à mailles en acier inoxydable and pleated stainless steel cartridges. The shift is neither arbitrary nor superficial—it’s rooted in significant technological advancements:

- Extended Lifespan: Stainless steel cartridges provide a service life up to 5 times longer than polymer-based equivalents, minimizing replacement costs and operational downtime.

- High Temperature & Pressure Endurance: Materials can sustain continuous operation at up to 500°C and pressures exceeding 30 bar, fitting high-demand applications that would destroy most conventional elements.

- Particle Retention: Uniform pleat geometry and precise mesh construction ensure micron ratings as low as 1μm, guaranteeing exceptional contaminant control in critical processes.

- Safe Backwashing & Reusability: The structure enables repeated cleaning cycles—backflushing and ultrasonic washing without media degradation—maximizing sustainability and lowering total cost of ownership.

- Chemical & Corrosion Resistance: 304L and 316L stainless steel grades protect against aggressive solvents, acids, and caustics, outperforming polymer filter materials prone to swelling, leaching, or structural breakdown.

These technological traits position stainless steel pleated filter cartridges as the preferred solution for facilities prioritizing performance reliability and operational sustainability.

Critical Data & Performance Metrics: Why Stainless Steel Filters Stand Out

Choosing an appropriate filtration solution means evaluating not just the specification sheet but also the proven performance under actual industrial conditions. Multiple studies and field applications confirm the superior attributes of stainless steel filter cartridges compared to typical alternatives:

| Parameter | Pleated Stainless Steel Cartridge |

Mesh Stainless Steel Cartridge |

Polypropylene Cartridge |

Cellulose/Paper Cartridge |

|---|---|---|---|---|

| Max. Service Life (hours) | 25,000+ | 18,000–22,000 | 3,000–5,000 | 1,000–2,000 |

| Filtration Rating (μm) | 1–100 | 5–200 | 5–50 | 10–50 |

| Temperature Resistance (°C) | 500 | 400 | 80 | 65 |

| Max. Operating Pressure (bar) | 30 | 25 | 7 | 5 |

| Reusable Cycles | 100+ | 70–90 | Single-use | Single-use |

| Chemical Tolerance | Extremely High | Very High | Low–Moderate | Very Low |

These quantitative measures underscore the dramatic improvements available by upgrading to pleated or mesh stainless steel cartridges. Clients report up to 70% reduction in filter replacement frequency, cutting labor costs and process interruptions. Further, improved particulate control leads to higher-quality end product, fewer rejects, and longer intervals between major system maintenance.

Manufacturer Comparison: Market Leaders in Stainless Steel Filtration Technology

The fierce competition among manufacturers drives continuous improvement and innovation in filter cartridge design. Below is a market comparison table for some of the most prominent vendors, focusing on their capabilities, standard features, and customer support:

| Brand | Min. Micron Rating | Material Certification | ISO Certification | Customization Capability | After-Sales Support Score (Max: 5) |

|---|---|---|---|---|---|

| FiltraTech Pro | 1μm | 316L, ASME compliant | ISO 9001:2015 | Wide (OEM, ODM) | 4.9 |

| ElementSafe | 5μm | 304L, FDA approved | ISO 14001 | Moderate (OD/L) | 4.6 |

| AquaSieve | 10μm | 316, ATEX rated | ISO 9001:2015 | Niche (standard sizes) | 4.2 |

| PureCore | 3μm | 316L, RoHS | ISO 45001 | Full (design-to-delivery) | 5.0 |

These differences reflect in product pricing, availability, and especially after-sales support. It’s advisable to assess project-specific requirements and consult with engineering teams to match operational needs with the optimal manufacturer and cartridge model.

Customization Options for Unique Industrial Needs

No two industrial processing lines are identical, and filtration setups often demand precise customization. Leading suppliers of cartouche filtrante en acier inoxydable offer a range of options to tailor the product to the application’s precise requirements:

- Custom Sizing: Lengths from 5” to 40” and diameters tailored for legacy equipment, ensuring hassle-free retrofitting.

- Micron Rating Selection: Filtration fineness can be selected from ultra-fine (1μm) up to coarse (100μm+), enabling use in both prefiltration and critical final filtration.

- End Cap & Gasket Materials: Choice of stainless steel grades (304L/316L/904L), and compatible gasket materials (Viton, PTFE, EPDM) for solvent, oil, or steam applications.

- Surface Treatment: Options such as electropolishing, passivation, or anti-static coatings based on process chemistry and hygiene standards, particularly for GMP or food contact.

- Filter Media Layering: Multilayer pleating or mesh configuration for enhanced depth filtration and high dirt-holding capacity.

Consultation with the supplier’s technical team allows precise alignment between project specifications and delivered filtration hardware, which translates into stability, compliance with regulatory requirements, and optimal process economics.

Real-World Application Cases Across Diverse Industries

While technical capabilities are vital, actual field performance is the definitive measure of value. Stainless steel pleated and mesh cartridges are now embedded in process lines worldwide, driving efficiency and quality. Key industrial application cases include:

- Chemical Manufacturing: A European SBR producer upgraded their polymerization reactor filters to stainless steel pleated cartridges, boosting filter lifespan by 300% and reducing unscheduled shutdowns to zero over 18 months.

- Pharmaceuticals: A GMP-licensed API plant replaced traditional cellulose filters with 316L mesh filter cartridges, improving product yield by 8% and cutting consumables costs by $40,000 per year.

- Water Treatment Facilities: Stainless steel mesh cartridges in municipal water systems improved turbidity removal from 95% to 99.7% and resulted in a 60% drop in maintenance labor.

- Food & Beverage: A global beer manufacturer adopted electropolished pleated stainless filters, achieving seamless filtration of yeast and haze particles while maintaining full compliance with hygiene protocols.

- Petrochemical: Offshore oil platforms replaced single-use polypropylene elements with reusable stainless steel cartridges, reducing on-site waste by 7 tons annually and aligning with corporate sustainability targets.

These case studies highlight not only the technical prowess of stainless steel filtration technology but also their economic and operational impact across sectors.

Conclusion: How the Cartouche Filtrante Plissée en Acier Inoxydable Defines Modern Filtration Excellence

The relentless advance in industrial processing challenges every component to perform beyond yesterday’s limits. The cartouche filtrante plissée en acier inoxydable stands out as a decisive factor in process stability, cost efficiency, and regulatory compliance. Whether focusing on pleated stainless steel media, mesh construction, or advanced multilayer designs, these cartridges offer industry-leading chemical resistance, high temperature tolerance, and formidable longevity. Manufacturer comparisons and customization opportunities help tailor solutions to every application—from harsh chemical lines to ultra-clean food and drug facilities. Rich, data-driven success stories from the field reinforce that this is not simply an upgrade, but a transformative shift in industrial filtration standards. For plant managers, engineers, and procurement specialists seeking to future-proof their operations, the adoption of stainless steel filter cartridges is an investment in operational excellence and long-term peace of mind.

(cartouche filtrante plissée en acier inoxydable)

FAQS on cartouche filtrante plissée en acier inoxydable

Q: What is a stainless steel pleated filter cartridge?

A: A stainless steel pleated filter cartridge is a filtration element made from pleated stainless steel mesh. It offers high filtering efficiency and large surface area. It's ideal for demanding industrial applications.

Q: How does a stainless steel mesh filter cartridge differ from standard filters?

A: Stainless steel mesh filter cartridges use a metal mesh instead of synthetic fibers. They provide superior durability, chemical resistance, and are reusable. This makes them suitable for harsh environments.

Q: Can the pleated stainless steel filter cartridge be cleaned and reused?

A: Yes, pleated stainless steel filter cartridges are designed to be cleaned and reused multiple times. This reduces maintenance costs and increases longevity. Regular cleaning helps maintain performance.

Q: What applications use stainless steel pleated filter cartridges?

A: They are commonly used in water treatment, chemical processing, and food production. Their resistance to corrosion and high temperatures is particularly valued. These filters ensure reliable operation in tough conditions.

Q: What are the main benefits of using a stainless steel pleated filter cartridge?

A: The main benefits include high filtration efficiency, durability, and reusability. They withstand extreme temperatures and harsh chemicals. This makes them a cost-effective choice for industrial filtration needs.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: